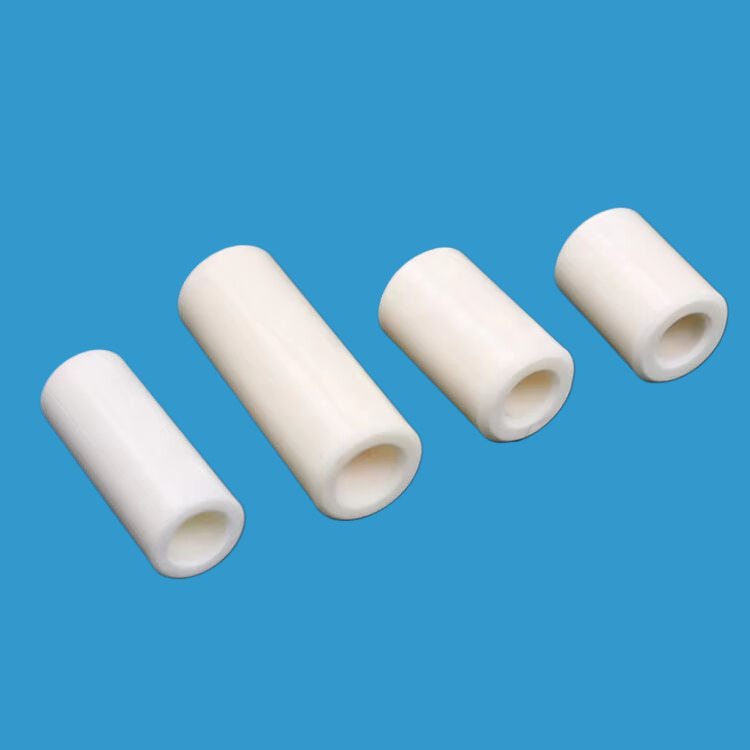

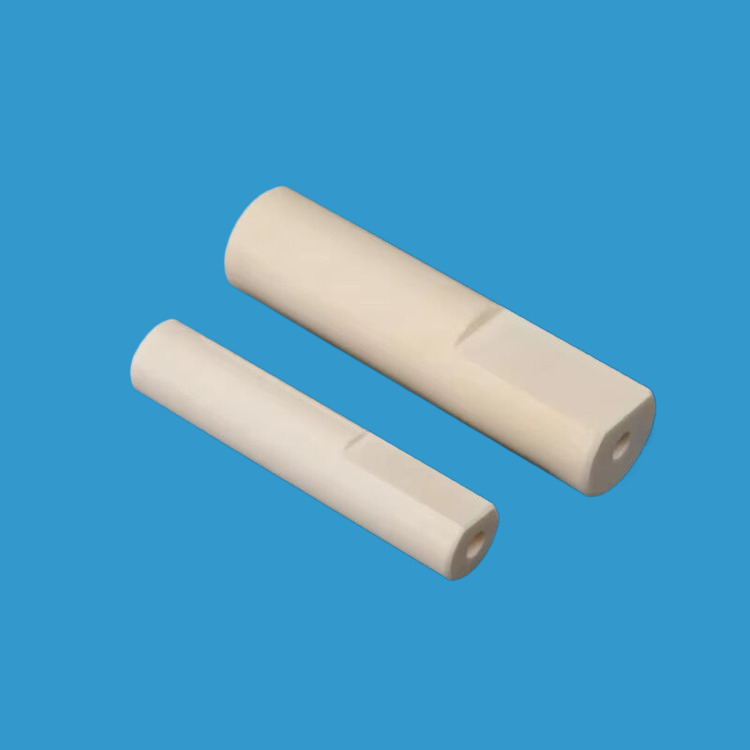

Alumina ceramic plunger low thermal expansion Al2O3 Aluminium oxide ceramic plunger

Ceramic materials are available:Alumina ceramic (Al2O3 purity 95% to 99.99%)

General sizes:Length max up to 150mm

Rockwell Hardness:92HRA

Thermal Expansion Coefficient: 7.6 10-6/°C

Features:high hardness, wear resistance, high temperature resistance, corrosion resistance...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

alumina ceramic plunger are made of alumina (Al2O3) ceramics. As a fine ceramic material, alumina ceramics are widely used in many industries. Alumina rods have excellent electrical insulation, high chemical resistance and low thermal expansion.

Material: High purity alumina +316 stainless steel ceramic

Molding process: isostatic pressing, high density

Application: For food, feed canning, clean, environmental protection, high efficiency

Cylindricity of the inner hole: 0.002mm

Straightness of inner hole: 0.0001mm

Safe and reliable: the use of the latest technology processing, to ensure the consistency of the product, no card pump, no leakage

Alumina ceramic plunger features:

(1) Alumina ceramic plunger using high-performance technology ceramic material, with high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Ensure reliable material performance.

(2) The surface of the inner cavity adopts a fluid structure, without dead corners and grooves. The surface of the inner cavity and the surface of the plunger are processed to the mirror surface by advanced high-precision internal and external cylindrical grinding machine, and the external surface is polished by vibration, which is convenient for cleaning and disinfection.

(3) The pump body structure is finely sealed with the product structure for easy disassembly.

(4) Safe and reliable processing with the latest technology to ensure the consistency of the product, no card pump, no leakage.

(5) Green low-carbon through low-carbon awareness, to achieve standardization of specifications, application of universal.

Alumina ceramic plunger is a kind of ceramic product made of alumina, which has the characteristics of high hardness, high temperature resistance and corrosion resistance. It is widely used in the industrial field of seals, valves, pumps and sensors and other equipment, can effectively improve the durability of equipment and work efficiency.

Application of alumina ceramic plunger in sealing field:

Alumina ceramic plunger plays a key role in the pump sealing field. Due to its high hardness and wear resistance, alumina ceramic plungers can effectively prevent leaks and reduce friction losses, improving sealing performance and equipment service life. At the same time, it also has corrosion resistance and is suitable for sealing needs under various environmental conditions.

Alumina ceramic plunger in the valve and pump application:

Alumina ceramic plungers are also widely used in valves and pumps. It can be used as a key component of valves or pumps to control the flow and pressure of fluids. Due to their high hardness and wear resistance, alumina ceramic plungers provide reliable sealing performance and reduce the frequency of maintenance and replacement of equipment.

Alumina ceramic plunger in the sensor application:

Alumina ceramic plungers can also be used in sensors to detect and convert physical quantities. Due to its high hardness and stability, alumina ceramic plungers can provide stable and accurate sensing performance in complex environments, and are widely used in pressure sensors, temperature sensors and other fields.

Alumina ceramic plunger parameter

length(mm) | diameter(mm) |

42 | 4 |

73 | 5 |

43 | 20 |

91 | 15 |

56 | 10 |

77 | 2 |

109 | 7 |

55 | 5 |

92 | 2 |

49 | 9 |

101 | 17 |

83 | 15 |

66 | 11 |

72 | 18 |

65 | 4 |

100 | 14 |

64 | 4 |

98 | 19 |

65 | 7 |

60 | 4 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.