Zirconia ceramic bushing High strength high hardness and wear resistance Zro2 bushings

Ceramic materials are available:Zirconia (Zro2)machinable ceramic...etc

General sizes:8 mm,14 mm,22 mm,16 mm,17 mm,24 mm,30 mm,34 mm

Cylindricity: up to 0.004mm

Linear tolerance: up to 0.001mm

Features:wear resistance and friction resistance...

Customized:Can be custom for special sizes and shapes

Delivery times:2 -25 days(depends on the quantity)

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Zirconia ceramic bushing is mainly made of zirconia ceramic, zirconia ceramic bushing is a widely used parts in mechanical equipment, industrial pipes and other fields, mainly play a role in protection and buffering.

Raws of zirconia ceramic bushing

TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)

Specifications of zirconia ceramic bushing

Inside diameter (d) : generally from 4mm to 130mm.

Outer diameter (D) : generally ranging from 6 mm to 150 mm.

Length (L) : Generally from 10 mm to 250 mm.

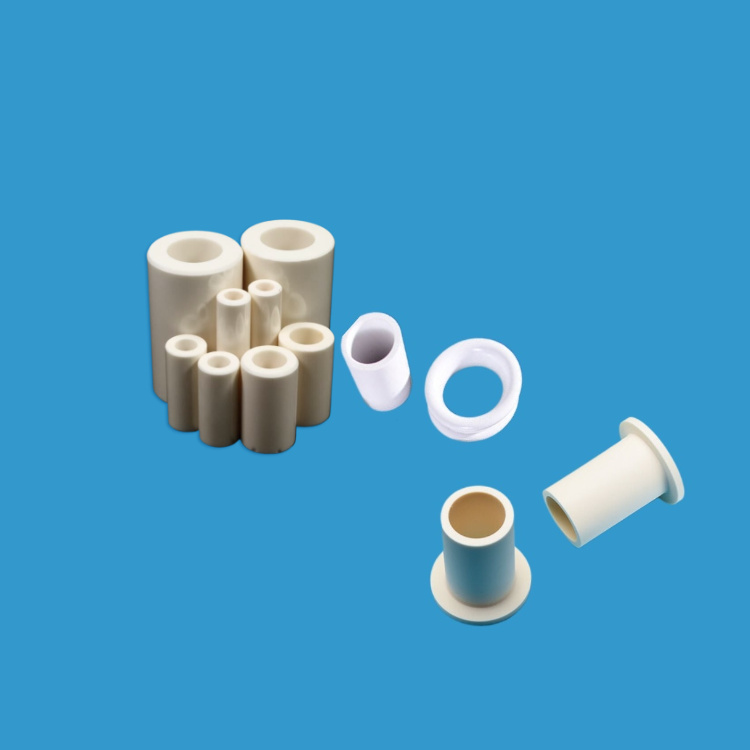

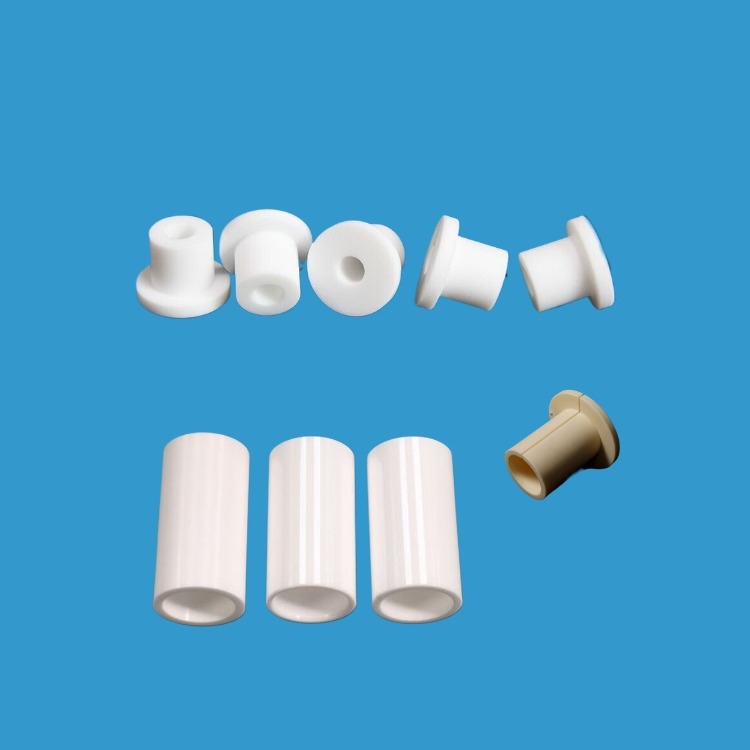

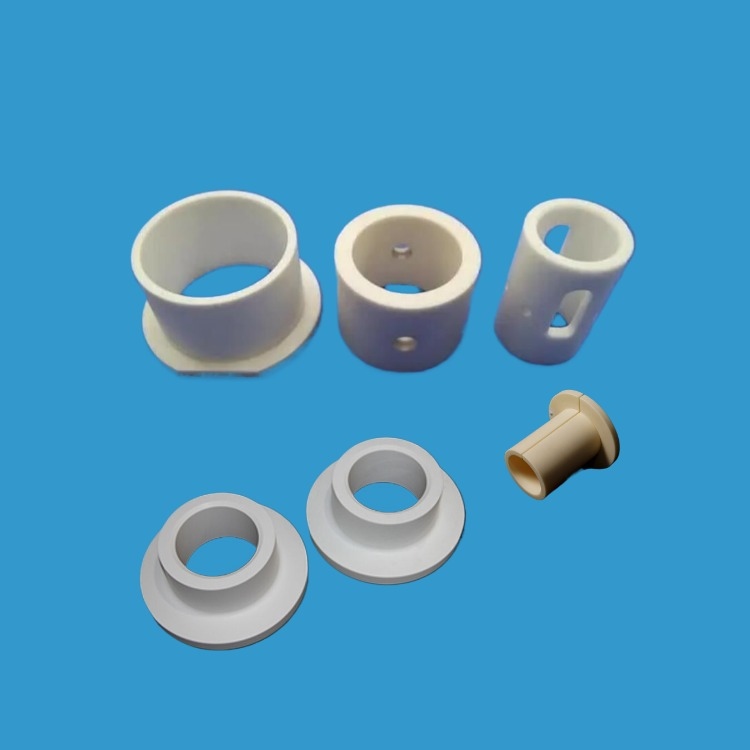

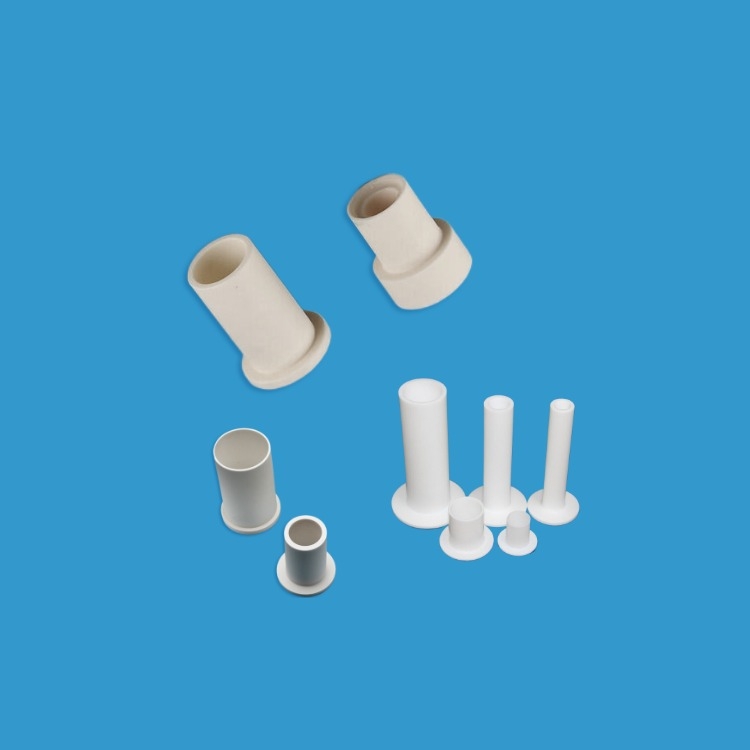

Types of zirconia ceramic bushing

1, straight set zirconia ceramic bushing. Straight sleeve is a kind of light casing, can be used to protect bearings, drive shaft, etc., with good anti-corrosion, anti-wear performance.

2. Special-shaped zirconia ceramic bushing.

3, flange sleeve zirconia ceramic bushing.

4, other types of zirconia ceramic bushing.

The main features of zirconia ceramic bushing

