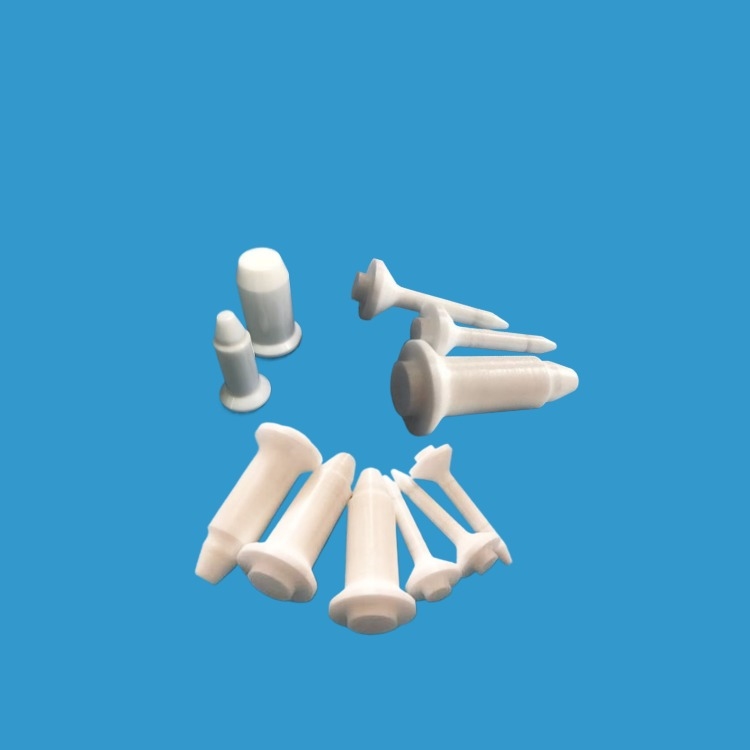

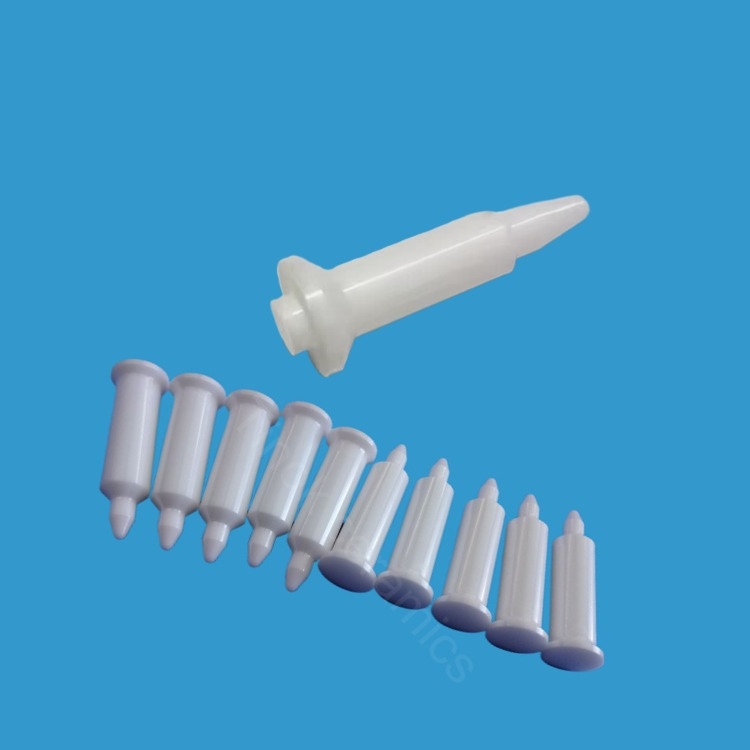

Ceramic centering pin wear resistant alumina zirconia ceramic pins

Ceramic materials are available:alumina,zirconia and other materials...etc

The length ranges from 10mm to 50mm

Delivery times:2 -25 days(depends on the quantity)

Vickers hardness(HV):14Gpa

Tolerance: 0.001mm... etc

Features:high hardness, high wear resistance, good insulation...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic centering pin is a fastener used on machines, equipment and tools, its main role is to use the mutual matching of the boss and the groove to accurately locate, and the position of the matching parts is fixed during the assembly process. Ceramic centering pin are generally made of alumina,zirconia and other materials, and their shapes and sizes are also different, which can be customized according to the specific application needs.

The function of the ceramic centering pin is not limited to positioning, it can also play a role in preventing parts from loosening, enhancing the stability of assembly, improving wear resistance and extending the service life.

Advantages of ceramic centering pins

1 high temperature strength

2 superior thermal shock resistance

3 excellent wear resistance

4 good fracture toughness

5 mechanical fatigue and creep resistance

6 Excellent non-wetting property with good oxidation resistance

Ceramic centering pin size

1. Diameter 0.125 inches (3.17mm), length 0.5 inches (12.7mm).

2, diameter 0.625 inches (15.87mm), length 0.625 inches (15.87mm).

3. Diameter 0.375 inches (9.52mm), length 0.75 inches (19.05mm).

4, Diameter 0.25 inches (6.35mm), length 0.875 inches (22.22mm).

The application scenario of ceramic centering pins

Ceramic centering pin are widely used in the field of machinery manufacturing, as well as automotive, aerospace and other industries. Here are some common application scenarios:

1. Mechanical manufacturing: In the process of fixing and connecting the machine and equipment, it is often necessary to use ceramic centering pin to ensure the position and placement of the components.

2. Automobile: Ceramic centering pins are used in automobile engine, brake system, tire bearings and other parts to ensure the safety and stability of the car during operation.

3. Aerospace: In the aerospace field, the use of ceramic centering pin is more common. For example, in the manufacture of aircraft, the various components need to be accurately integrated and positioned, and the positioning pin becomes an indispensable part.

The ceramic centering pin is a mechanical component used to accurately determine the relative Ceramic centering pin of a component and has the following important roles:

1. Positioning and fixing: ceramic centering pin can ensure that two or more parts accurately maintain relative positions during assembly to prevent dislocation or movement.

2. Improve assembly accuracy: Ensure the accuracy and consistency of assembly, thereby improving the quality and performance of the overall product.

3. Repeated positioning: accurate assembly can be achieved many times, ceramic centering pin suitable for mass production.

4. Transmission force and torque: In some cases, ceramic centering pin can also bear a certain force and torque transmission function.

5. Ensure processing accuracy: ceramic centering pin is used to locate the workpiece in the machining process, making the processing operation more accurate and reliable.

Ceramic centering pin size table

Outer Diameter | Length |

(mm) | (mm) |

8.3 | 340 |

8.6 | 210 |

9 | 110 |

11 | 95 |

14 | 84 |

16.26 | 340 |

19.05 | 210 |

19.69 | 180 |

27.94 | 360 |

5.38 | 440 |

6.35 | 210 |

6.71 | 110 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.