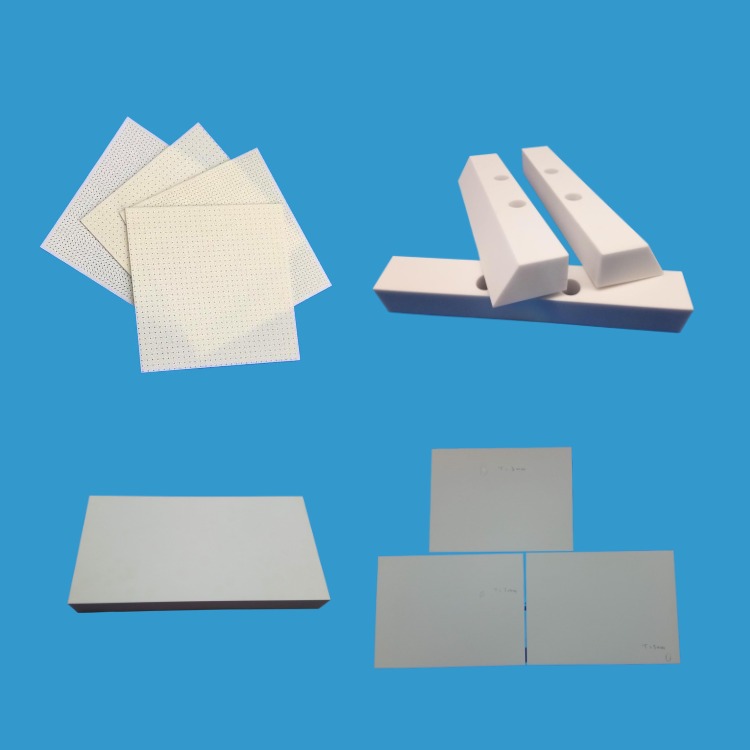

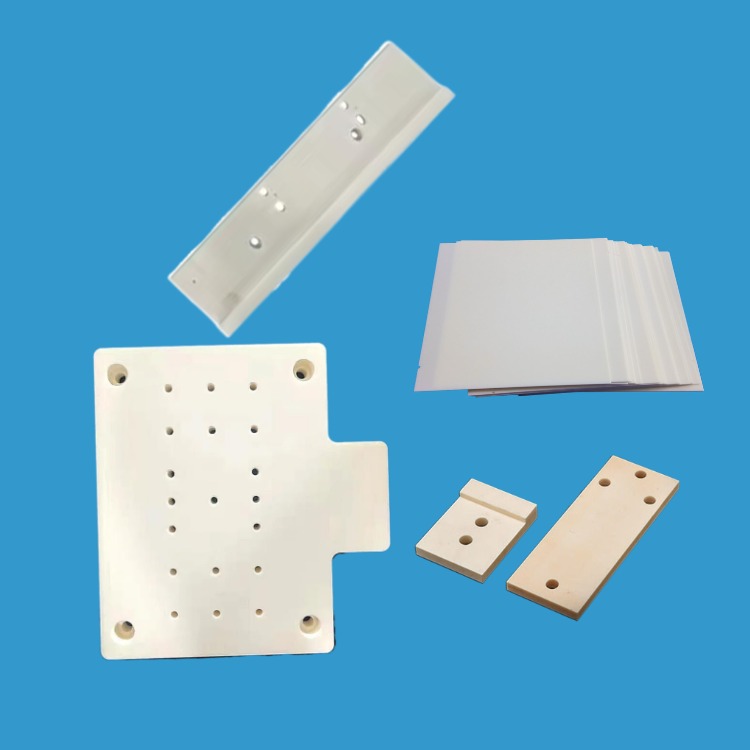

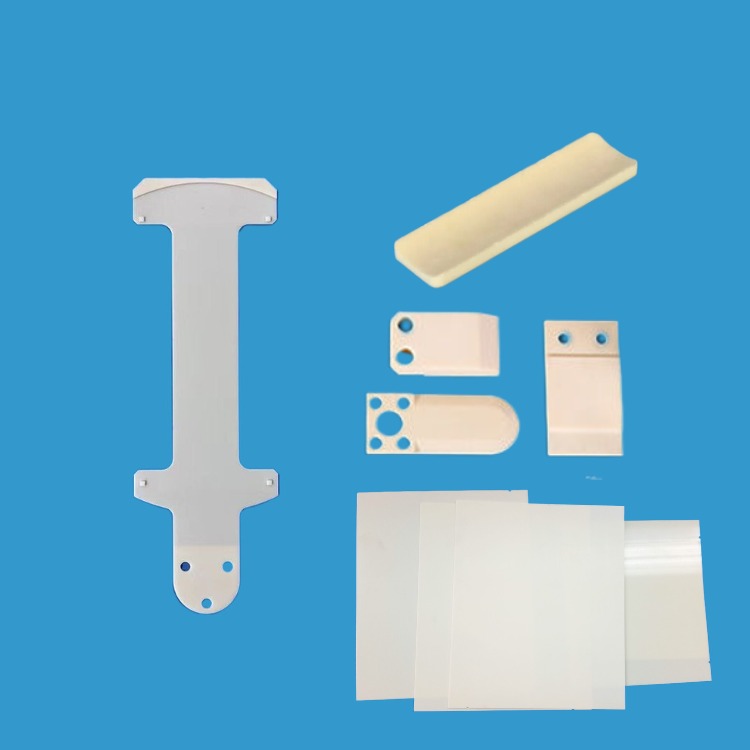

Alumina ceramic plate High Mechanical Strength Al2O3 99.7 99.5 99.9 purity alumina ceramic plate

Ceramic materials are available:Alumina (Al2O3) ...etc

The thickness is generally 0.254mm, 0.385mm, and 1.0mm/2.0mm/3.0mm/4.0.mm.

Delivery times:2 -25 days(depends on the quantity)

Maximum accuracy: 0.001mm-- tolerance: 0.001mm... etc

Surface Treatment:Normal,polished,diamond polished,matte

Features:Excellent insulation, Wear Resistance,Extreme Temperature Stability...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

As a common component, alumina ceramic plates play a vital role in different machinery and equipment. There are many kinds of alumina ceramic plates with different materials, sizes and functions.

Ceramic properties of alumina ceramic plate

Excellent insulation

High Mechanical Strength

Outstanding Electrical and Electronic Properties

Wear Resistance

Extreme Temperature Stability

Resistant to Corrosion and Chemical Attack

Alumina ceramic plates have a variety of important roles in engineering and mechanical fields, mainly including:

1. Sealing effect: alumina ceramic plate is usually used to provide a seal at the joint of two planes to prevent leakage of liquid, gas or other media. They can fill the gaps between the connectors, ensuring that the joint maintains a reliable sealing performance.

2. Bearing and dispersing pressure: alumina ceramic plate can be used to withstand and disperse the pressure at the joint to prevent the connector from deformation or damage due to excessive pressure.

