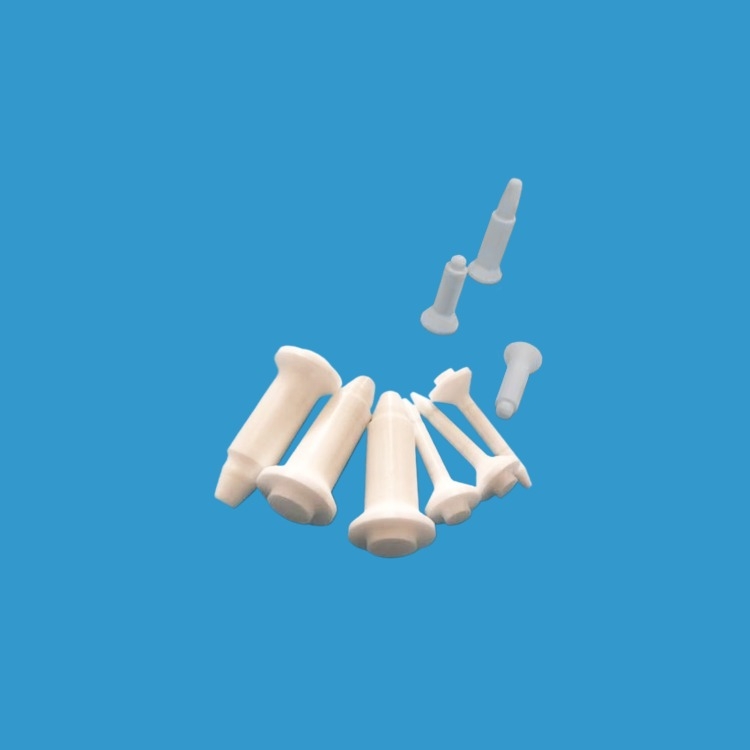

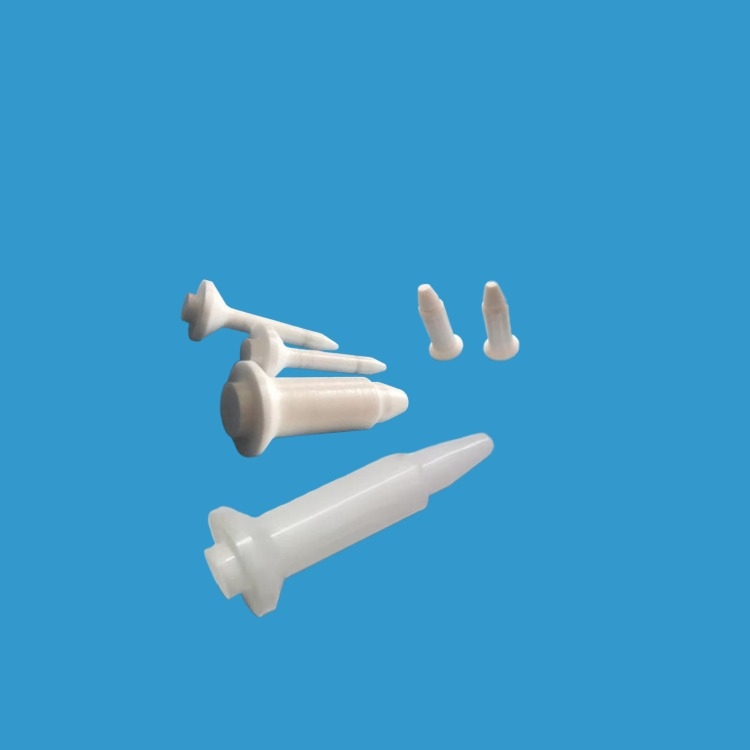

Ceramic dowel pin custom heat resistant high strength zirconia ceramic pins

Ceramic materials are available:zirconia,Si3N4 ...etc

General diameter sizes:Diameters and lengths are usually between 3mm and 25mm, with tolerances between ±0.01mm and ±0.05mm

Roundness:0.002mm

Surface roughness:Ra0.1... etc

Feature :High hardness, High strength, High temperacture

Sample:Available

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic dowel pin is a cylindrical fixing device that is mainly used to determine the relative position between two parts and ensure that they remain stable during movement or stress. Its main feature is that it has an accurate size and shape in order to precisely match the holes on the part.

Properties of Ceramic dowel pin

* Good electrical insulation

* High mechanical strength

* Excellent wear resistance

* Excellent corrosion resistance

* Low dielectric constant

Sizes of Ceramic dowel pin

Length x Width in mm

1.8x1 / 2.4x2.4 / 2.5x2.5 / 4x4 / 5x5 / 6x6 / 7.5x5 / 8.5x8.5

9x8.5 / 9.5x2.8 / 9.6x5.5 / 10x2 / 10x4 / 10x4.5 / 10x5 / 12x4.5

Ceramic dowel pin are usually made of ceramic and are designed to be cylindrical with a fixed length and diameter. By inserting the hole, the dowel prevents the two parts from moving in any direction, thus ensuring that they remain in relative position.

Processing Service of Ceramic dowel pin

Cutting, Moulding, Grinding, Milling, Drilling, Lapping, Polishing, CNC, Laser

The types of ceramic dowel pin

Taper ceramic dowel pins, taper pins with internal thread, cylindrical ceramic dowel pins, cylindrical pins with internal thread, taper ceramic dowel pins with open tail, cylindrical pins with thread, elastic cylindrical ceramic dowel pins with straight grooves and light weights, pins with holes, taper pins with screw tail, cotter pins, etc.

Ceramic dowel pin size table

Outer Diameter | Length |

(mm) | (mm) |

3 | 5-20 |

4 | 10-30 |

5 | 10-40 |

6 | 10-50 |

8 | 10-60 |

10 | 20-70 |

12 | 20-80 |

14 | 20-90 |

16 | 30-100 |

18 | 40-100 |

20 | 50-100 |

22 | 50-100 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.