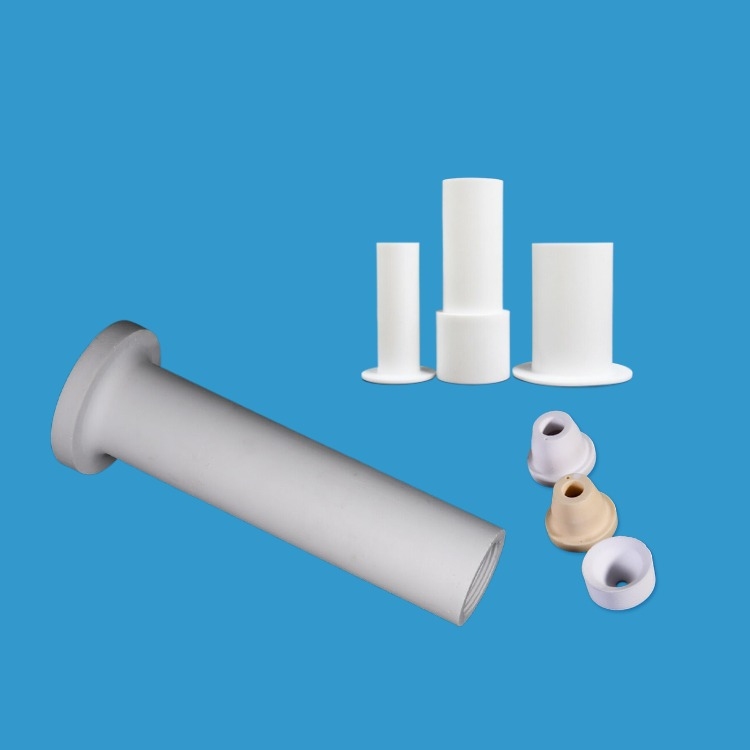

Ceramic linear bushing zirconia alumina ceramic liner sleeves

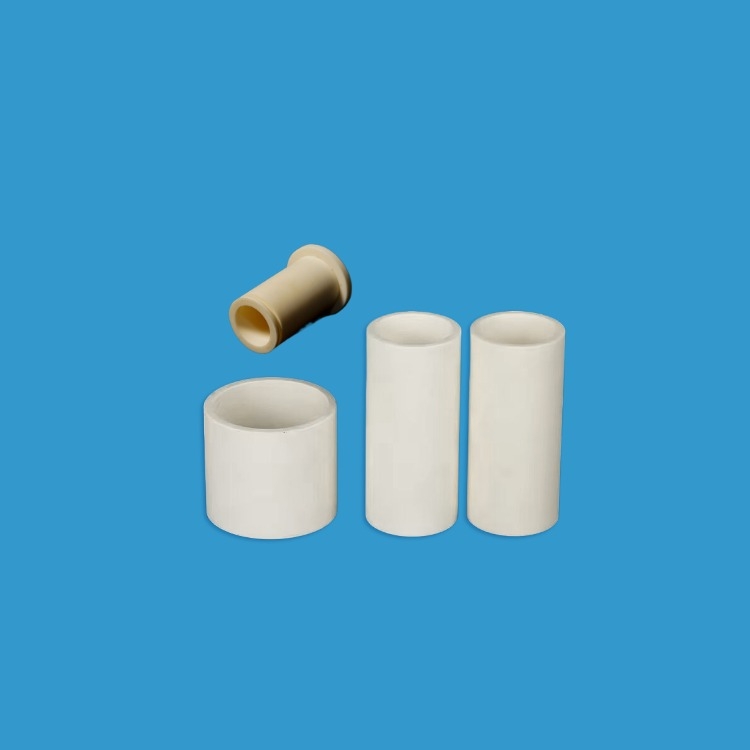

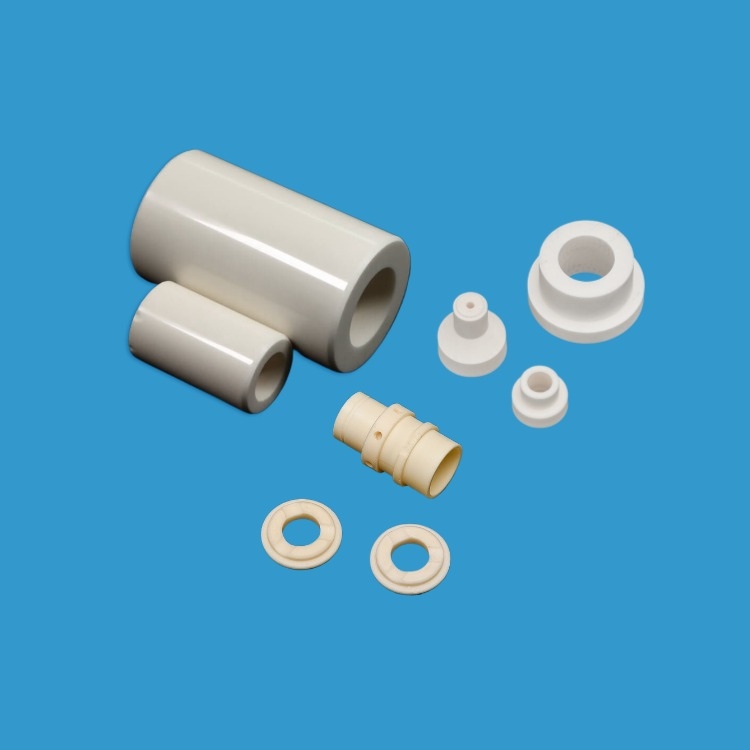

Ceramic materials are available:Zirconia, Alumina, Silicon nitride and machinable ceramic...etc

General sizes:ID 6 to 150mm; OD 10 to 180mm

Cylindricity: up to 0.004mm

Concentricity: up to 0.003mm

Features:wear resistance and friction resistance...

Customized:Can be custom for special sizes and shapes

Delivery times:2 -25 days(depends on the quantity)

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic linear bushing is a kind of parts or components used in machinery, industry and other fields. Ceramic linear bushing is an auxiliary component, mainly used to protect and support the main equipment or components, reduce wear and friction, improve the service life and performance of the equipment.

Ceramic linear bushing is usually a cylindrical part that is placed on the outside of other parts, which can be made of different ceramic materials. The main function of the ceramic linear bushing bushing is to provide additional support and protection, especially in the key parts of the equipment, to reduce wear and friction of the components.

The sizes of ceramic linear bushing

Inside diameter (d) : generally ranging from 6 mm to 150 mm.

Outer diameter (D) : generally from 10 mm to 180 mm.

Length (L) : Generally ranging from 10 mm to 150 mm.

The role of ceramic linear bushing

In mechanical equipment, ceramic linear bushing has a variety of important roles. First, it can act as a buffer, absorbing vibration and shock when the equipment is running. Secondly, because the ceramic linear bushing is usually made of ceramic materials with better wear resistance, the ceramic linear bushing can extend the service life of the equipment. In addition, the ceramic linear bushing can also improve the tightness of the equipment to prevent the leakage of lubricating oil or other liquids.

ceramic linear bushing is an important mechanical part, which plays a key role in protecting equipment, reducing wear and improving performance. By understanding and correctly using bushings, the working efficiency and life of mechanical equipment can be effectively improved.

Type of ceramic linear bushing