3. Prevent loosening: The alumina ceramic plate plays a locking and preventing loosening role in the mechanical connection, especially in the vibration environment, which can effectively maintain the stability of the connector.

4. Fill the uneven surface: In the case of uneven or defective connection surface, alumina ceramic plate can fill the surface defect to ensure a tight connection and improve the sealing effect.

5. Heat conduction: alumina ceramic plate has good heat conduction performance and can be used to promote heat transfer and heat dissipation, such as applications in engines, radiators and other components.

6. Fill deformation defects: When there are deformation defects on the surface of the connector, the alumina ceramic plate can help fill these defects to ensure the integrity and stability of the connection.

Alumina ceramic plate performance

1, wide range of application. Can withstand high temperature, high pressure and adapt to ultra-low temperature or vacuum use.

2, the application compensation ability is strong. The sealing performance is stable and reliable at stations with high temperature and high pressure fluctuations.

3, has good sealing performance.

4, easy to use and install.

alumina ceramic plate sizes chart tables

Length | Width | Thickness |

127 | 178 | 0.25mm |

114 | 114 | 0.38mm |

114 | 114 | 0.5mm |

127 | 127 | 0.5mm |

138 | 190 | 0.5mm |

83 | 83 | 0.65mm |

100 | 100 | 0.65mm |

109 | 130 | 0.65mm |

114 | 114 | 0.65mm |

138 | 190 | 0.65mm |

240 | 280 | 0.65mm |

114 | 114 | 0.8mm |

83 | 83 | 1mm |

50 | 100 | 1mm |

100 | 100 | 1mm |

109 | 130 | 1mm |

114 | 114 | 1mm |

127 | 127 | 1mm |

130 | 170 | 1mm |

135 | 135 | 1mm |

138 | 190 | 1mm |

144 | 244 | 1mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.