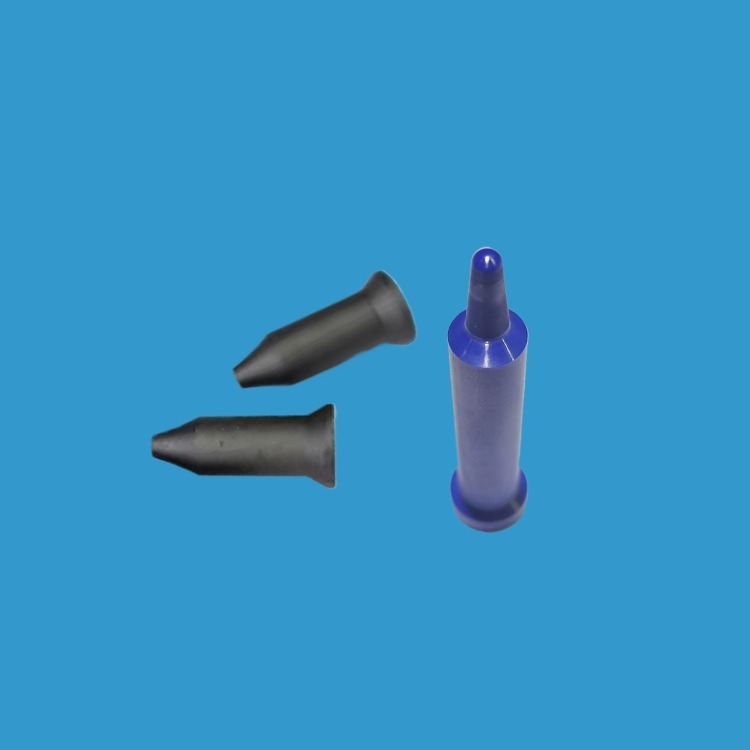

Ceramic guide pin alumina zirconia high hardness high wear resistance ceramic pins

Ceramic materials are available:AL2O3,ZrO2,Si3N4,Ceramic...etc

General diameter sizes:2mm, 3mm, 4mm, 5mm, 6mm and so on

Delivery times:2 -25 days(depends on the quantity)

Compressive strength:>1200Mpa

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:high hardness, high wear resistance, good insulation...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic guide pin is a kind of positioning pin made of ceramic material with many types and functions. They are commonly used to limit the free movement of items and ensure the precise position and fixation of components.

Ceramic guide pins are mostly made of alumina, zirconia or silicon nitride, etc. These materials have high hardness, high wear resistance, good insulation properties and high temperature resistance, making ceramic guide pins perform well in various industrial applications.

Ceramic guide pin advantage:

Good insulation performance

Excellent wear resistance ability

High temperature anti-oxidation performance

Good heat shock performance

The sizes of ceramic guide pins

Diameter: The diameter of the positioning pin varies according to actual requirements and application scenarios. Common diameter sizes are :2mm, 3mm, 4mm, 5mm, 6mm and so on