When the ceramic linner bushings are designed with flanges, they can handle combined loads. ceramic linear bushing bushings can be threaded on internal or external surfaces to accommodate various assembly conditions. In addition to different types, ceramic linear bushing with different ceramic material compositions are also available. The material composition of the bushing in the ceramic helps it to withstand various conditions in the operating environment, such as corrosion, high temperature, high pressure and shock.

The role of ceramic linear bushing is used outside the mechanical parts to seal and wear protection accessories, which refers to the ring sleeve that plays the role of the washer.

The role of the bushing in the ceramic has high flexibility and a variety of functions. A casing is a part of a protective device. The use of casing can reduce the wear, vibration and noise of the equipment, and has the effect of anti-corrosion. The use of ceramic bushings can also facilitate the maintenance of mechanical equipment and simplify the structure and manufacturing process of the equipment.

Selection factors for the role of the ceramic linear bushing:

Ceramic linear bushing has a wide range of applications and many kinds. Under different working conditions, it is necessary to choose the appropriate ceramic liner. When selecting the role of the ceramic linear bushing, the main considerations are pressure, speed, pressure-speed product and the load characteristics that the bushing needs to bear. In addition, whether the role of the ceramic linear bushing lubrication also determines its use effect and service life.

ceramic linear bushing sizes chart

Inside diameter: | Outside diameter: | length: |

3mm | 4-3/5" | 2-1/16" |

5mm | 5mm | 6mm |

6mm | 6.8mm | 7mm |

7mm | 8mm | 10mm |

8mm | 10mm | 12mm |

10mm | 11mm | 15mm |

12mm | 12mm | 16mm |

14mm | 13mm | 20mm |

15mm | 14mm | 21.5mm |

16mm | 16mm | 22mm |

17mm | 17mm | 23mm |

18mm | 18mm | 24.5mm |

20mm | 19mm | 25mm |

22mm | 20mm | 26mm |

24mm | 22mm | 28mm |

25mm | 23mm | 30mm |

30mm | 24mm | 31mm |

32mm | 25mm | 35mm |

35mm | 26mm | 39mm |

40mm | 27mm | 40mm |

44.933mm | 28mm | 42mm |

45mm | 30mm | 45mm |

50mm | 32mm | 49mm |

50.8mm | 33mm | 50mm |

52mm | 34mm | 60mm |

55mm | 35mm | 64mm |

57.15mm | 37mm | 70mm |

59.919mm | 38mm | 74mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.