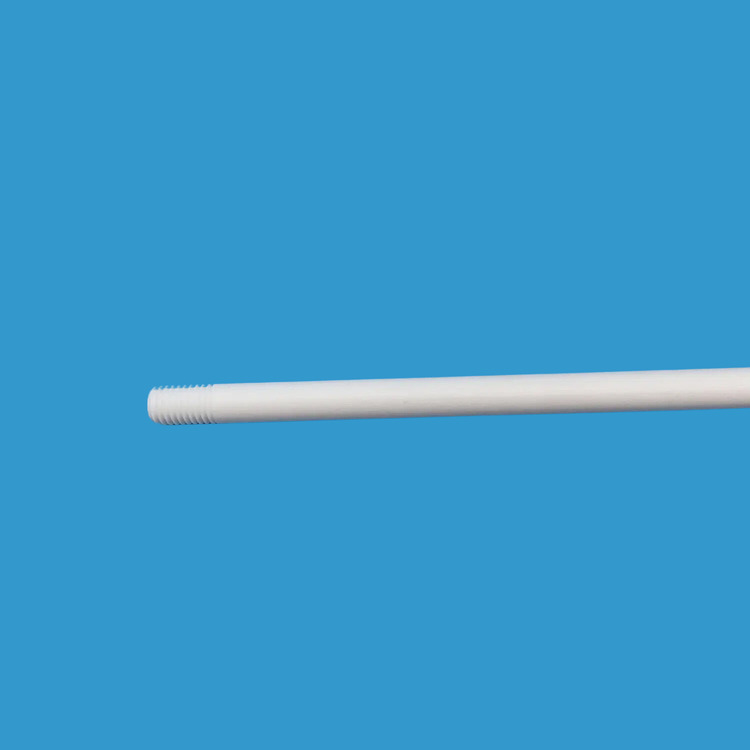

Alumina ceramic rod high purity 95 to 99% al2o3 alumina ceramic solid rod

Sizes:Mini-OD: 0.02mm;Max-length: 500mm

Tolerance :±0.01

Glaze: Yes

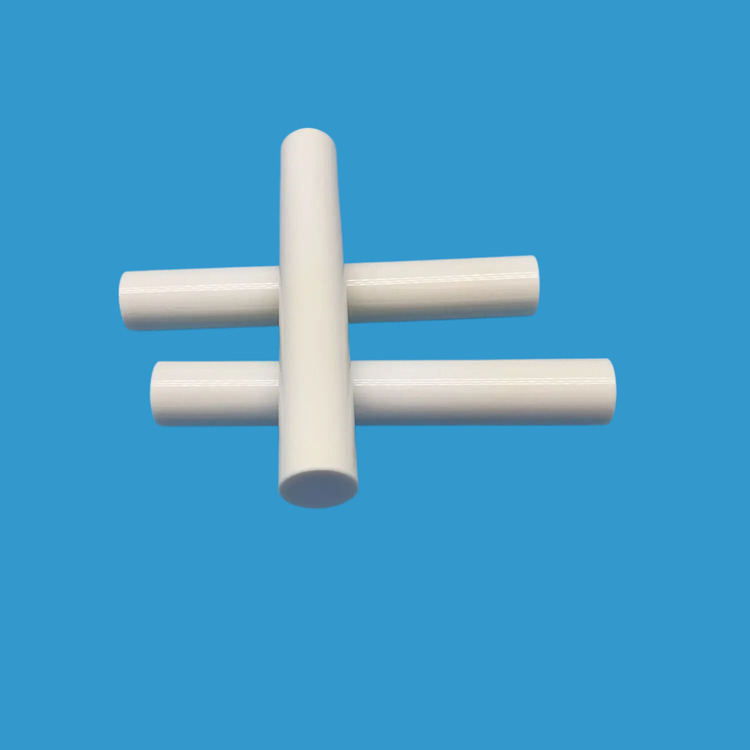

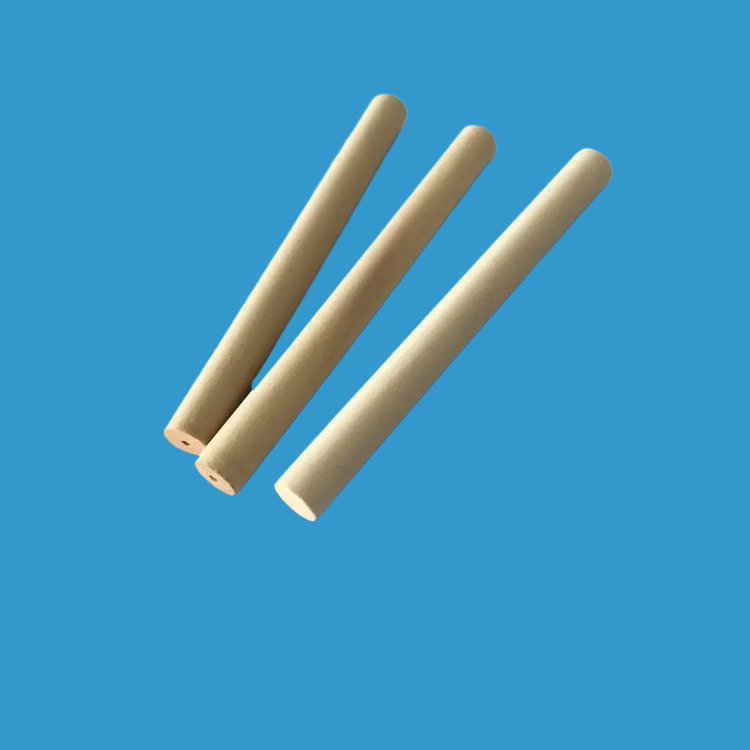

Color: White, beige or other colors are acceptable

Processing customization: Yes

Material: Alumina AL2O3

Function: high temperature resistance insulation wear resistance oxidation resistance chemical resistance

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

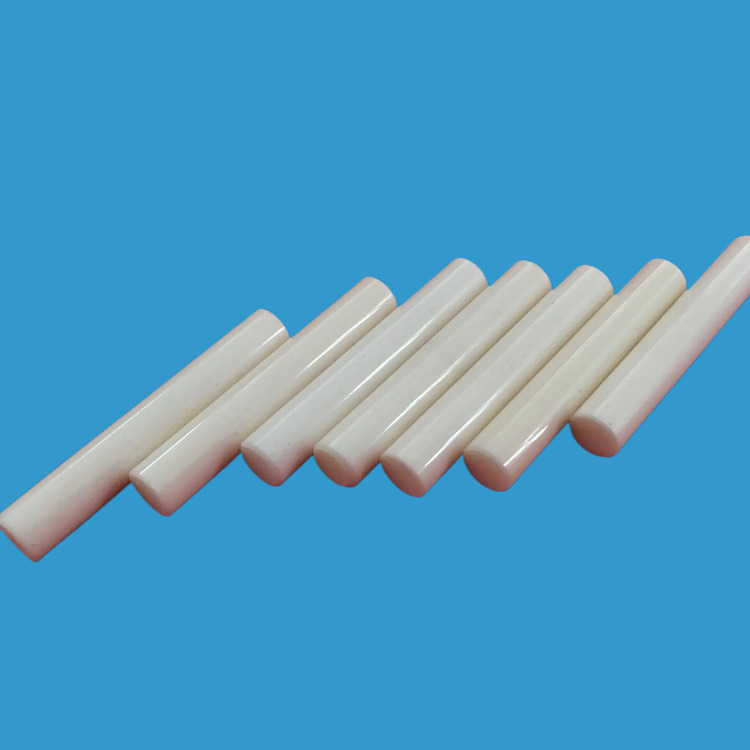

The high temperature resistance of alumina ceramic rod can reach more than 1700 degrees, with good conductivity, mechanical strength and high temperature resistance, the density of alumina ceramic rod is relatively low and convenient for transportation, but the toughness of alumina ceramic rod is not good, easy to break and break; Alumina ceramic rod is widely used, has been soaked in electronic appliances, mechanical parts and other fields!

Alumina ceramic rod has high temperature resistance, wear resistance, high mechanical strength, excellent insulation performance, high precision, straightness and surface finish, and is generally used as a plunger in medical diagnostic equipment, precision instruments, fine chemicals, precision casting and other fields.

The alumina ceramic rod has the characteristics of insulation, abrasion resistance, high temperature resistance, high pressure resistance, chemical corrosion resistance, oxidation resistance, non-magnetic, non-static electricity and good self-lubrication performance. Widely used in computer, communication, power supply, frequency converter, instrumentation, industrial equipment, electrical appliances, motors and other fields.

Alumina ceramic solid rod:

1, alumina ceramic rod has a strong weather resistance, high temperature resistance ceramic rod using zirconia ceramic or alumina as production

2, has strong stability, ceramic rod ceramic shaft is easy to maintain, there is no need to add any anti-corrosion paint or protective layer on the surface

3, high wear resistance, ceramic rod using high-precision raw materials, in the process of high temperature firing to enhance the mechanical strength and hardness of ceramics, so the ceramic rod has impact resistance, long-term use of shape will not appear damage.

The sintered alumina ceramic rod needs to be finished to meet the requirements of dimensional accuracy and performance. The finishing process mainly includes grinding, polishing, cutting and so on. Grinding and polishing can improve the surface finish and dimensional accuracy of ceramic rod. Cutting is used to cut the ceramic rod to the desired length.

Packing: carton, wooden case or as required

Product name: Isostatic press forming 1700℃ high temperature sintered alumina ceramic rod

Forming process "isostatic press forming"

Firing temperature :1700℃

Finishing: external grinding

Tolerance :±0.01

Glaze: Yes

Color: White, beige or other colors are acceptable

Processing customization: Yes

Material: Alumina AL2O3

Function: high temperature resistance insulation wear resistance oxidation resistance chemical resistance

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.