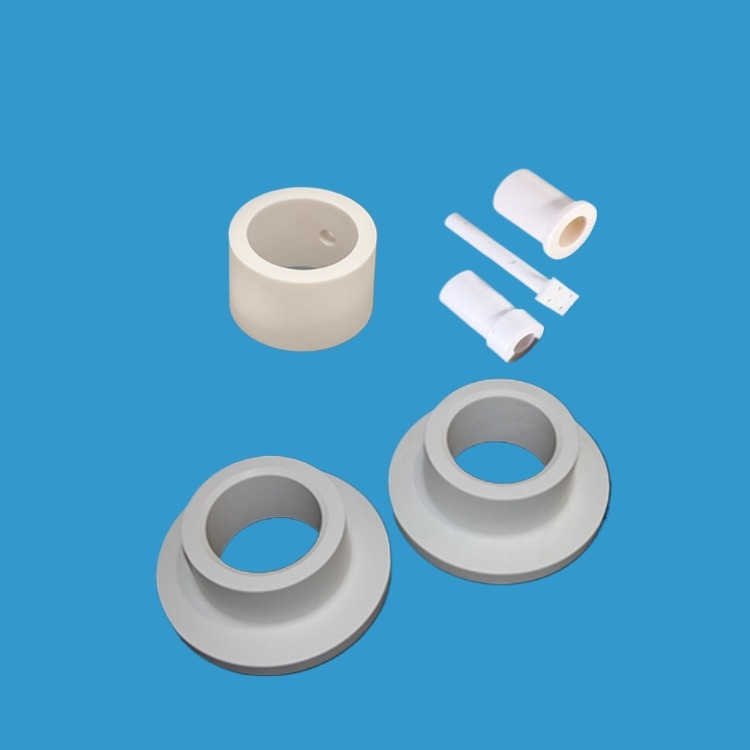

Ceramic guide bushing wear resistance ZrO2 or Al2O3 ceramic sleeve bushing

Ceramic materials are available:Zirconia (ZrO2) ,Alumina (Al2O3) 95% to 99.99% ...etc

General sizes:6 mm,12 mm,10 mm,8 mm,14 mm,16 mm,15 mm,18 mm,20 mm,22 mm,25 mm

Delivery times:2 -20 days(depends on the quantity)

Dimensional accuracy: up to 0.003; Inner hole: minimum 0.12x3mm;

Features:Wear resistance、Temperature resistance 、Thermal conductivity、High voltage、Hardness....

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

A ceramic guide bushing is a bush-like part, usually made of ceramic materials such as aluminum oxide, zirconia, and silicon nitride. The ceramic guide bushing is usually used to carry the force and over-load of the mating part, and ceramic guide bushing is used for the connection of the device or the swing drive.

A ceramic guide bushing is a cylindrical component designed to support loads on a equipment and operate between moving surfaces by sliding motion, providing extremely low frictional motion, excellent shock absorption work to minimize energy use, noise and wear. ceramic guide ceramic guide bushing is mainly used to reduce the wear, vibration and noise of the equipment, and has the effect of anti-corrosion, but also to facilitate the maintenance of mechanical equipment, simplify the structure and manufacturing process of the equipment.

Ceramic guide bushing for mechanical field:

Through ceramic guide bushing : the inner and outer cylinders are parallel, and there is a longitudinal hole groove in the middle, which is used to connect or fix other parts. It is widely used in various mechanical transmission systems.

Bevel ceramic guide bushing : the intersection line of the inner and outer cylindrical surface is 45°, mainly used for the occasions that need to bear transverse load, such as automobile steering mechanism, machine tool spindle, etc., has high torsional and seismic performance.

Conical ceramic guide bushing : the section is conical, the internal and external cylindrical cross line is helix, mainly used for gear transmission system, improve gear meshing efficiency and transmission accuracy, has good wear resistance and impact resistance.

Ceramic guide bushing sizes:

Standard straight ceramic guide bushing: the inner diameter (d) generally ranges from 6 mm to 150 mm, the outer diameter (D) generally ranges from 10 mm to 180 mm, and the length (L) generally ranges from 10 mm to 150 mm.

ceramic guide bushing sizes

ID Range | Outside Diameter | Length |

3.31-4.00mm | 7mm | 8mm |

7.032-7.023mm | 12mm | |

16mm | ||

4.01-5.00mm | 8mm | 8mm |

8.032-8.023mm | 12mm | |

16mm | ||

6.01-8.00mm | 12mm | 10mm |

12.039-12.028mm | 16mm | |

20mm | ||

8.01-10.00mm | 15mm | 12mm |

15.039-15.028mm | 20mm | |

25mm | ||

35.01-42.00mm | 55mm | 30mm |

55.072-55.053mm | 56mm | |

67mm | ||

42.01-48.00mm | 62mm | 30mm |

62.072-62.053mm | 56mm | |

67mm |

Us supports customization of different types ceramic guide bushing

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.