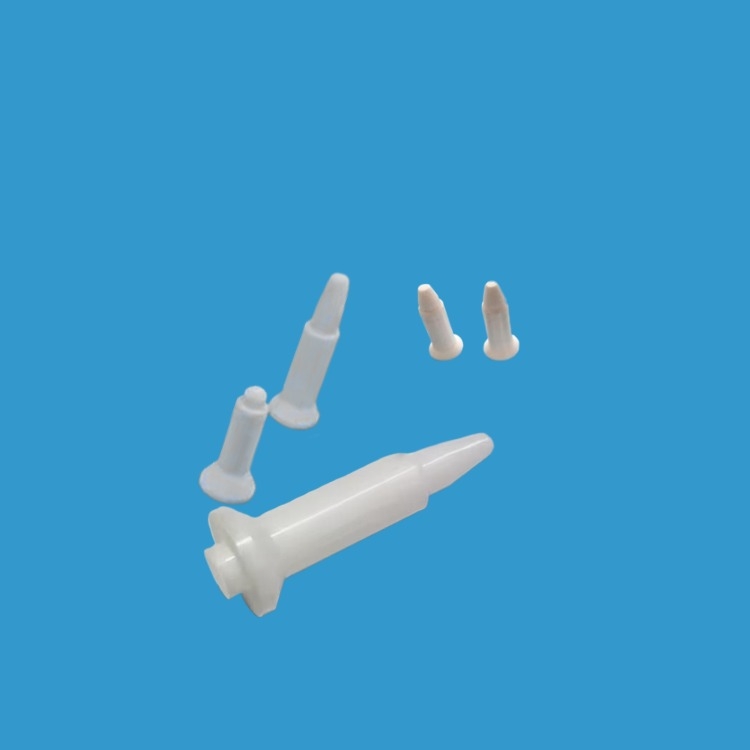

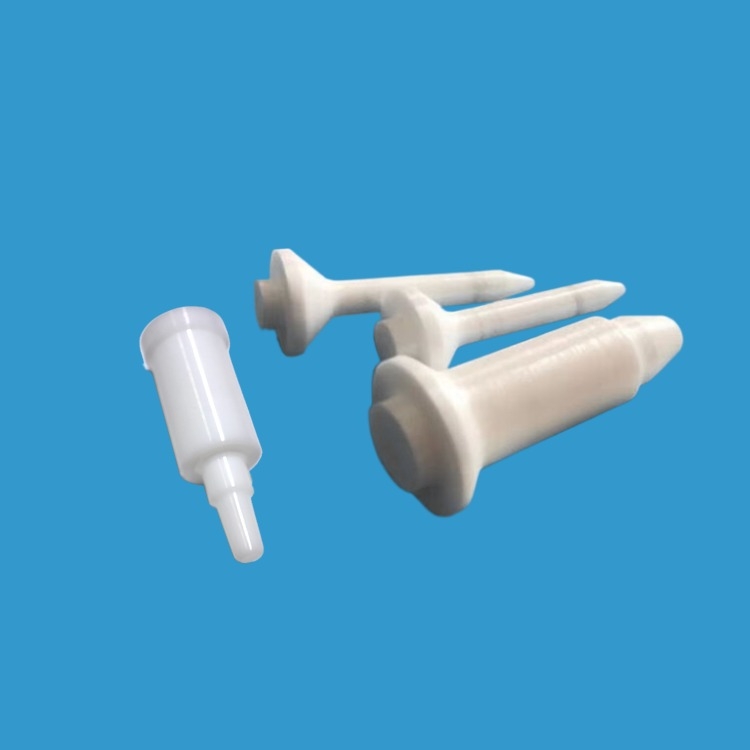

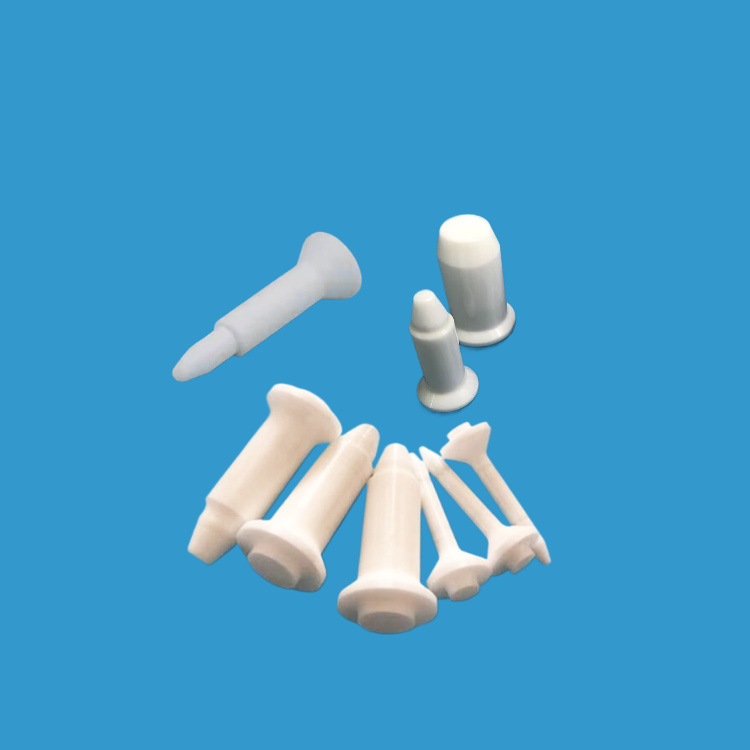

Ceramic welding pin high wear resistance and strength welding pin

Ceramic materials are available:AL2O3,ZrO2,Si3N4,Ceramic ...etc

General diameter sizes:M4,M5,M6,M8,M10,M12

Thermal conductivity:21.5W/(m·k)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:high hardness, high wear resistance, good insulation...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Definition of ceramic welding pin:

The ceramic welding pin is a component used for positioning and fixing the welding workpiece, which is suitable for welding parts that need to be disassembled and assembled frequently. The use of soldered ceramic welding pin can improve the accuracy and production efficiency of the workpiece, and ceramic welding pin can be used multiple times or cross-used between different workpieces. In machinery manufacturing, automobile manufacturing and other industries, welding welding pins have been widely used.

ceramic welding pin for welding fixture is a kind of mechanical part, ceramic welding pin mainly used for positioning and fixing fixture and workpiece. In the welding fixture, the ceramic welding pin is generally made of cold-drawn steel, which has high wear resistance and strength and can meet the requirements of high strength of the fixture.

Ceramic welding pin advantage:

Very hard, and highly resistant to abrasion. -Heat resistance

Highly resistant to heat, and usable at high temperature. - Electrical isolation

High in dielectric resistance at high temperature and dielectric strength under high pressure.

Cost-effective

No spatter adhesion, and durable.

The ceramic welding pin used for welding jig of industrial accessories is characterized by its high precision, good stability and long life. In the welding process, if the positioning is accurate, the quality and accuracy of the welding parts can be guaranteed. At the same time, welding pins also help improve production efficiency and reduce waste.

The type of ceramic welding pin

According to the different fixture design and application needs, the shape, size and material of the ceramic welding pin are different, such as the right Angle welding pin, anti-runout welding pin, flange welding pin and so on. At the same time, the welding pins for welding fixtures also have different standards, such as GB, JIS, DIN, ISO and other international standards.

Welding jig welding pin role

