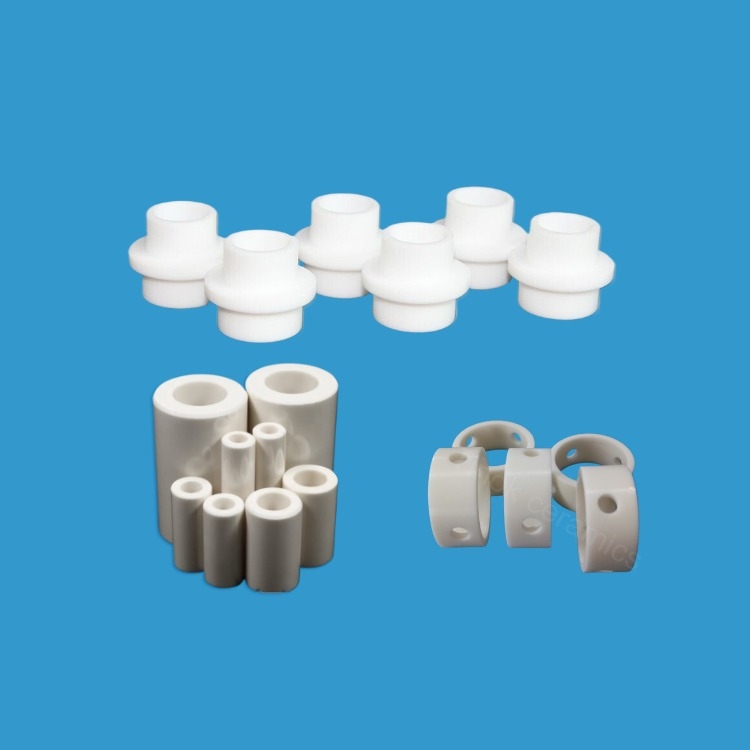

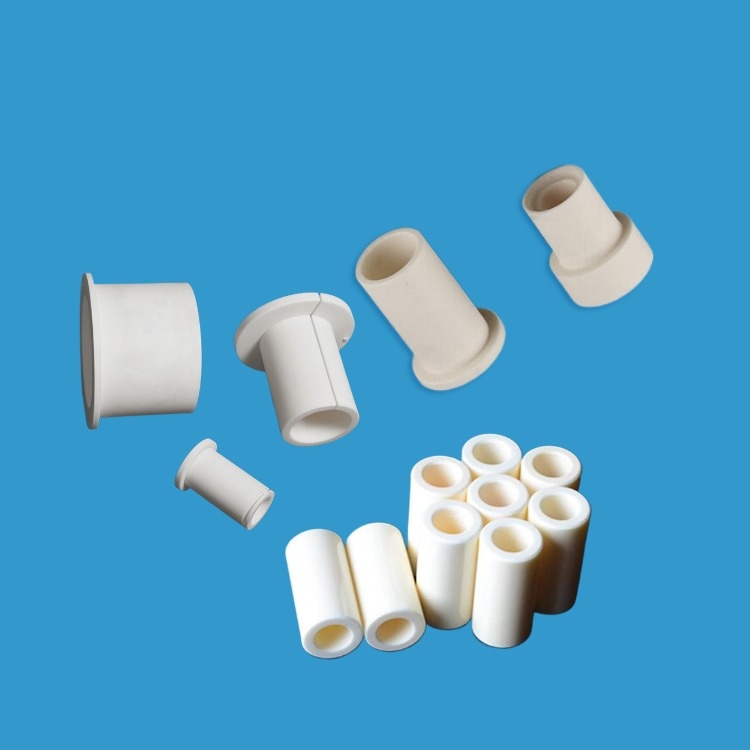

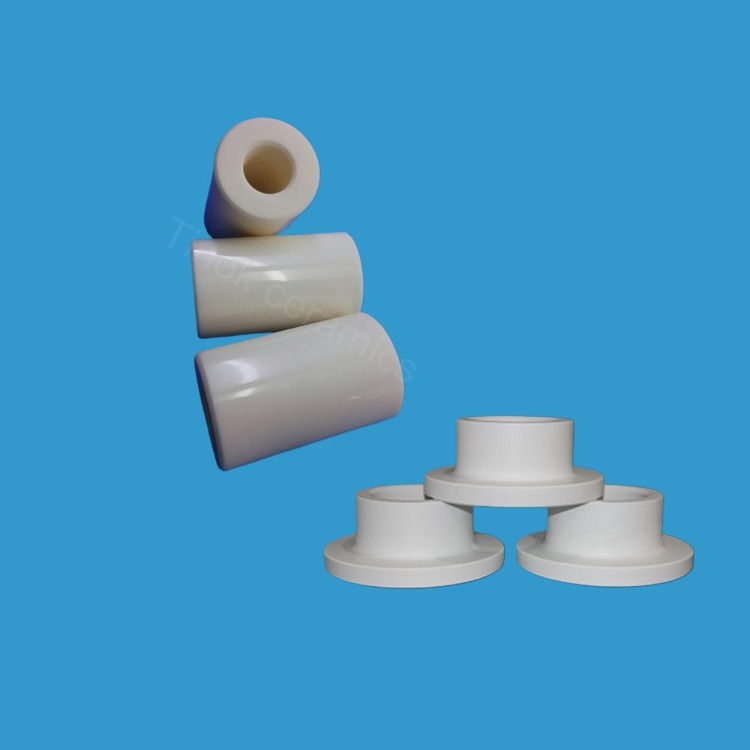

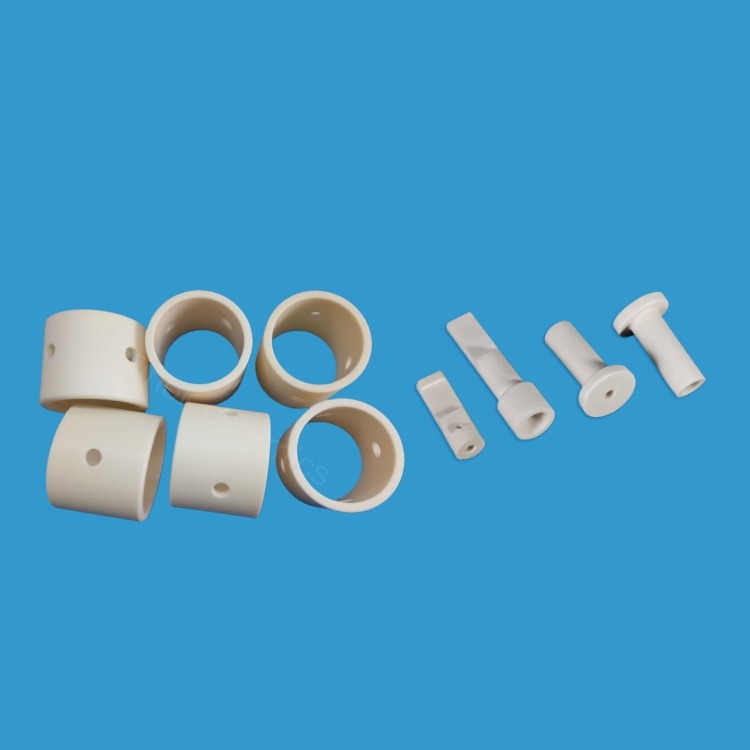

Threaded ceramic bushings high strength high precision surface smooth threaded ceramic tube bushing

Ceramic materials are available:Zirconia, Alumina, Silicon nitride and machinable ceramic...etc

General sizes:12 mm,18 mm,20 mm,15 mm,22 mm,25 mm,30 mm,34 mm

Cylindricity: up to 0.004mm

Thread: The minimum internal thread can be machined M2, the external thread is not limited.

Features:wear resistance and friction resistance...

Customized:Can be custom for special sizes and shapes

Delivery times:2 -25 days(depends on the quantity)

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

What is threaded ceramic bushing?

Threaded ceramic bushing is a commonly used mechanical part, which is a part that is fitted on the thread. Its interior is finely machined into a threaded shape, which can be matched with external threads to make the assembly more tight and stable. threaded ceramic bushing is usually used for fixing and connecting on mechanical shafts to improve the working efficiency and operational stability of mechanical equipment.

Thread ceramic bushing is a kind of high strength, high precision, surface smooth cold rolled diamond shaped stainless steel wire precisely formed spiral coil, for high precision internal and external thread concentric body, can form a standard thread, thread protection set can form a high precision internal thread in line with international standards, its various properties are better than the thread formed by tapping.

Classification of threaded ceramic bushings

According to different application scenarios and shape characteristics, threaded ceramic bushings can be divided into many types. Among the more common are the following:

1. Hexagonal thread ceramic bushing: mainly used to connect bolts and nuts, play a firm role.

2. Internal thread ceramic bushing: mainly used to repair and strengthen threaded holes.

3. Long thread ceramic bushing: mainly used to increase the depth and contact area of threaded connection.

