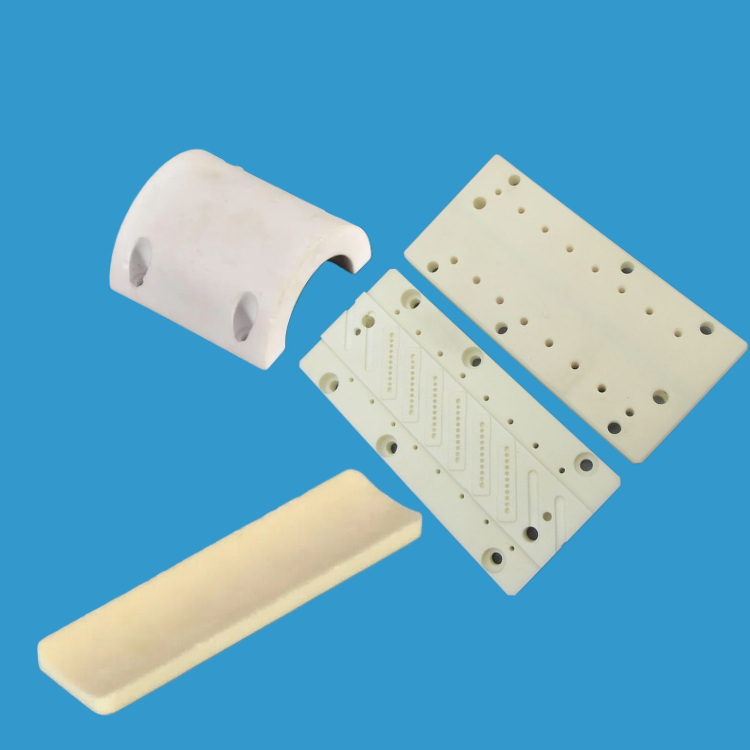

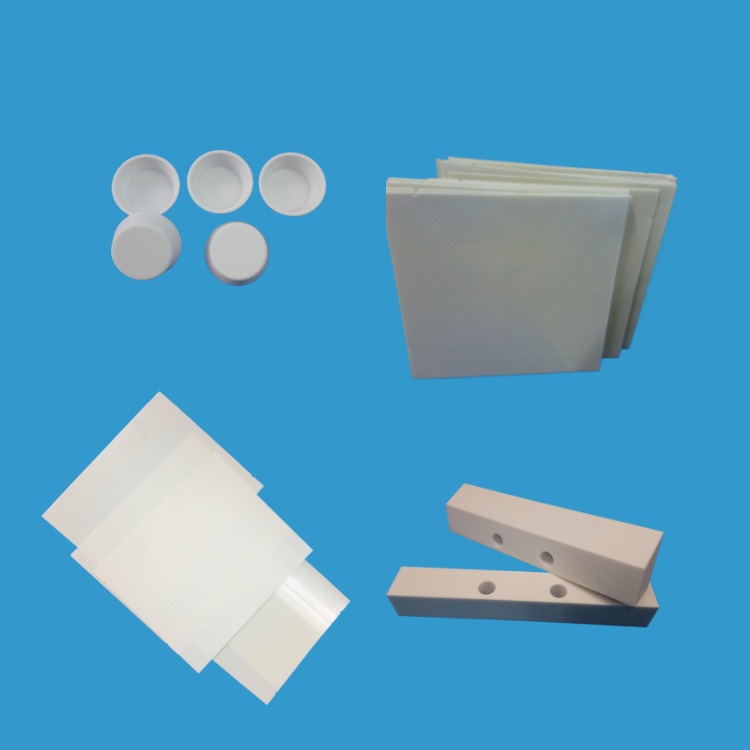

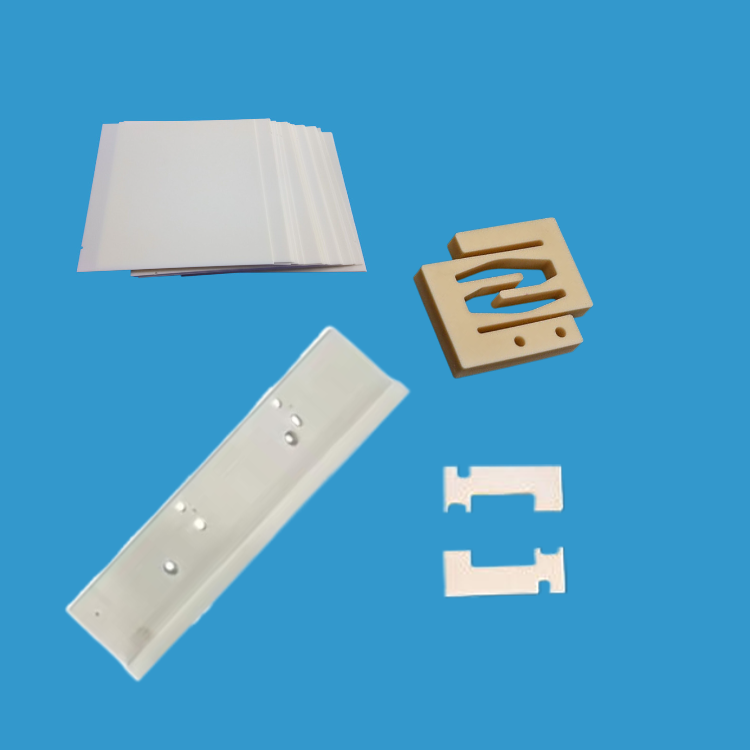

Alumina ceramic sheet 95% 99% al2o3 high purity alumina sheet ceramic plate parts

Ceramic materials are available:Alumina (Al2O3) 95% to 99.99% ...etc

General sizes:138*190*1mm;50*50*10mm;80*80*5mm...

Delivery times:2 -25 days(depends on the quantity)

Maximum accuracy: 0.001mm-- tolerance: 0.001mm... etc

Compression Strength>508 MPa

Features:Good wear-resistant, sealing ability,Good tensile strength...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Alumina ceramic sheet is made of alumina ceramic material with high precision density and high hardness.

Alumina ceramic sheet are usually used for precision equipment or precision hardware parts adjustment, or as a pad, sometimes called precision gap sheet. Alumina ceramic sheets are widely used in a variety of industrial applications, including construction, machinery, automotive and other industries, and are favored for their smooth surface, light weight and good corrosion resistance.

In addition, there are many types of alumina ceramic sheets, such as ordinary alumina ceramic gaskets, flanged alumina ceramic sheets, corrugated alumina ceramic sheets, oval alumina ceramic sheets, etc. Each type has its specific application scenarios and advantages, suitable for different working environments and needs.

The role of alumina ceramic sheet

First, electric proof, sealed, wear-resistant

Alumina ceramic sheet are widely used in automobiles, mechanical equipment, home appliances, electronic products and other fields, among which the most common alumina ceramic sheet are used for insulating electricity and wear resistance. In industrial equipment and other high temperature, high pressure or with a certain corrosive environment, alumina ceramic sheet can play the role of isolation, sealing and waterproof, but also effectively resist some small particles, so that mechanical equipment in good condition.

Second, shock buffering and wear resistance

