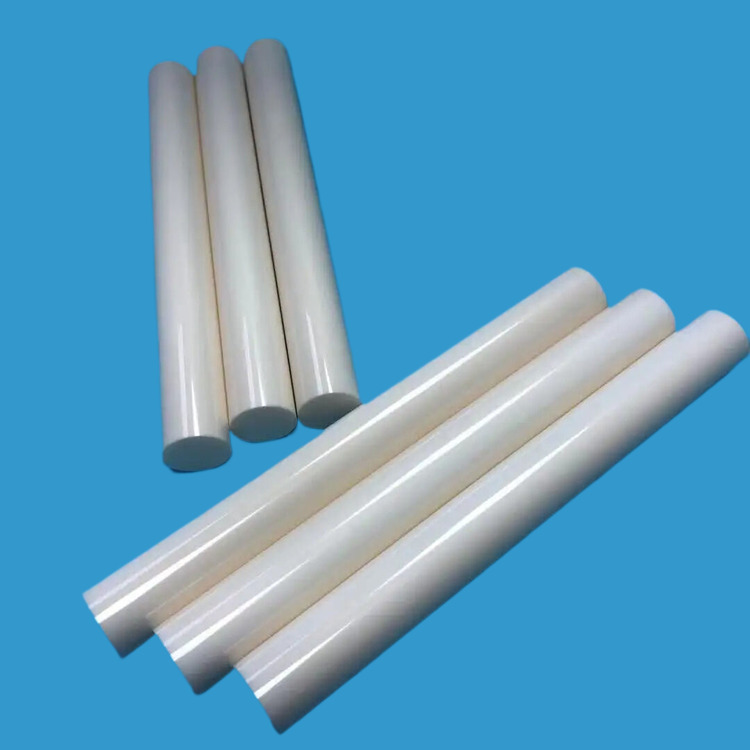

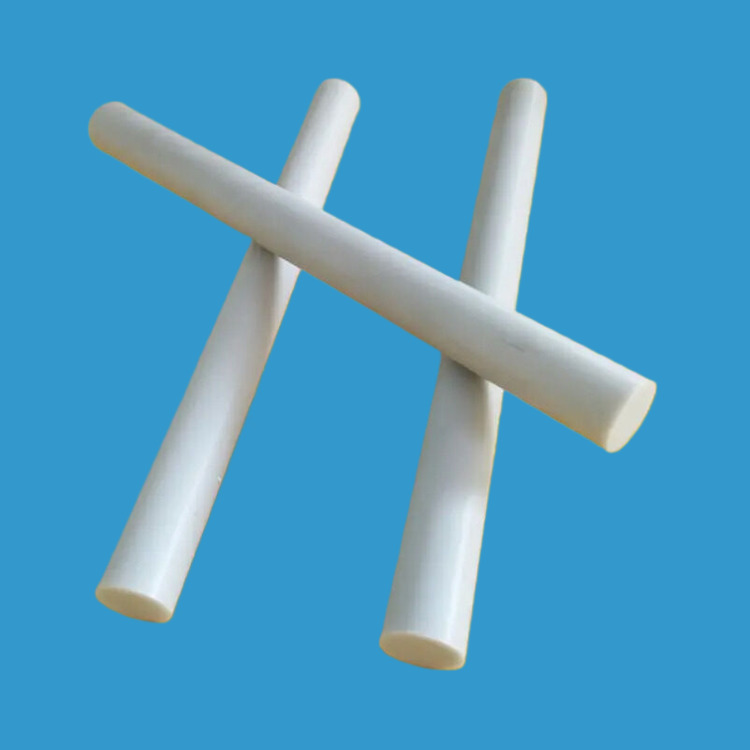

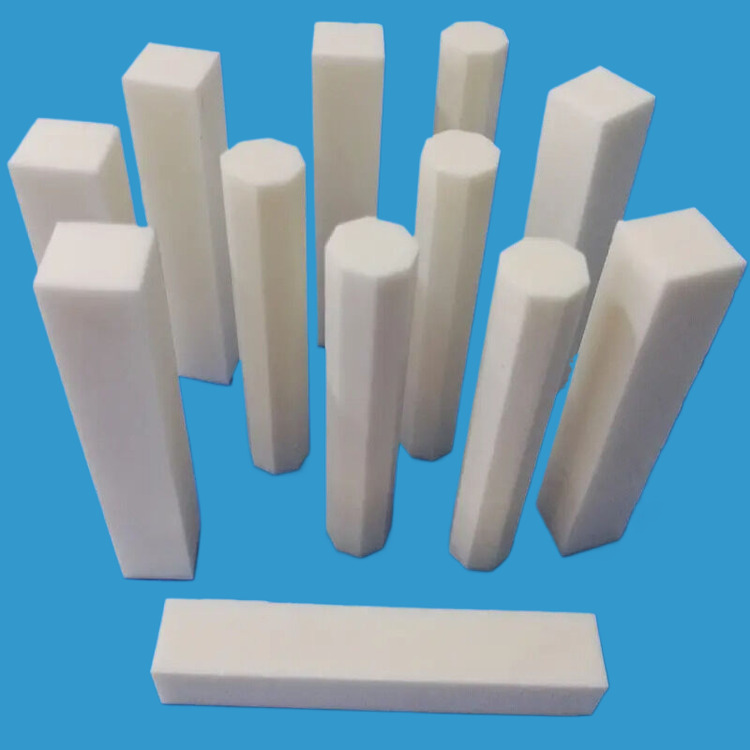

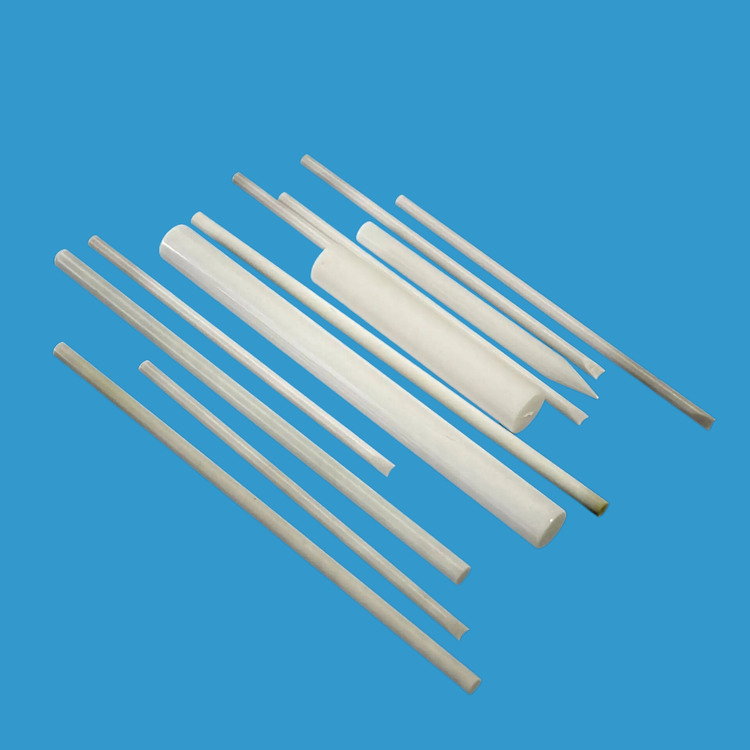

Alumina ceramic insulator rod high mechanical strength good high voltage ceramic rod

Material:alumina al2o3

Purity :95%-99.7%

Wall thinkness:0.25-20mm

Size:Customized

Compressive Strength:850 Mpa

Surface:smooth,verticle,Yellow, White

Shape: Cylinder

Features: high temperature resistance, corrosion resistance, wear resistance, high voltage resistance

Rockwell hardness :≥80 HRA

MOQ:1qtyPayment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Characteristics of alumina ceramic insulation

Alumina ceramic insulator rod is a ceramic material with alumina as the main raw material. Due to its unique physical and chemical properties, alumina ceramic insulation has the following characteristics:

1. Excellent high temperature performance: alumina ceramic insulator rod insulation material can still maintain its insulation performance at high temperature, with good heat resistance and thermal shock resistance.

2. Good high voltage insulation: alumina ceramic insulator rod has excellent insulation performance and can withstand the use of high voltage environment.

3. Good corrosion resistance: alumina ceramic insulator rod has excellent chemical stability, can be used in acid, alkali and other corrosive environment, is not easy to be corroded by chemical substances.

4. High mechanical strength: alumina ceramic insulation material has high mechanical strength and hardness, and is not easy to wear or break.

5. Excellent processing performance: alumina ceramic insulator rod has good processing performance, can be precision machining, welding, assembly and other processes.

