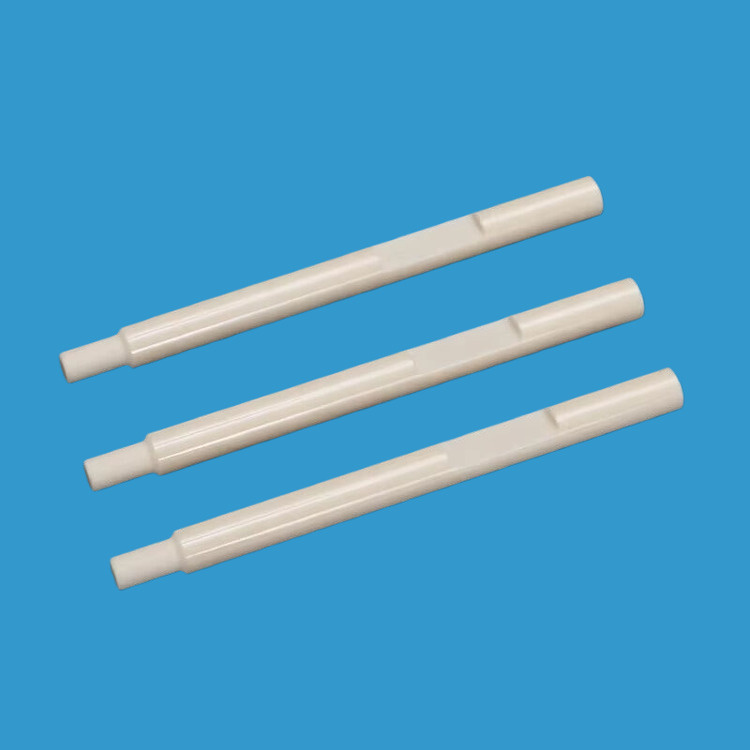

Water jet ceramic plunger high polished wearable waterjet parts ceramic plunger rod

Ceramic materials are available:alumina or zirconia ceramics

Tolerance: 0.01mm ~ 0.002mm

Length: 10mm~200mm

Surface roughness: RA0.2~RA0.05

Features:excellent resistance to wear, corrosion and high temperature stability.

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

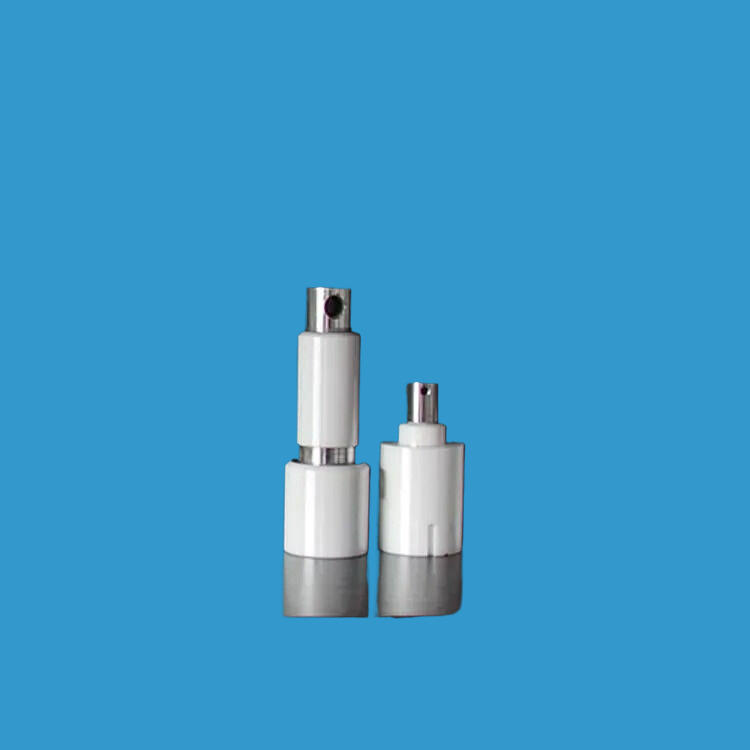

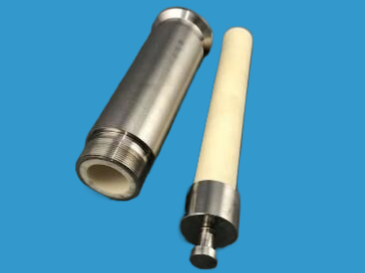

The water jet ceramic plunger is the key component of the supercharger, which forms a high-pressure jet by pressing water through the oil pump pressure. Ceramic material, wear resistance and corrosion resistance. It is necessary to check, clean and lubricate regularly to avoid impact overload. Ensure that the installation is accurate and the environment is dry. Professional maintenance ensures performance.

Water jet ceramic plunger basic definition and function

The water jet ceramic plunger is an important part of the water jet part supercharger, which is mainly used to squeeze water in the piston movement, and extrude the water in the high pressure cylinder through the oil pump pressure as the power to form a high pressure water jet. water jet ceramic plunger takes advantage of the characteristics of ceramic or other hard materials, as well as the characteristics of smooth surface, high strength extrusion of tap water, so that it forms high pressure water for cutting and other operations.

Water jet ceramic plunger material and characteristics

water jet ceramic plunger is usually made of high strength, high wear resistance, high corrosion resistance materials such as ceramics. Ceramic materials have the advantages of low heat, smooth surface and high hardness, which make the water jet ceramic plunger maintain stable and efficient performance under high pressure and high speed working environment.

Water jet ceramic plunger working principle

In the water jet part system, when the oil pump provides sufficient pressure, the piston rod will do reciprocating motion in the high pressure cylinder. One end of the piston rod is connected to the piston, and the other end is connected to the external mechanism in some way. With the movement of the piston, the piston rod will push the water in the high pressure cylinder to squeeze, thus forming a high pressure water jet. This high pressure water jet has a strong cutting ability and can be used to cut materials of various hardness.

Water jet ceramic plunger maintenance

Regular inspection: The surface wear of the water jet ceramic plunger, the sealing performance and the tightness of the connecting parts should be checked regularly. If abnormal wear or seal is found, it should be repaired or replaced in time.Cleaning and lubrication: Keeping the water jet ceramic plunger clean and lubricated is essential for its proper operation. The dirt and impurities on the surface of the piston rod should be cleaned regularly, and the appropriate amount of lubricating oil should be applied to reduce friction and wear.

Avoid impact and overload: adverse factors such as impact or overload on the water jet ceramic plunger should be avoided during use so as not to damage its structure and performance.

Matters needing attention

Installation requirements: When installing the piston rod of the water jet part, it should be ensured that the coordination accuracy and sealing performance of the high pressure cylinder, piston and other components meet the requirements. At the same time, avoid damage or deformation during installation.

Use environment: The use environment of the water jet ceramic plunger should be kept dry and clean, and avoid long-term exposure to damp and corrosive environment.

Professional maintenance: If you encounter problems or failures that cannot be solved, you should contact professional maintenance personnel in time for repair or replacement.

Water jet part ceramic plunger rod size specification table is as follows:

1. Diameter: 6.35~ 312.5mm

2. Special shapes: flat, rectangular, triangle, pentagonal, hexagonal and other special shapes

3.Tolerance: 0.01mm ~ 0.002mm

4. Length: 10mm~200mm

5. Surface roughness: RA0.2~RA0.05

6. Compressive strength: 1500MPa or more

7. Density: 6.0~6.15g/cm3

8. Specific strength: 36000J/m3 or more

9. Coefficient of thermal expansion: 7.0×10^-6/K or more

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.