In the joint of high-speed rotating objects such as mechanical equipment, alumina ceramic sheet can also play a role in shock absorption and buffering. When the rotating object is in a state of high-speed motion, the alumina ceramic sheet can absorb and disperse energy, reduce the generation of wear-resistant vibration and noise, thereby improving the efficiency of mechanical equipment.

Three, padding height gap

Alumina ceramic sheets can also be used to fill the gaps in mechanical equipment or parts, play the role of padding, making mechanical equipment and accessories more tight, so as to ensure its normal operation. In some special cases, alumina ceramic sheets can also be used to adjust, calibrate and balance the position and pressure of mechanical equipment.

Processing Service of Alumina ceramic sheets

Bending, Welding, Cutting, Punching, Decoiling, Moulding, customization

Alumina ceramic plates of ceramic features:

1. High density, high purity.

2. Good wear-resistant, sealing ability.

3. Good tensile strength.

4. Good high temperature tolerance.

5. Excellent cold crushing and thermal shock resistance.

6. Excellent chemical stability and corrosion resistance.

7. No staining for long-term use.

Alumina ceramic plates of Application:

1.Mines, steel, electricity,Chemical industry, cement,Medical field, environmental field

2.It is used in coal transport, material transport, pulverization, ash discharge, dust removal system and other mechanical equipment with large wear Mines, steel, electricity

Alumina ceramic sheet sizes chart:

Length | Width | Thickness |

220mm (8.66in) | 220mm (8.66in) | 5mm (0.2in) |

216mm (8.5in) | 102mm (4.01in) | 5mm (0.2in) |

208mm (8.19in) | 110mm (4.33in) | 5mm (0.2in) |

152mm (6in) | 152mm (6in) | 5mm (0.2in) |

150mm (5.91in) | 80mm (3.15in) | 4mm (0.16in) |

107mm (4.21in) | 53mm (2.09in) | 4mm (0.16in) |

102mm (4in) | 76mm (3in) | 6mm (0.24in) |

102mm (4in) | 25mm (0.98in) | 1mm (0.04in) |

90mm (3.54in) | 65mm (2.56in) | 6mm (0.24in) |

90mm (3.54in) | 45mm (1.77in) | 4mm (0.16in) |

60mm(2.36in) | 40mm (1.57in) | 1mm (0.04in) |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.