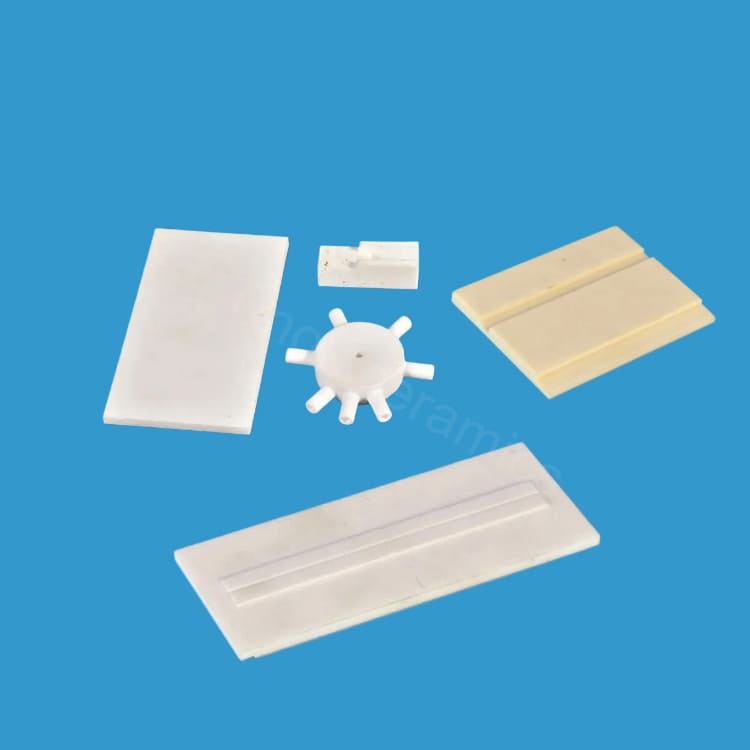

Zirconia ceramic plate high strength different size zirconia ceramic sheet

Ceramic materials are available:ZrO2 zirconia Ceramic ...etc

General diameter sizes:80*120*10mm;100*100*2mm;100*100*3mm;100*100*10mm

;135*200*1.5mm;135*200*2mm ;150*150*1mm

Roundness:0.002mm

Compressive Strength:55 Mpa

Feature :high density, high mechanical

Sample:Available

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Zirconia ceramic plate has the characteristics of high safety reliability, high density, high mechanical properties, high civilian and thermal load performance, low dielectric loss and so on. Zirconia ceramic plate is the most commonly used plate material in the electronics industry, because in mechanical, thermal and electrical properties compared to most other zirconia ceramics, high strength and chemical stability, and rich raw material sources, suitable for a variety of technical manufacturing and different shapes.

Use of zirconia ceramic plate:

1, according to its wear resistance characteristics, zirconia ceramic plate is generally used in the machinery manufacturing industry, used to replace metal wear-resistant parts, transmission structures and so on.

2, zirconia ceramic plate is a more important kind of engineering ceramics, mainly used to replace industrial steel products, iron products and copper products, the cost is much lower than metal products.

3, zirconia ceramic plate can also be used in electronics, electrical industry, with ceramics as the main material, combined with some other accessories, you can make flame retardant characteristics of zirconia ceramic plate, as well as antistatic, magnetic conductivity and so on, become a material that many industries are inseparable.