4. Anti-loose thread ceramic bushing: mainly used to prevent thread loosening and small vibration.

Function of threaded ceramic bushing

1. Withstand and transmit force: threaded ceramic bushing can not only connect and fix mechanical parts, but also withstand and transmit force, so that mechanical equipment can work in an orderly manner.

2. Reduce wear: threaded ceramic bushing can effectively reduce the wear between mechanical parts, prevent the damage caused by long-term friction, and also protect the surface of the mechanical shaft from wear and corrosion.

3. Improve service life: The use of threaded ceramic bushing can greatly extend the service life of mechanical equipment, reduce the downtime caused by wear and damage to mechanical parts, and improve production efficiency and economic benefits.

Application of threaded ceramic bushing in mechanical design

1. Usually used for the connection and fixing of mechanical shafts, this connection method can reduce the gap between mechanical parts, make the assembly more tight and stable, and effectively prevent shaft jitter or thread loosening due to vibration and wear.

2. In the manufacture and repair of mechanical parts, threaded ceramic bushings can be used to repair the poor fit caused by thread wear and damage, and reduce the frequency of mechanical parts replacement.

3. In mechanical production, threaded ceramic bushings usually need to be used with other mechanical accessories, such as threaded rods, socket sleeves, etc., to meet the needs of different mechanical equipment.

Threaded ceramic bushing size charts

ID Range | Outside Diameter | Length |

3.31-4.00mm | 7mm | 8mm |

7.032-7.023mm | 12mm | |

16mm | ||

4.01-5.00mm | 8mm | 8mm |

8.032-8.023mm | 12mm | |

16mm | ||

26.01-30.00mm | 42mm | 25mm |

42.059-42.043mm | 45mm | |

56mm | ||

35.01-42.00mm | 55mm | 30mm |

55.072-55.053mm | 56mm | |

67mm | ||

42.01-48.00mm | 62mm | 30mm |

62.072-62.053mm | 56mm | |

67mm | ||

55.01-63.00mm | 78mm | 35mm |

78.078-78.059mm | 67mm | |

78mm | ||

85.01-95.00mm | 115mm | 45mm |

115.101-115.079mm | 89mm | |

112mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.