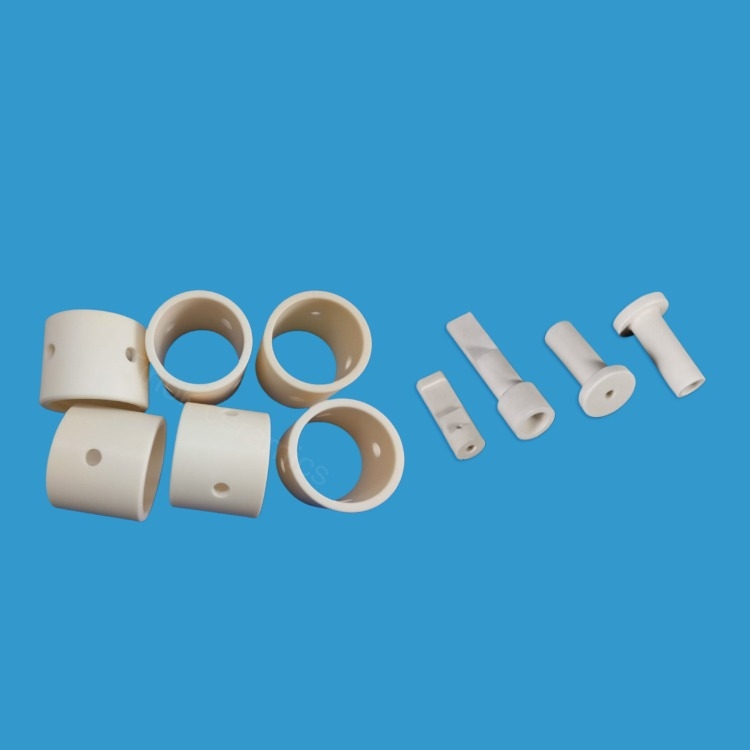

Ceramic bushing insulators low thermal conductivity alumina ceramic insulators

Ceramic materials are available:Zirconia, Alumina, Silicon nitride and machinable ceramic...etc

General sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Tolerance: 0.001mm... etc

Minimum aperture: The minimum can be processed 0.07mm

Features:Excellent insulation ,security , long working life...

