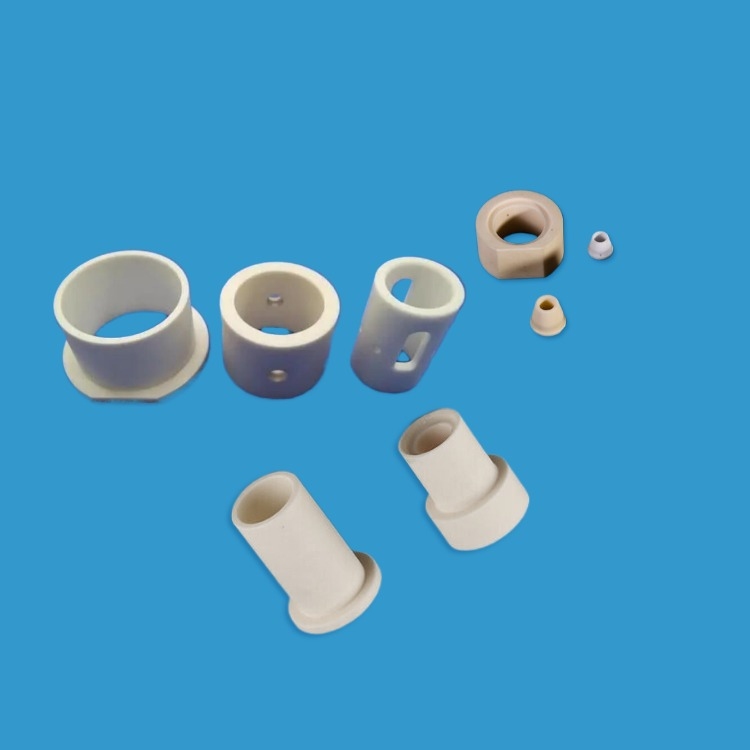

Ceramic shoulder bushing hardness strength wear resistant ceramic flanged bushings

Ceramic materials are available:Zirconia (ZrO2) ,Alumina (Al2O3) 95% to 99.99% , Silicon Carbide ,Silicon Nitride...etc

General sizes:Inside diameter (d) ranging from 6 mm to 150 mm.

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Excellent chemical resistance / Wear resistance / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic shoulder bushing refers to a bushing with a shoulder flange outside, that is a shoulder bushing.

A ceramic shoulder bushing is a round or square ceramic shoulder ring with fixed bolt holes for attaching to other equipment or structures. It is usually used to support rotating parts such as bearings, shafts, and gears to provide fixed support points.

The ceramic bushing is a ring part placed inside the ceramic shoulder flange, with a low coefficient of friction and good self-lubricating properties of the material. The role of the ceramic shoulder bushing is to reduce friction and wear while providing smoother movement. Ceramic shoulder bushings can make the work of mechanical equipment more smooth and efficient.

Standard ceramic shoulder bushing assemblies are commonly used in a variety of mechanical equipment, such as pumps, fans, transmissions, etc., to provide reliable support and smooth movement. Its ceramic shoulder bushing can work without the need for additional lubricants, and has a long service life and low maintenance costs.

Therefore, when selecting a standard ceramic shoulder bushing assembly suitable for a specific application, we should consider working conditions, load requirements, environmental factors and other factors, and correctly install and maintain according to actual needs.

Ceramic shoulder bushing function:

1, in terms of ceramic shoulder flange, generally play a role in positioning, not easy to fall off, sliding;

2, bushing: shoulder bushing mainly plays a protective role, protecting the shaft and the matrix are not directly worn, the general ceramic shoulder bushing material is slightly soft, and the shaft is worn, the bushing is worn, and it can be easily replaced. If the bushing is not used, the parts are replaced after wear. It plays a vital role in the normal application and maintenance of mechanical equipment.

Overview of ceramic shoulder bushing

a. Low maintenance frequency.

b. More able to withstand heavy loads than ceramic rolling bearings.

c. Ceramic shoulder bushing can also be used under harsh temperature conditions of "high temperature" and "low temperature".

d. Compared with ceramic rolling bearings, Ceramic shoulder bushing is thin and space-saving.

e. Ceramic shoulder bushing can be used for linear and rotational motion.

f. The structure is simple, compact, convenient design, so it is widely used in machine tools, textile machinery, light industry machinery, printing machinery, mechatronics assembly. Models in stock can be shipped as soon as the same day.

Ceramic shoulder bushing features

a. High temperature resistance.

b. Excellent chemical resistance.

c. Strong impact resistance.

d. Most suitable for use under heavy load and low speed operation conditions. Excellent wear resistance in parts that are difficult to form oil film, such as reciprocating movement and frequent starting and stopping.

e. Thin wall type, support non-standard customization.

ID Range | Outside Diameter | Length |

4.01-5.00mm | 8mm | 8mm |

8.032-8.023mm | 12mm | |

16mm | ||

5.01-6.00mm | 10mm | 10mm |

10.032-10.023mm | 16mm | |

20mm | ||

15.01-18.00mm | 26mm | 16mm |

26.048-26.035mm | 28mm | |

36mm | ||

48.01-55.00mm | 70mm | 30mm |

70.078-62.059mm | 56mm | |

67mm | ||

55.01-63.00mm | 78mm | 35mm |

78.078-78.059mm | 67mm | |

78mm | ||

78.01-85.00mm | 105mm | 40mm |

105.101-105.079mm | 78mm | |

105mm |

Us supports customization of different types ceramic shoulder bushing

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.