1. High melting point: The melting point of zirconia is very high, reaching more than 2700 degrees Celsius, which makes the zirconia ceramic bushing have good stability in high temperature environment.

2. High hardness: The hardness of zirconia is very high, second only to diamond, so zirconia ceramic bushing has a wide range of applications in the manufacture of wear-resistant parts and tools.

3. Good chemical stability: zirconia is not easy to be oxidized or corroded at high temperatures, so zirconia ceramic bushing is often used in the manufacture of high temperature furnace tubes, thermocouples and other corrosion resistant, high temperature resistant equipment.

4. Excellent electrical insulation performance: zirconia has good electrical insulation performance, zirconia ceramic bushing can be used to manufacture electronic ceramics, capacitors and other electronic components.

The role of zirconia ceramic bushing

1. Protective effect

Zirconia ceramic bushings are protective and can provide an additional layer of protection on the surface of the object to prevent damage such as impact, scratches and wear.

2. Prevent friction

Zirconia ceramic bushings also prevent friction.

zirconia ceramic bushing size charts

| Inside diameter: | Outside diameter: | length: |

| 18mm | 18mm | 24.5mm |

| 20mm | 19mm | 25mm |

22mm | 20mm | 26mm |

| 24mm | 22mm | 28mm |

| 32mm | 25mm | 35mm |

| 35mm | 26mm | 39mm |

| 40mm | 27mm | 40mm |

| 44.933mm | 28mm | 42mm |

| 45mm | 30mm | 45mm |

| 50mm | 32mm | 49mm |

| 74.613mm | 54mm | 240mm |

| 74.93mm | 55mm | 260mm |

| 75mm | 58mm | 280mm |

| 76.2mm | 60mm | 300mm |

| 79.908mm | 70mm | 340mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.