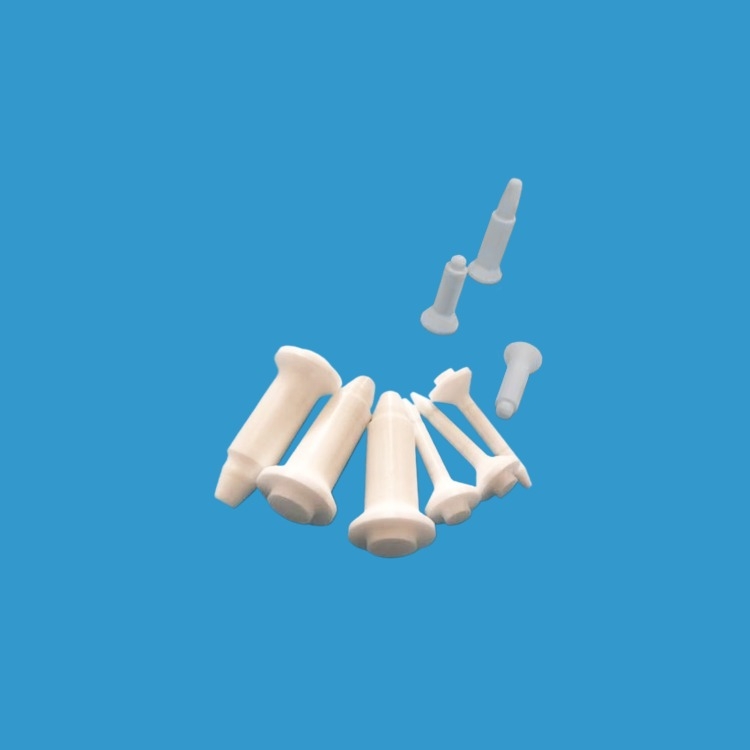

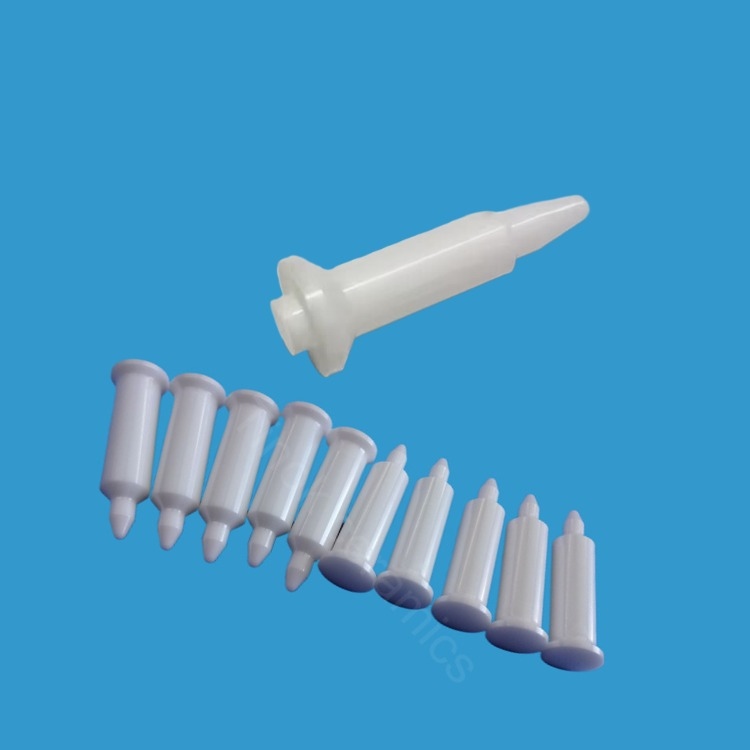

Ceramic locating pin high hardness ceramic location dowel pin zro2 ceramic pin

Ceramic materials are available:ZrO2,Si3N4,Ceramic ...etc

General diameter sizes:M4,M5,M6,M8,M10,M12

Precision:Ra 0.1um

Flexural strength:470Mpa

Feature :Wear Resistance, Insulation

Sample:Available

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Definition of ceramic locating pin

A ceramic locating pin also called a guide pin or locating pin, is a mechanical part used to guide and locating the workpiece during the assembly process so that it enters the corresponding position correctly and accurately. Ceramic locating pin are usually made of high-strength ceramics, have high wear resistance and hardness, and can withstand high-strength friction and impact.

Feature of ceramic locating pin

1.Excellent insulation

2. High Mechanical Strength

3. Outstanding Electrical and Electronic Properties

4. Wear Resistance

5. Extreme Temperature Stability

6. Resistant to Corrosion and Chemical Attack

The use of ceramic locating pin

Ceramic locating pin are generally used for parts locat positioning in automated or mechanized assembly processes to ensure the correctness and accuracy of parts in the assembly process.

Ceramic locating pin are widely used in automotive, electronics, mechanical engineering and other fields, which can improve assembly efficiency and quality, and reduce process loss and scrap rate.

The difference between ceramic locating pin and ceramic positioning parts

Both ceramic locating pin and positioning parts are positioning elements used in part assembly, but their roles and uses are different. Positioning parts are usually used to determine the position of the part, while the ceramic locating pin is mainly used to locating and position the part into the correct position. The ceramic locating pin is usually fixed on the assembly die or fixture to guide the part into the correct position, and the positioning part is directly used as a local positioning when the part is assembled.

The role of ceramic locating pin

The role of the ceramic locating pin mainly has two aspects: one is to guide the parts into the correct position to ensure the accuracy and consistency of the assembly process; The second is to prevent the skew, dislocation and offset of parts in the assembly process, and reduce the scrap rate and process loss. Through the use of ceramic locating pin, it is possible to ensure the correct assembly of parts, improve assembly efficiency and assembly quality.

Sizes of ceramic locating pin

Diameter:4mm-18mm,or Customized

Length:5mm-35mm,or Customized

Ceramic Locating Pin size table

Outer Diameter | Length |

(mm) | (mm) |

2 | 5-20 |

3 | 10-30 |

4 | 10-40 |

5 | 10-50 |

6 | 10-60 |

8 | 20-70 |

10 | 20-80 |

12 | 20-90 |

14 | 30-100 |

16 | 40-100 |

18 | 50-100 |

20 | 50-100 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.