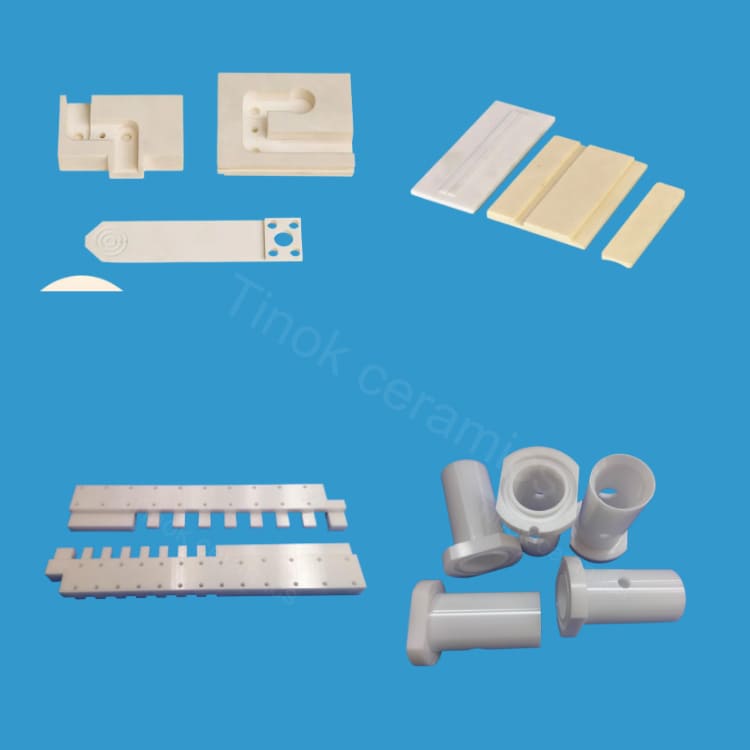

Characteristics of zirconia ceramic plate:

1, zirconia ceramic plate can replace the normal metal products of the device, then it must have high strength and high rigidity characteristics, so as to withstand the pressure of all kinds of metal devices, become their substitutes.

2, in addition to the characteristics of high stiffness and high strength, according to different production accessories, zirconia ceramic plate can also show other physical properties, such as heat resistance, flame retardant, barrier and so on.

Ceramic properties of zirconia ceramic plate

1. High toughness

2. High bending strength

3. High wear resistance

4. Excellent thermal insulation and Coefficient of thermal expansion similar to steel.

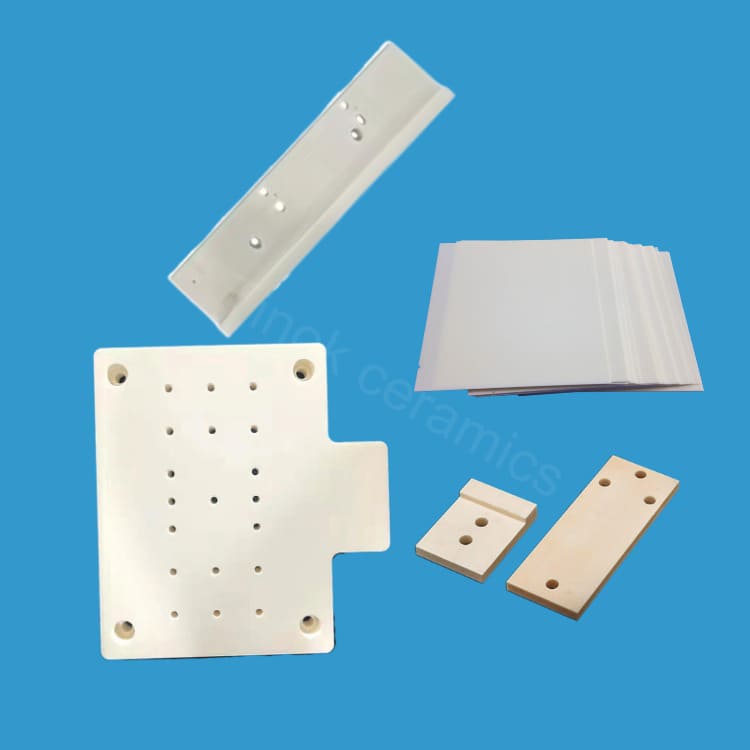

Forming methods of zirconia sheet

Extrusion, Dry pressed, Hot pressed, Ceramic Injection molding, ISO pressed

Surface treatment

External and internal surface to be polished, glazed or metalized

Secondary processing of zirconia sheet

CNC machining, lapping, threaded, drilling, grinding, precision laser cutting

Zirconia ceramic plate size charts:

Length | Width | Thickness |

80 | 80 | 2mm |

80 | 80 | 3mm |

80 | 80 | 5mm |

80 | 110 | 5mm |

80 | 120 | 8mm |

80 | 120 | 10mm |

80 | 120 | 20mm |

80 | 210 | 20mm |

100 | 100 | 2mm |

100 | 100 | 2.5mm |

100 | 100 | 3mm |

100 | 100 | 3.5mm |

100 | 100 | 4mm |

100 | 100 | 5mm |

100 | 100 | 10mm |

100 | 100 | 18mm |

100 | 100 | 20mm |

110 | 110 | 5mm |

110 | 110 | 8mm |

112 | 112 | 5mm |

120 | 120 | 0.25mm |

135 | 200 | 2mm |

139 | 189 | 1mm |

150 | 150 | 1mm |

150 | 150 | 1.5mm |

150 | 150 | 2mm |

150 | 150 | 3mm |

150 | 150 | 5mm |

150 | 150 | 40mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.