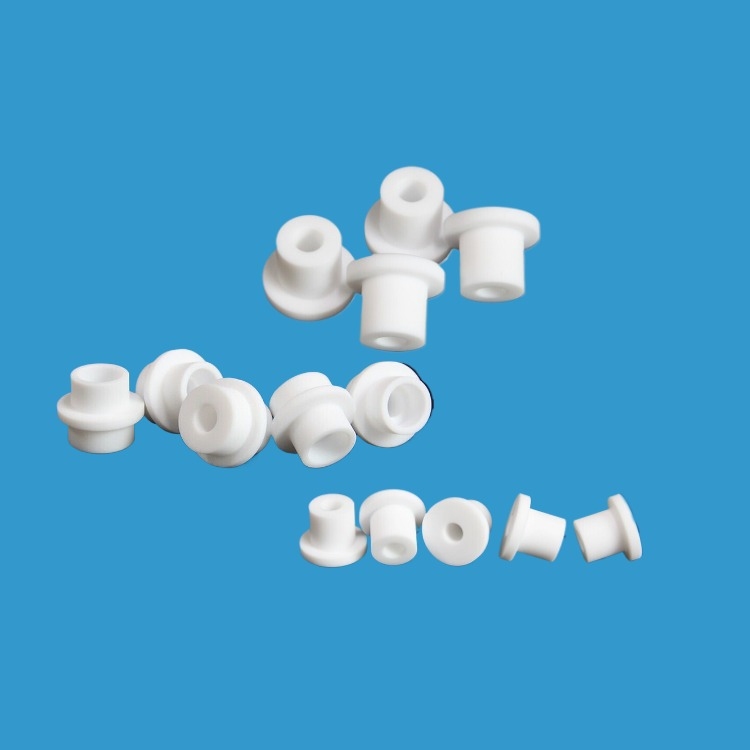

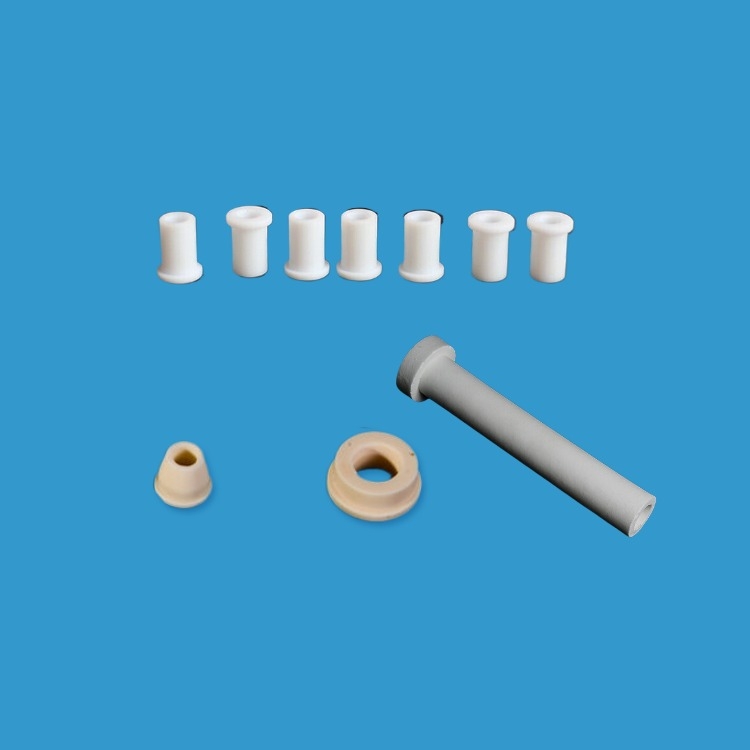

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

As an insulating material, ceramic bushing insulator has many characteristics that traditional materials do not have, so it has been widely used in the field of electrical insulation. Ceramic bushing insulators are used in high voltage insulation materials, capacitors, high frequency electronic components, electronic circuit boards, etc.

