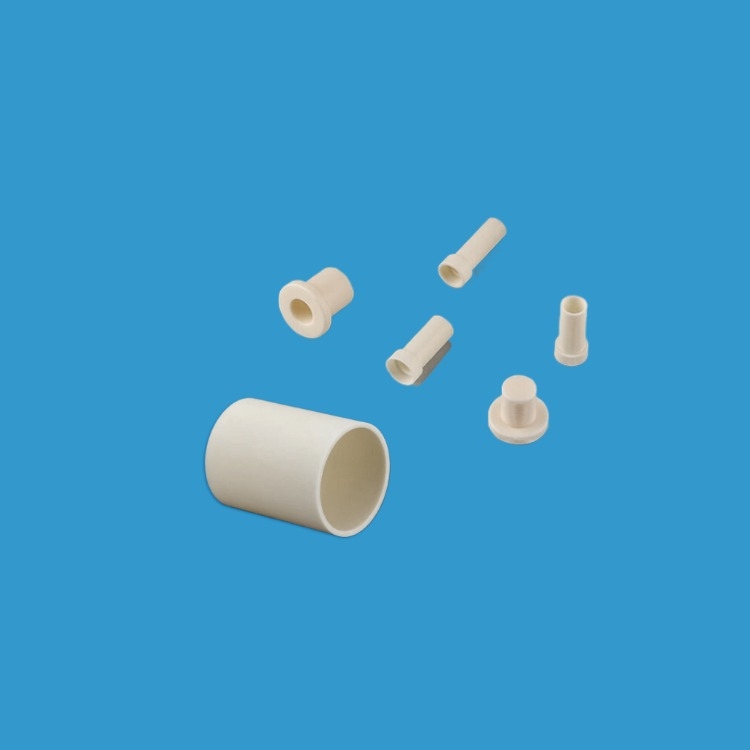

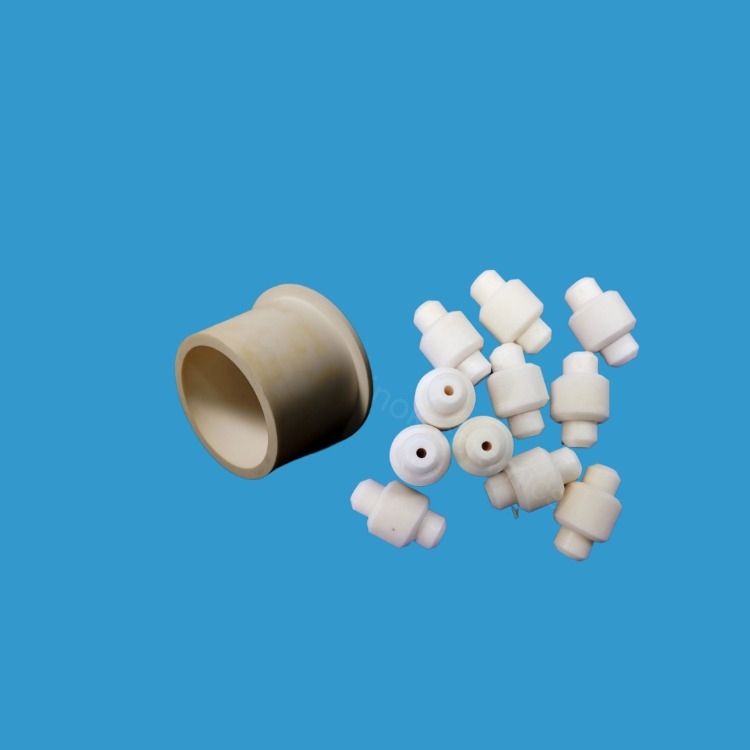

Ceramic beaded bushing high strength ceramic shoulder bushings with wear and friction resistance

Ceramic materials are available:Zirconia, Alumina, Silicon nitride and machinable ceramic...etc

General sizes:ID 2 to 25mm; OD 4 to 28mm

Tolerance: 0.001mm... etc

Thickness size: the minimum can be processed to 0.15mm;

Features:wear resistance and friction resistance...

Customized:Can be custom for special sizes and shapes

Delivery times:2 -25 days(depends on the quantity)

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic beaded bushing is a key component used to reduce wear and friction in mechanical equipment. It is made of high-strength, wear-resistant ceramic materials.

This ceramic beaded bushing is designed to have a beaded shoulder construction, i.e. a raised beaded is formed inside or outside the bushing. This ceramic beaded bushing structure provides better support and positioning functions, allowing it to withstand greater loads and pressures in mechanical equipment.

In addition to excellent wear resistance and friction resistance, the ceramic beaded bushing type also has corrosion resistance, high temperature resistance, self-lubrication and other features. It can operate stably in a variety of harsh working conditions, and will not pollute the environment.

Features of ceramic beaded bushing:

Good self-lubricating performance: Because ceramic beaded bushing internal ceramic material has self-lubricating characteristics, it has good self-lubricating performance, which can reduce friction loss and extend service life.

Low friction: The ceramic beaded bushing has the advantage of small friction, and there will be no problems such as oil loss.

Good wear resistance: The ceramic material used in the ceramic beaded bushing is of excellent quality and has extremely high wear resistance, so it can maintain stable performance and long life in high frequency use.

Easy installation: The beaded flange shape design makes the installation of ceramic beaded bushing easier, which can save installation time and labor costs.

Application of ceramic beaded bushing:

Transmission: In various transmission devices, such as gearboxes, chains, etc., standard ceramic beaded bushing can be used as support and lubrication components to provide stable lubrication, reduce the coefficient of friction, reduce mechanical failure and maintenance costs.

Automated production line: In the automated production line, various mechanical equipment needs high-precision and high-efficiency transmission components to ensure the stable operation of the production line. Standard ceramic beaded bushing has excellent wear resistance and self-lubrication, and can work stably in a variety of harsh environments for a long time to improve production efficiency and product quality.

Shipbuilding, metallurgy, chemical industry and other fields: in these fields, mechanical equipment often need to work in high temperature, high pressure, corrosion and other harsh environments, ceramic beaded bushing can provide reliable support and lubrication, to ensure the normal operation and maintenance of equipment.

ceramic headed bushing sizes

ID Range | Outside Diameter | Length |

4.01-5.00mm | 8mm | 8mm |

8.032-8.023mm | 12mm | |

16mm | ||

5.01-6.00mm | 10mm | 10mm |

10.032-10.023mm | 16mm | |

20mm | ||

15.01-18.00mm | 26mm | 16mm |

26.048-26.035mm | 28mm | |

36mm | ||

48.01-55.00mm | 70mm | 30mm |

70.078-62.059mm | 56mm | |

67mm | ||

55.01-63.00mm | 78mm | 35mm |

78.078-78.059mm | 67mm | |

78mm | ||

78.01-85.00mm | 105mm | 40mm |

105.101-105.079mm | 78mm | |

105mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.