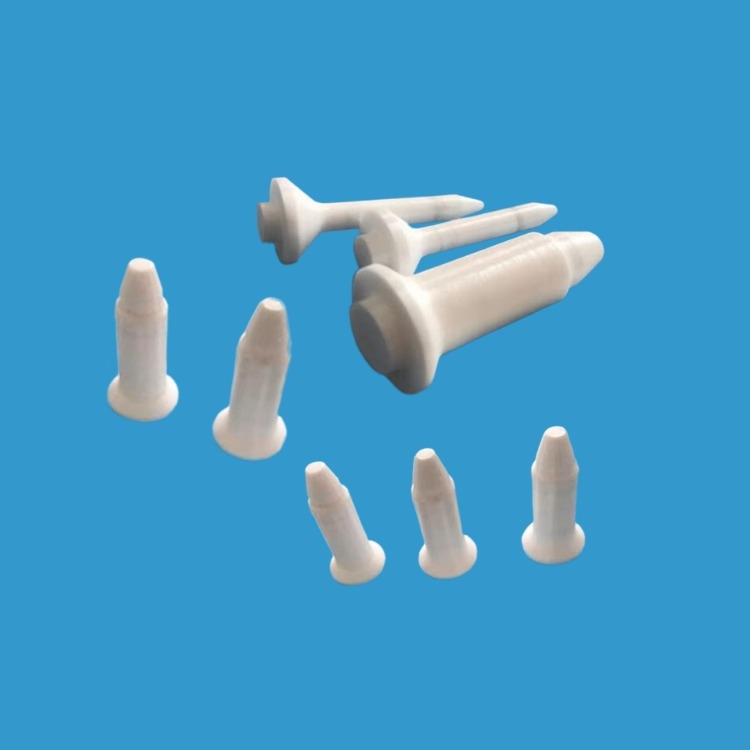

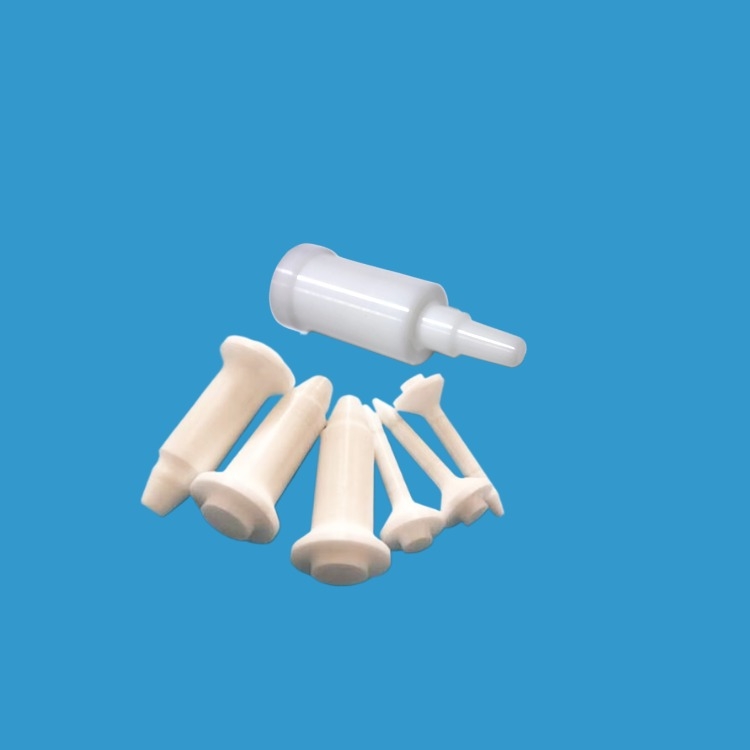

The types of ceramic guide pins

The types of ceramic guide pins include but are not limited to edge-to-edge guide pins, standard wilting guide pins, conical guide pins, fixed guide pins and interchangeable guide pins. Each type of dowel has its specific purpose and advantages to meet different fixing and positioning needs. For example, clipped ceramic guide pins are used to reduce unnecessary friction and wear, while interchangeable ceramic guide pins allow damaged parts to be replaced when needed, keeping the equipment in continuous operation.

Ceramic guide pins application

Ceramic guide pins are widely used, not only for mechanical fixing in industrial fields, but also play an important role in electronics, aerospace, automobile manufacturing and other fields. Their high temperature and wear resistance enables them to maintain stable operating performance under extreme conditions, thereby improving the reliability and service life of the equipment. In addition, the insulating properties of the ceramic guide pin also make it a place in the electrical field

Ceramic guide pin size table charts

Outer Diameter | Length |

(mm) | (mm)(in) |

0.28 | 10 |

0.51 | 19 |

0.56 | 150 |

0.61 | 210 |

2.44 | 230 |

0.28 | 80 |

0.51 | 20 |

0.56 | 34 |

0.61 | 53 |

2.44 | 75 |

3.18 | 90 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.