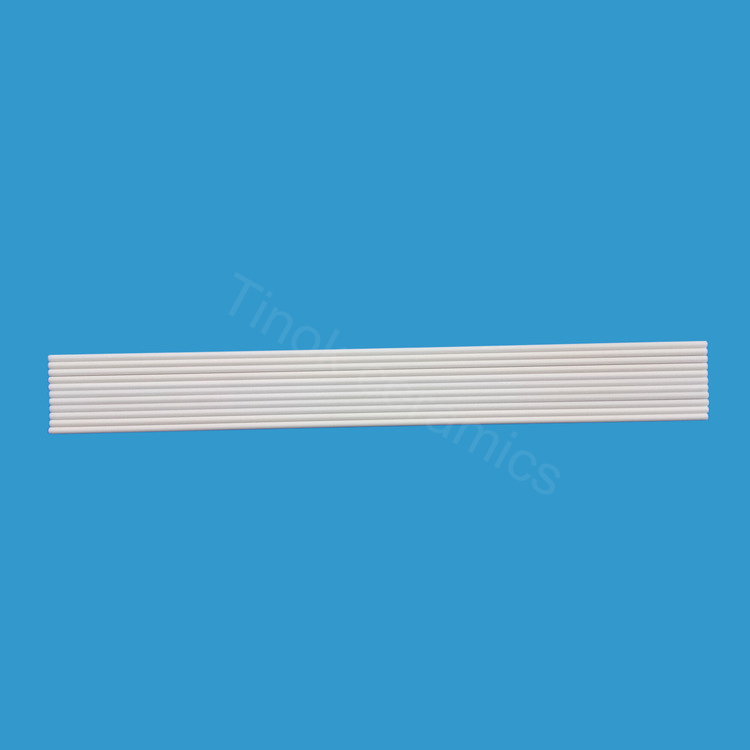

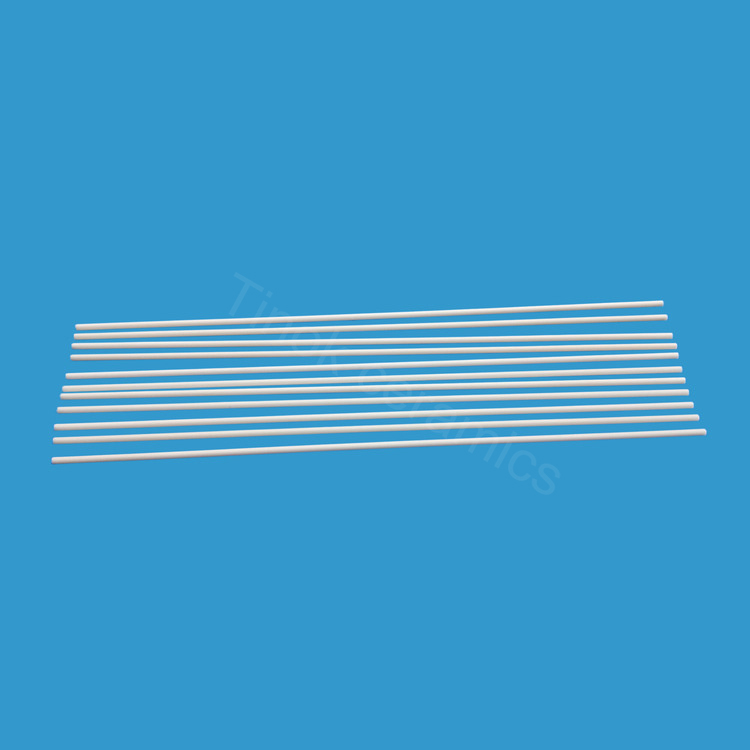

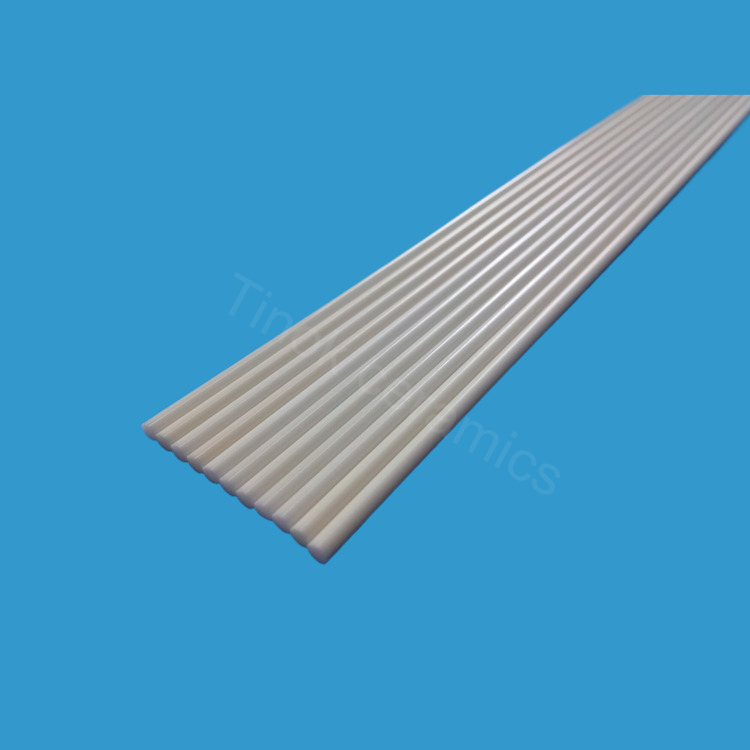

high temperature heat resistance ceramic rods and bars

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Mini-OD: 0.02mm;Max-length: 500mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

What is the maximum temperature for ceramic rods?

Ordinary alumina or zirconia ceramics can withstand high temperatures above 1000 ° C when heated, while the peak temperature of advanced ceramics such as silicon carbide ceramics and silicon nitride ceramics can reach more than 1500 ° C. According to the material classification of ceramics, their ability to withstand high temperatures is different.

In the high temperature state, the rod can still maintain good physical properties, do not melt, maintain wear resistance, strength, insulation and so on.

Whether it is in the use of high-strength environment resulting in high temperature of the rod or in the case of high voltage resulting in heat, the high temperature resistance of the rod is still better than most metals.

The high temperature resistance of industrial ceramics is stronger, and some types of industrial ceramics can withstand high temperatures of about 2600 degrees.

For example, the melting point of alumina ceramics is 2050℃, and the boiling point is as high as 3000℃. This ceramic is favored in industrial applications for its excellent heat resistance.

Density:3.70,3.80, 3.90, 3.92 (g / cm3 )

Compressive Strength @ 25 C:2229Mpa/ 2091Mpa/ 2512Mpa/ 2350Mpa

Tensile Strength @ 25 C:200Mpa/200Mpa/248Mpa / 252Mpa

Flexural Strength @ 25 C:331Mpa /276Mpa /324Mpa /320Mpa

Elastic Modulus @ 25 C:290GPa /331GPa /366GPa /380GPa

Maximum Working Temp:1650℃/1700℃

Thermal Conductivity @ 25 C:20.8 ,28.1, 30.7 ,31.6 (W / m-Deg K)

Usage:Industrial Ceramic

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.