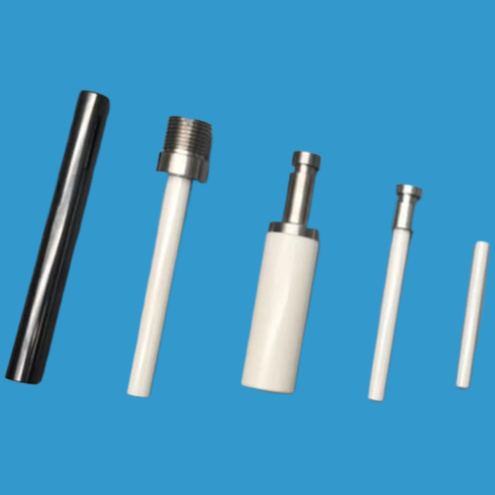

Zirconia ceramic plunger high hardness corrosion resistance ZrO2ceramic plunger

Ceramic materials are available:Zirconia ceramics(ZrO2)

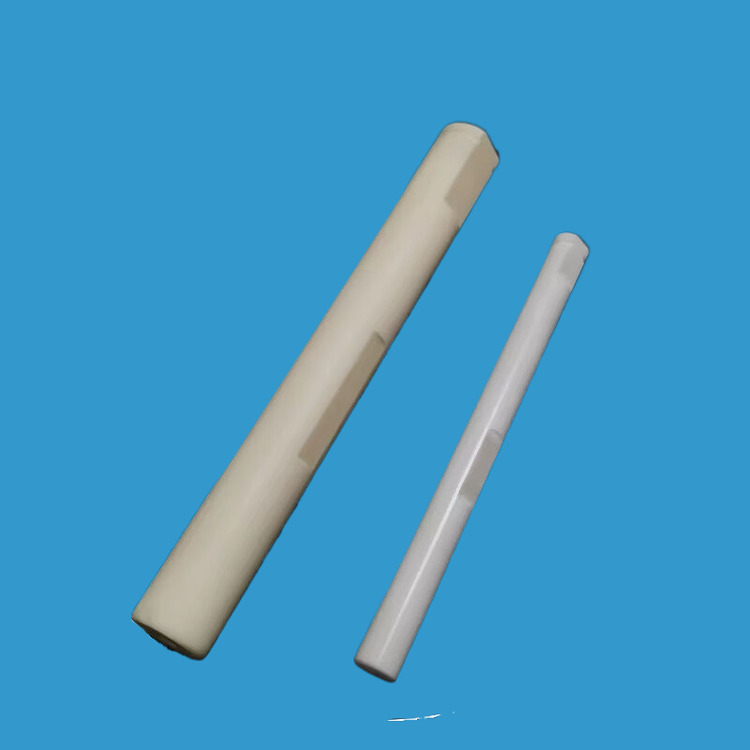

General sizes:Length max up to 350mm

Delivery times:2 -25 days(depends on the quantity)

Density:6.05g/cm3

Hardness (HV):1200MPa

tolerance: 0.001mm... etc

Features:high hardness and corrosion resistance...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

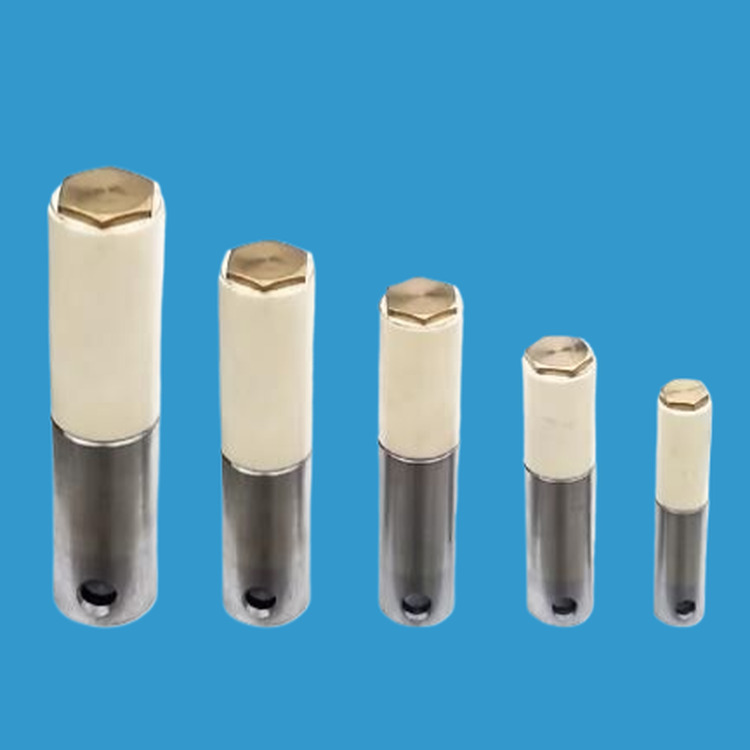

Zirconia ceramic plunger, referred to as zirconia plunger, is a new material with high hardness, high density, wear resistance, corrosion resistance and other excellent properties. It is made of zirconia ceramic, has good chemical stability and thermal stability, in extreme high temperature, high pressure and other harsh environment can also maintain excellent physical and chemical properties.

Zirconia ceramic plungers are mainly used in petroleum, chemical and machinery industries, mechanical plungers are used to replace metal plungers, to solve the problem of poor corrosion resistance and low working temperature resistance of metal plungers leading to short equipment life.

Zirconia ceramic plunger inner cavity surface is a fluid structure, no dead Angle, groove. The surface of the inner cavity and the surface of the plunger are processed to the mirror by advanced high-precision internal and external cylindrical grinding machine. The external surface of the ceramic is polished by vibration, which is convenient for cleaning and disinfection.

Zirconia ceramic plungers have the following main properties

1. High hardness: The hardness of zirconia ceramic material is about 10 times more than that of ordinary metal, enough to resist any form of wear and corrosion.

2. High density: The density of zirconia ceramics is large, and it can effectively resist external forces and friction in use.

3. Wear resistance: Zirconia ceramics have excellent wear resistance to ensure the long-term reliability and safety of the work.

4. Corrosion resistance: Zirconia ceramics have good corrosion resistance to acid, alkali and other chemicals, and can work in a variety of harsh environments.

Zirconia ceramic plunger for application

Zirconia ceramic plungers are widely used in various demanding industrial and scientific research fields. Such as:

1. In the petrochemical industry, zirconia ceramic plungers can be used as sealing elements for corrosive media pipelines.

2. In the nuclear industry, natural gas, aerospace and other high-tech fields, zirconia ceramic plungers are widely used as high temperature and high pressure seals for valves, pipelines and so on.

3. In the field of biomedicine, zirconia ceramic plungers can be used as parts of various instruments for tissue electrodes.

Processing service of zirconia ceramic plunger

Bending, Welding, Cutting, Punching, Decoiling, Moulding, Grinding, Milling, Drilling, CNC, Lapping, Polishing, Glazing, Laser Cutting, Honing

length(mm) | diameter(mm) |

90 | 12 |

82 | 4 |

88 | 7 |

47 | 6 |

49 | 2 |

47 | 8 |

78 | 5 |

76 | 6 |

42 | 3 |

70 | 7 |

74 | 4 |

40 | 11 |

44 | 17 |

113 | 1 |

62 | 5 |

105 | 3 |

100 | 10 |

70 | 10 |

106 | 18 |

57 | 2 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.