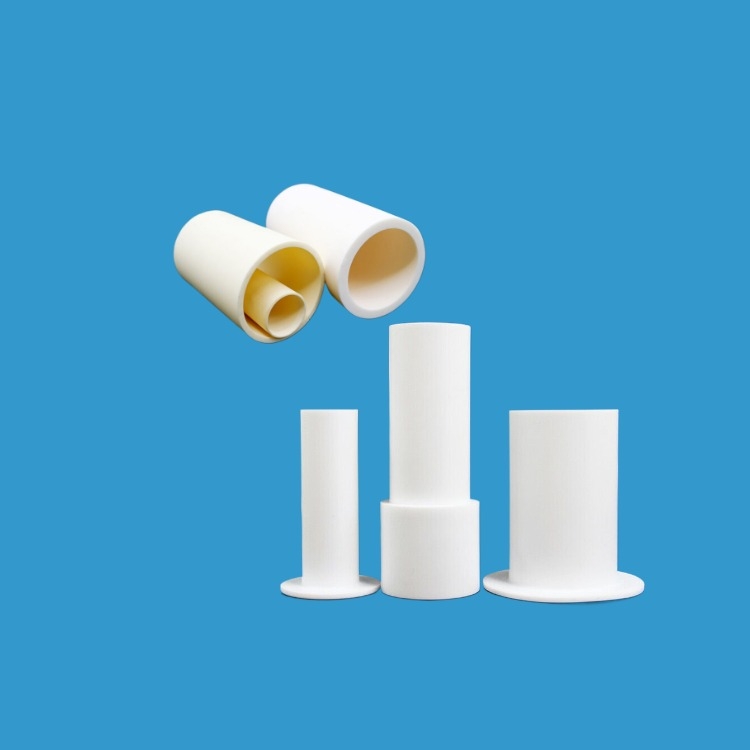

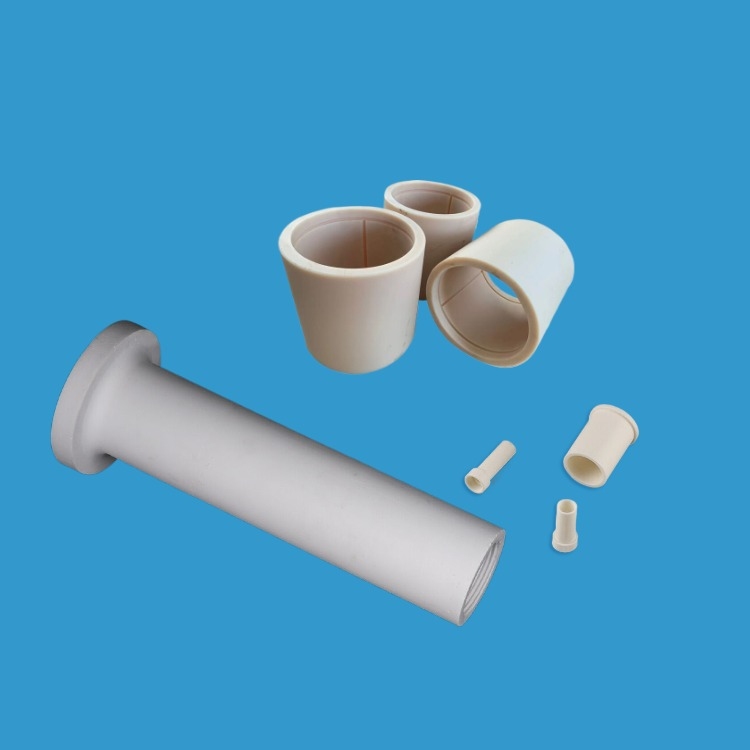

High temperature ceramic bushing high heat resistant ceramic sleeve bushings

Ceramic materials are available:Zirconia (ZrO2) ,Alumina (Al2O3) 95% to 99.99% , Silicon Carbide ,Silicon Nitride...etc

General sizes:Outer diameter (D1) : generally from 10 mm to 180 mm.

Delivery times:2 -20 days(depends on the quantity)

Concentricity: up to 0.003; Inner hole: minimum 0.12x3mm;

Features:high temperature resistant...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

High temperature resistant ceramic bushing has different withstand capacities at high temperatures. Ordinary alumina or zirconia ceramics can withstand high temperatures above 1000 ° C when heated, while the peak temperature of advanced ceramics such as silicon carbide ceramics and silicon nitride ceramics can reach more than 1500 ° C.

