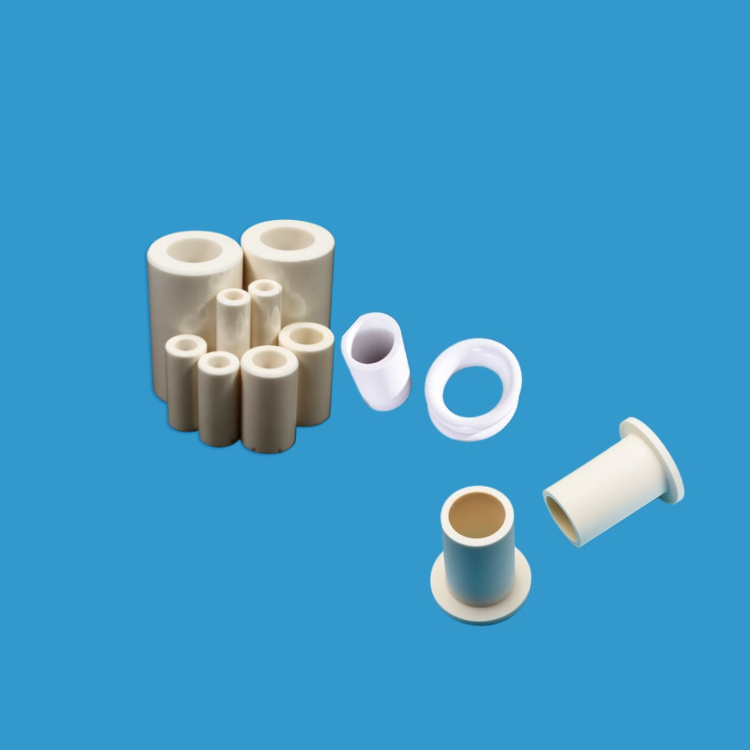

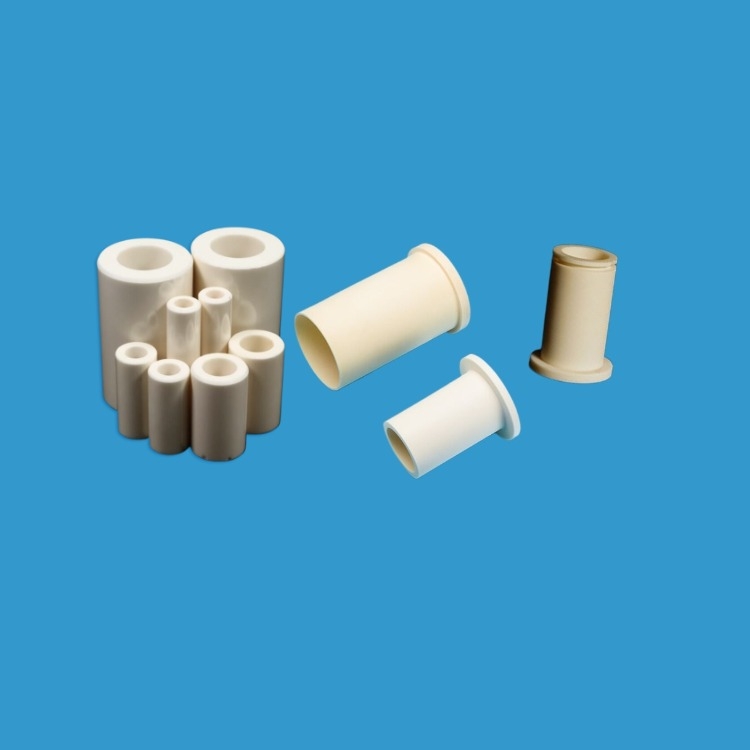

Alumina ceramic bushing high purity 95 to 99.7 al2o3 aluminum oxide ceramic bushing

Ceramic materials are available:Alumina (Al2O3) 95% to 99.99% ...etc

General sizes:6 mm12 mm10 mm8 mm14 mm12 mm10 mm16 mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

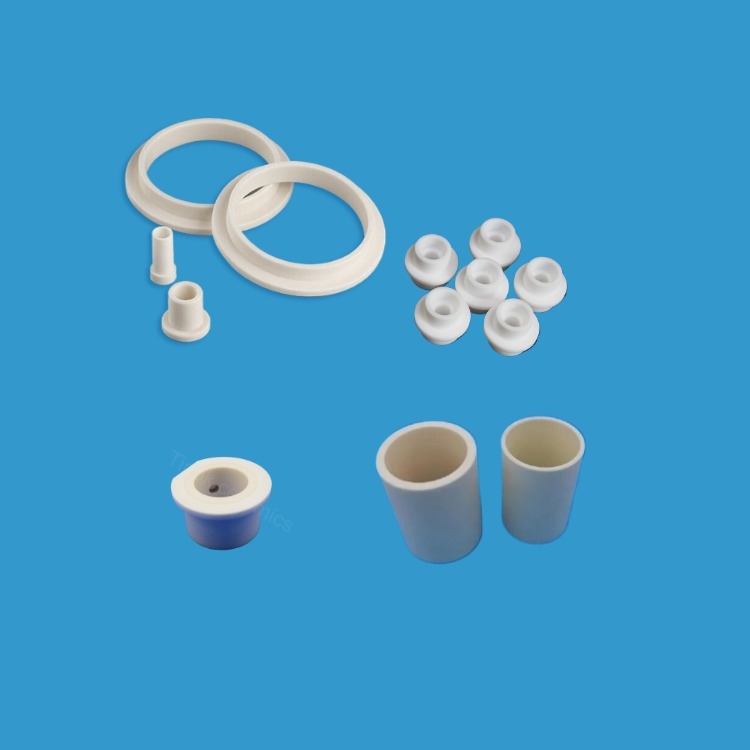

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Alumina ceramic bushing is mainly made of alumina ceramic, our alumina ceramic bushing can choose the alumina ceramic composition of 95% to 99.7% al2o3. alumina ceramic bushings are widely used in industrial production fields, such as bearings, valves and other mechanical parts. Metal bushings have excellent corrosion resistance and strength, and can be improved by surface activation treatment.