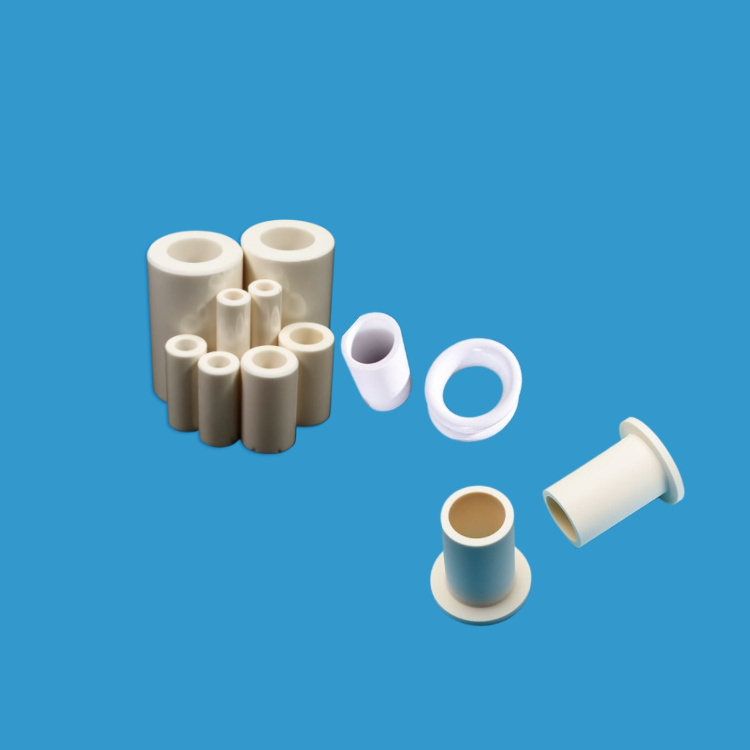

Type of ceramic bushing insulator

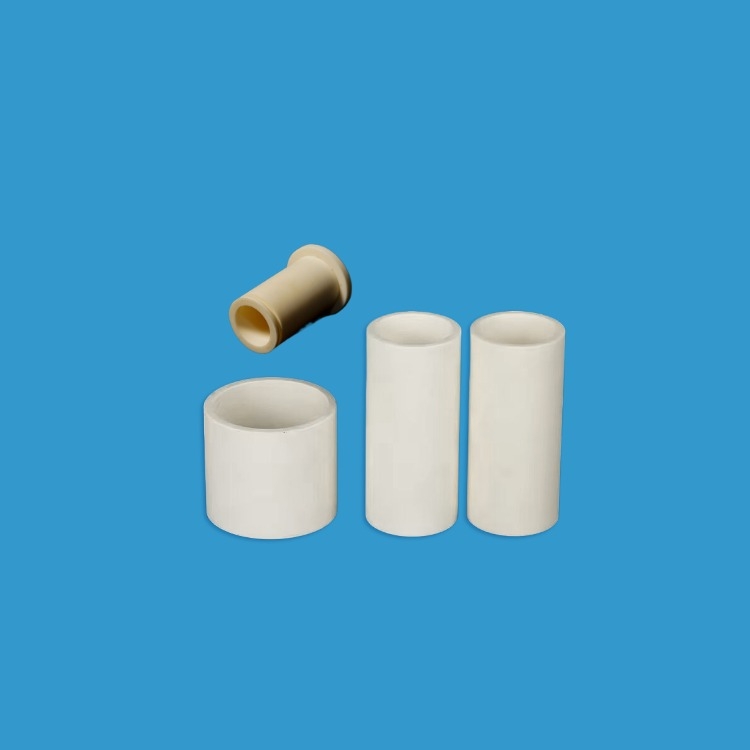

Sleeve bushing ceramic insulator

Flange bushing ceramic insulator

Standard straight tube bushing ceramic insulator

Spherical bushing ceramic insulator

Special specification ceramic insulator

1. High voltage insulation material

Ceramic bushing insulators have the characteristics of high dielectric constant, dielectric strength and corona resistance, so they are excellent in high voltage insulation materials. In addition, its strength and toughness are also better than traditional materials, and it is more suitable for use in extreme environments such as high temperature, high pressure and high humidity. Therefore, it is widely used in power generation, power transformation, cable lines and many other fields.

Insulation properties of ceramic bushing insulators

Ceramic is a very good insulating material with high insulating properties. The insulation performance of ceramic bushing insulator is mainly manifested in the following aspects:

1. High resistivity: Generally, the higher the resistivity of the insulation material, the better its insulation performance. Ceramics have a high resistivity and can effectively prevent the loss of current.

2. Low dielectric constant: dielectric constant is the electrical properties of a material displayed in the electric field, the lower it is, the better the insulation performance of the material. Ceramic has a very low dielectric constant, ceramic bushing insulator can effectively isolate the electric field.

3. High voltage resistance: ceramics can withstand high voltage, not easy to breakdown due to high voltage. This makes the ceramic bushing insulator can still play a good insulation performance in the environment of high voltage and high electric field strength.

4. Good heat resistance: the melting point of ceramics is very high and can withstand high temperature environment. In a high temperature environment, other insulating materials are easy to fail, but ceramic bushing insulators can still maintain good insulation performance.

The application of ceramic bushing insulator in various fields

Due to the excellent insulation performance of ceramic bushing insulators, ceramic bushing insulators are widely used in various fields:

1. Electronic field: ceramics can be used to make capacitors, inductors, tubes, transistors and other electronic components. Among them, ceramic bushing insulator is one of the most widely used and largest ceramic products.

2. Power field: Power equipment (such as transformers, circuit breakers, fuses, cables, etc.) need to have good insulation performance, so ceramic bushing insulators have been widely used.

3. Chemical industry: there will be high temperature and high pressure environment in the chemical industry system, ceramics because of its excellent high temperature resistance and corrosion resistance, so ceramic bushing insulators have been widely used.

4. Other fields: Ceramic bushing insulators can also be used in thermal industry, environmental protection, medical and other fields.

ceramic bushing insulators sizes chart

| Inside diameter: | Outside diameter: | length: |

| 3mm | 4-3/5" | 2-1/16" |

| 5mm | 5mm | 6mm |

| 6mm | 6.8mm | 7mm |

| 7mm | 8mm | 10mm |

| 8mm | 10mm | 12mm |

| 10mm | 11mm | 15mm |

| 12mm | 12mm | 16mm |

| 14mm | 13mm | 20mm |

| 15mm | 14mm | 21.5mm |

| 16mm | 16mm | 22mm |

| 17mm | 17mm | 23mm |

| 18mm | 18mm | 24.5mm |

| 20mm | 19mm | 25mm |

| 22mm | 20mm | 26mm |

| 24mm | 22mm | 28mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.