Welding fixture welding pin refers to the fixed part used for clamping and positioning, usually used to clamp the workpiece for processing, assembly or detection. Its main function is to ensure the accuracy and quality of the workpiece being machined. In the welding process, the welding pin of the welding fixture has obvious advantages, which can improve the accuracy and efficiency of welding, and ensure the quality of the welding joint.

The classification of welding fixture ceramic welding pin

According to different application scenarios, welding fixture welding pins can be divided into the following types:

1. Manual fixture ceramic welding pin

Manual fixture welding pins are usually used for small, lightweight machining workpieces, but can also be used for simple and quick positioning. This kind of fixture welding pin has the characteristics of simple use and flexible operation, but its positioning accuracy is not as good as other types of welding pins

2. Pneumatic fixture welding pin

The ceramic welding pin of the pneumatic fixture is a tool for clamping and positioning through the piston of the cylinder block driven by the air. This ceramic welding pin can achieve fast and accurate operation, suitable for frequent positioning situations, such as automated welding production lines.

Hydraulic fixture ceramic welding pin

The ceramic welding pin of hydraulic fixture is a tool to complete clamping and positioning by hydraulic drive, which has the characteristics of simple operation and high precision. This kind of welding pin is mainly used in large and heavy machining workpieces.

Mechanical fixture ceramic welding pin

The ceramic welding pin welding pin of the mechanical fixture is a tool that controls the action of the piston through the transmission mechanism to achieve clamping and positioning. This ceramic welding pin welding pin is mainly used in the need for precision machining of the workpiece, such as high-precision welding.

Ceramic welding pin use precautions

1. When using the ceramic welding pin of the welding fixture, pay attention to the matching of parameters such as model, specification and durability to ensure the stability and reliability of the use effect.

2 Fixture ceramic welding pin in use to often check its surface finish and whether there is damage, to avoid problems in use.

3. Pay attention to the use of appropriate methods during the processing of the fixture welding pin to avoid damaging the parts of the welding fixture welding pin.

4. The fixture ceramic welding pin shall be cleaned and maintained in time after processing to ensure that it can maintain a stable use effect.

Ceramic welding pin size table

Outer Diameter | Length |

(mm) | (mm) |

3.18 | 20 |

3.48 | 34 |

2.1 | 53 |

1.2 | 75 |

3.2 | 90 |

4 | 130 |

6 | 110 |

4.78 | 95 |

5 | 84 |

5.38 | 340 |

6.35 | 210 |

6.71 | 110 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.