Alumina ceramic bushing conventional size parameters

Nominal aperture d ranges from 11.99 mm to 22.23 mm, corresponding outer diameter D sizes range from 15.49 mm to 30.18 mm, length sizes range from 8.41 mm to 14.39 mm, and maximum length sizes range from 47.63 mm to 76.20 mm.

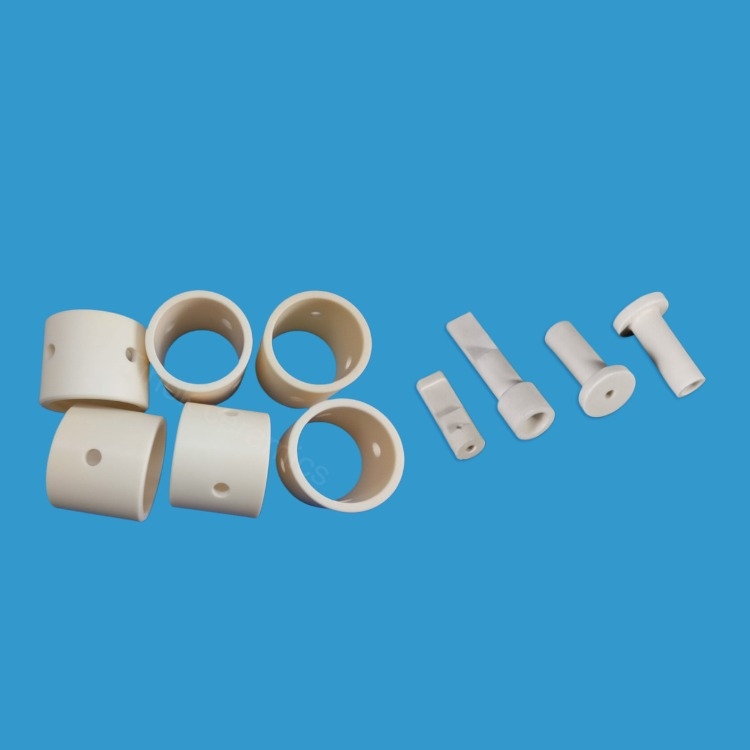

Us supports customization of different types alumina ceramic bushing

Alumina ceramic bushing type

The alumina ceramic bushing is a cylindrical component designed to support loads on the shaft, providing extremely low frictional motion by sliding on the rod or shaft. The main types of alumina ceramic bushings include sleeve and flanged alumina ceramic bushings, where flanged alumina ceramic bushings can handle combined loads, while sleeve alumina ceramic bushings are suitable for simple axial or radial loads.

Sleeve alumina ceramic bushing

Sleeve alumina ceramic bushings are the most basic type and are suitable for simple axial or radial loads. They can be threaded to an inner or outer surface to suit various assembly conditions.

Flange alumina ceramic bushing

Flange alumina ceramic bushings are used when designed with flanges and can handle combined loads. They are often used in applications that require higher carrying capacity.

Method of using alumina ceramic bushing

1. Select the appropriate alumina ceramic bushing

When choosing alumina ceramic bushing, it should be considered according to the material, medium, temperature, pressure and other factors used. In general, different types and specifications of alumina ceramic bushings are suitable for different connection methods, such as flanges, threads, welding, etc.

2. Install the alumina ceramic bushing

When installing the bushing, first clean and check whether there is foreign matter and damage inside the bushing, and then connect the alumina ceramic bushing to the pipe according to the connection method.

3. Maintain the alumina ceramic bushing

In the process of use, the condition of alumina ceramic bushing should be regularly checked. If there is any odor, color change, corrosion and other phenomena, it should be replaced immediately. Clean the inside of the bushing regularly to keep it dry and clean.

Inner Diameter | Outer Diameter | Length |

0.030 to 0.036 inches | 0.378 inches | 0.515 inches |

0.032 to 0.038 inches | 0.250 inches | 0.378 inches |

0.043 to 0.047 inches | 0.378 inches | 0.515 inches |

0.044 to 0.052 inches | 9.60 mm | 13.08 mm |

1.18 to 1.32 mm | 0.378 inches | 0.515 inches |

0.048 to 0.052 inches | 0.378 inches | 0.515 inches |

0.053 to 0.061 inches | 0.378 inches | 0.515 inches |

0.056 to 0.064 inches | 0.378 inches | 0.515 inches |

0.065 to 0.073 inches | 0.378 inches | 0.515 inches |

0.054 to 0.060 inches | 0.378 inches | 0.515 inches |

0.074 to 0.078 inches | 0.378 inches | 0.515 inches |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.