High temperature resistant ceramic bushing can withstand high temperature environment above 1000 degrees Celsius.

high temperature resistant ceramic bushing is a special mechanical component designed for stable and reliable performance in high temperature environments. This type of ceramic bushing usually has high temperature resistance and can work for a long time under high temperature conditions without performance degradation or damage. The construction and material selection of high temperature resistant ceramic bushing is the key to its ability to withstand high temperatures, and is usually made of high temperature resistant materials, such as certain metal alloys, ceramics or other high temperature resistant materials. These materials have good thermal stability and oxidation resistance, and can keep their physical and chemical properties unchanged in high temperature environments, thus ensuring the normal operation and safe use of mechanical equipment.

Common high temperature resistant ceramic bushing

1. Alumina ceramic bushing

Alumina ceramic is a kind of ceramic material with high compressive strength and hardness, while resisting corrosion, wear and high temperature. It can withstand high temperatures of up to 1600 ° C, so it is widely used in high temperature environments, such as high temperature stoves, heat treatment furnaces, aviation and aerospace fields.

2. Zirconia ceramic bushing

Zirconia ceramics are also an excellent high temperature resistant material, which has high chemical stability and thermal stability, and can withstand high temperatures of up to 2700℃. Zirconia ceramics are used in a wide range of applications, such as spark plugs, engine turbines and so on.

3. Silicon carbide ceramic bushing

Silicon carbide ceramics is a new kind of high hardness, high strength and high temperature resistance material, which can withstand high temperatures of up to 1800℃. Silicon carbide ceramics have good wear resistance, corrosion resistance and high temperature resistance, suitable for high temperature furnace protection tubes, microwave kilns, solar cells and so on.

High temperature resistant ceramic bushings have a wide range of applications, including but not limited to industrial equipment, aerospace, automotive manufacturing and other fields. In these fields, equipment often needs to operate under high temperature conditions, so high-temperature ceramic bushings become indispensable components. For example, in automotive engines, high-temperature resistant ceramic bushings can protect key components of the engine and prevent them from being damaged by high temperatures, thereby improving the performance and life of the engine.

The main application areas of high temperature resistant ceramic bushing

1. Aerospace field: high-temperature ceramics can be used to manufacture engine nozzles, rocket engines and other high-temperature components.

2. Energy field: high temperature resistant ceramics can be used as components of nuclear power plants, thermal power plants and other power stations.

3. Metallurgical field: high temperature resistant ceramics can be used for the manufacture of high temperature reactors.

4. Mechanical field: high-temperature ceramics can be used to manufacture high-speed, high-load bearings, seals and other high-temperature components.

The importance of high temperature resistant ceramic bushing

First of all, high temperature resistant ceramic bushing has excellent high temperature resistance. In many industrial production, equipment needs to work in a high temperature environment, and traditional metal materials are prone to thermal expansion, thermal deformation and other problems in this case, seriously affecting the normal operation of equipment and production efficiency. And high temperature resistant ceramic bushing can maintain stable performance in high temperature environment, effectively solve this problem.

Secondly, high temperature resistant ceramic bushing has excellent wear resistance and corrosion resistance. In many industrial processes, equipment needs to withstand prolonged friction and corrosion, which puts high demands on the durability of equipment. high temperature resistant ceramic bushings can effectively increase the service life of the equipment through its unique chemical stability and wear resistance.

Finally, high temperature resistant ceramic bushing has good mechanical strength. In many industrial production, equipment needs to withstand greater pressure and impact, which puts high requirements on the mechanical strength of equipment. The high temperature resistant ceramic bushing can effectively protect the internal structure of the equipment and prevent damage to the equipment through its high strength mechanical properties.

ID Range | Outside Diameter | Length |

1.81-2.60mm | 5mm | 6mm |

5.027-5.019mm | 9mm | |

10.01-12.00mm | 18mm | 12mm |

18.039-18.028mm | 20mm | |

25mm | ||

12.01-15.00mm | 22mm | 16mm |

22.048-22.035mm | 28mm | |

36mm | ||

18.01-22.00mm | 30mm | 20mm |

30.048-30.035mm | 36mm | |

45mm | ||

30.01-35.00mm | 48mm | 25mm |

48.059-48.043mm | 45mm | |

56mm |

Us supports customization of different types high temperature resistant ceramic bushing

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.