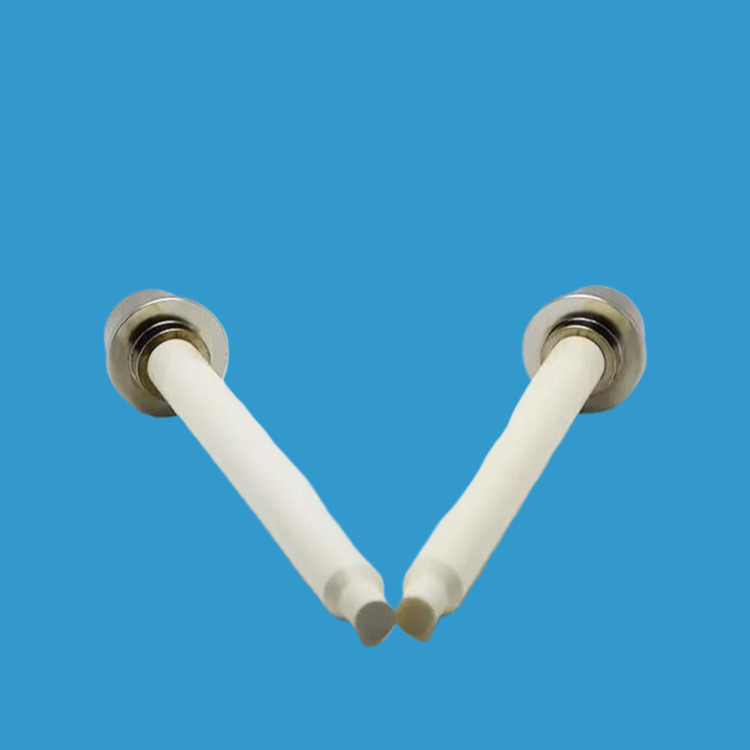

General pump ceramic plunger pump ceramic part plunger piston rod tubes

Ceramic materials are available:Zirconia ceramics(ZrO2),95% to 99.99%purity alumina

General sizes:Length max up to 130mm

Outer Diameter:140mm

Max Pressure:20MPa

tolerance: 0.001mm... etc

Features:high hardness and corrosion resistance...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

General pump ceramic plunger adopts modern engineering ceramic material superhard wear resistance for general pump, ceramic plunger can be assembled by ceramic metallization bonding, welding, Mosaic and socket technology.

General pump ceramic plunger is an ideal substitute for similar metal pumps, and has been widely used in medical equipment, environmental engineering, petroleum, chemical and other industries.

It has the following characteristics:

(1) Ceramic plunger for general pump using high-performance technology ceramic material, with high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Ensure reliable material performance.

(2) The micro-porous structure obtained by the unique processing means of the ceramic plunger working face has a self-lubricating effect, which changes the sliding friction of the traditional plunger pump And the lubrication mechanism.

(3) The surface of the inner cavity adopts a fluid structure, without dead corners and grooves. The surface of the inner cavity and the surface of the plunger are processed by advanced high-precision internal and external cylindrical grinding machine

To mirror, external surface vibration polishing, convenient cleaning, disinfection.

(4) The pump body structure is finely sealed with the product structure for easy disassembly.

(5) This kind of product has been corrosion resistance, acid and alkali resistance safety performance test, its indicators have reached the level of similar foreign products.

General pump ceramic plunger have excellent corrosion resistance. In some highly corrosive environments, such as the chemical industry and Marine engineering fields, ceramic plunger rods can resist the erosion of acid and alkali, salt spray and other corrosive substances, and maintain stable performance and long service life.

The general pump ceramic plunger also has a high temperature resistance. At high temperatures, the ceramic plunger rod can maintain stable physical and chemical properties without deformation, softening and aging. This makes the ceramic plunger rod widely used in high temperature furnace, heat treatment equipment and aerospace and other fields.

Some our general pump ceramic plunger parameter:

| length(mm) | diameter(mm) |

| 95 | 54 |

| 70 | 31 |

| 136 | 31 |

| 128 | 50 |

| 86 | 35 |

| 56 | 43 |

| 53 | 48 |

| 66 | 32 |

| 82 | 57 |

| 107 | 55 |

| 121 | 49 |

| 75 | 52 |

| 96 | 57 |

| 109 | 51 |

| 138 | 44 |

| 58 | 34 |

| 98 | 49 |

| 62 | 36 |

| 70 | 32 |

| 49 | 60 |

| 143 | 50 |

| 56 | 49 |

| 123 | 53 |

| 137 | 47 |

| 96 | 50 |

| 103 | 39 |

| 124 | 58 |

| 103 | 31 |

| 94 | 56 |

| 45 | 40 |

| 134 | 54 |

| 66 | 58 |

| 100 | 46 |

| 104 | 48 |

| 99 | 51 |

| 61 | 35 |

| 106 | 49 |

| 85 | 39 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.