Application of alumina ceramic insulation

Alumina ceramic insulator rod are widely used in power, electronics, chemical, machinery manufacturing and other industries.

Alumina ceramic insulator rod has excellent insulation properties , which makes it play an important role in the fields of electronics, machinery and so on. In the electronic field, alumina ceramic rod is commonly used as the base of electronic components, insulator and other components, its excellent insulation performance can effectively protect the working stability of electronic components. In the mechanical field, alumina ceramic rod because of its high hardness and wear resistance, is often used in the manufacture of bearing, tiles and other friction and wear parts, can extend the service life of mechanical equipment. In addition, alumina ceramic rod also has the characteristics of high temperature resistance, corrosion resistance, can be used in a variety of harsh working environments, such as the aerospace field in the high temperature environment of the aircraft engine components

Material:alumina al2o3

Purity :95%-99.7%

Type:Insulating Ceramics, Insulating Ceramics, Electrothermal Ceramics

Wall thinkness:0.25-20mm

Size:Customized

Density:3.26 G/cm3

Compressive Strength:850 Mpa

Surface:smooth,verticle,Yellow, White

Shape: Cylinder

Bending strength :≥290MPa

Features: high temperature resistance, corrosion resistance, wear resistance, high voltage resistance

Scope of application: Used in electronics, machinery, chemical industry, metallurgy, textile, electric power, etc

Rockwell hardness :≥80 HRA

Type: Ceramic rod

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.