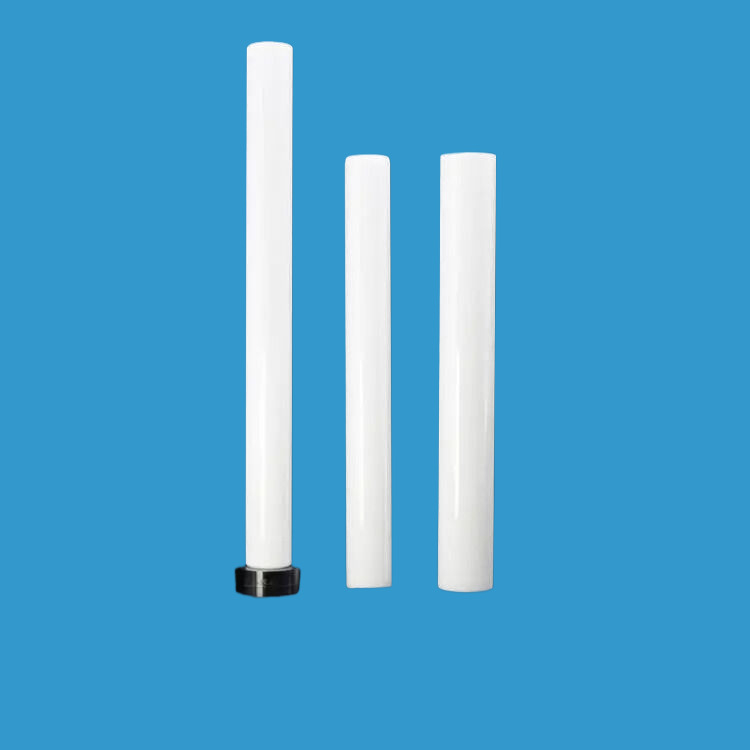

Ceramic piston rod Al2O3 alumina ZrO2 zirconia ceramic piston rod

Ceramic materials are available:Zirconia ceramics(ZrO2),Alumina ceramic (Al2O3 purity 95% to 99.99%)

General sizes:Length max up to 350mm

Surface finish: RA0.025

High hardness:15 to 19 GPa

tolerance: 0.001mm... etc

Features:High hardness and wear resistance...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Compared with metal piston rod, precision ceramic piston rod has obvious differences in wear resistance, corrosion resistance, weight, temperature stability and dimensional stability.

As a kind of high performance material, ceramic piston rod has been widely used in industrial field. Its high hardness, high wear resistance, high corrosion resistance and high temperature resistance make it an ideal choice.

Compared with metal piston rod, precision ceramic piston rod has obvious differences in wear resistance, corrosion resistance, weight, temperature stability and dimensional stability.

In the field of industrial machinery, ceramic piston rods can withstand high-speed and high-load working environments, improving the efficiency and stability of mechanical equipment. At the same time, its wear-resistant characteristics also help to extend the service life of mechanical equipment.

Precision ceramic piston rods have excellent wear resistance, corrosion resistance, light weight, high strength, good temperature stability and dimensional stability, making them the material of choice in many demanding engineering fields. Compared with metal piston rods, precision ceramic piston rods show better performance in many aspects, but in some special application scenarios, it is still necessary to choose according to specific needs.

Performance of ceramic piston rod

1. High hardness and wear resistance: ceramic piston rod has very high hardness and excellent wear resistance, so that it can withstand frequent wear and impact in the dispenser and maintain long-term stable operation.

2. Low friction coefficient: ceramic piston rod has a low friction coefficient, so that it can reduce energy loss in the dispenser and improve equipment efficiency.

3. High strength and rigidity: ceramic piston rod has high strength and rigidity, so that it can withstand a certain load in the dispensing machine and maintain good mechanical properties.

4. Chemical resistance: The ceramic piston rod has good chemical resistance, so that it can adapt to various chemical environments in the dispensing machine to ensure the stable operation of the equipment.

Application of ceramic piston rod in dispensing machine

1. Dispensing head assembly: Ceramic piston rod can be used to manufacture dispensing head assembly, its high hardness and wear resistance help to improve the accuracy and stability of the high point.

2. Pressure regulating parts: Ceramic piston rods can be used to manufacture pressure regulating parts, and their low friction coefficient and high temperature resistance help to improve the performance and life of the regulating parts.

3. Seals: Ceramic piston rods can be used to manufacture seals, and their chemical resistance and low coefficient of friction help to improve the performance and stability of seals.

Ceramic piston rod parameter

| length(mm) | diameter(mm) |

| 137 | 63 |

| 145 | 30 |

| 112 | 28 |

| 81 | 29 |

| 90 | 40 |

| 85 | 41 |

| 103 | 69 |

| 147 | 30 |

| 96 | 26 |

| 94 | 69 |

| 98 | 35 |

| 122 | 55 |

| 130 | 64 |

| 101 | 30 |

| 146 | 51 |

| 153 | 47 |

| 104 | 36 |

| 117 | 21 |

| 102 | 26 |

| 108 | 38 |

| 137 | 40 |

| 109 | 63 |

| 122 | 28 |

| 144 | 44 |

| 105 | 51 |

| 113 | 29 |

| 110 | 25 |

| 88 | 46 |

| 151 | 25 |

| 156 | 66 |

| 121 | 56 |

| 100 | 30 |

| 115 | 50 |

| 148 | 23 |

| 136 | 68 |

| 138 | 49 |

| 84 | 64 |

| 95 | 46 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.