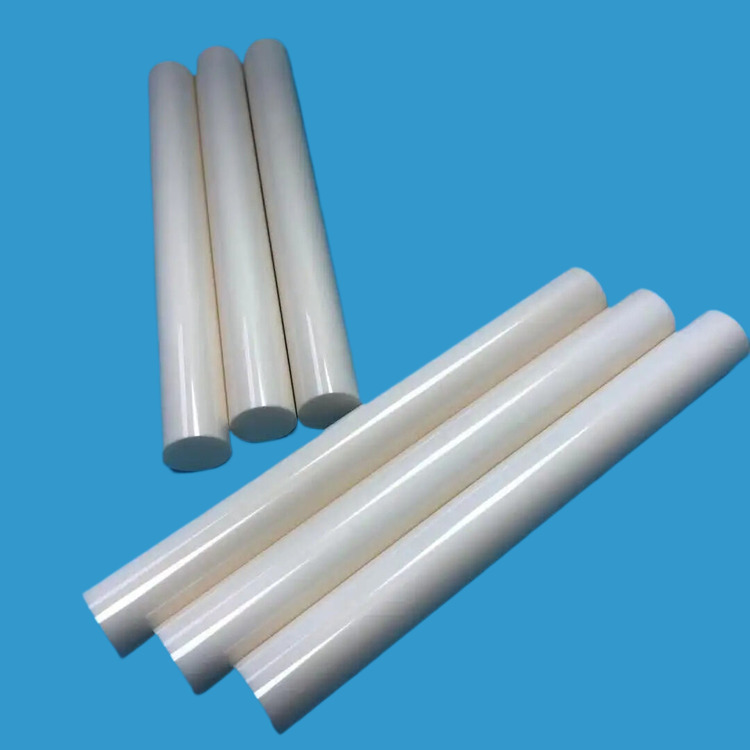

Machinable ceramic rod alumina zirconia ceramic rod

Tolerance:±0.01 mm or custom

Processing Service:Punching,Grinding,moulding

Application:Industrial Ceramic/Machinery/Refractory/Accessory

Pack:Carton or wooden case with pallets inside

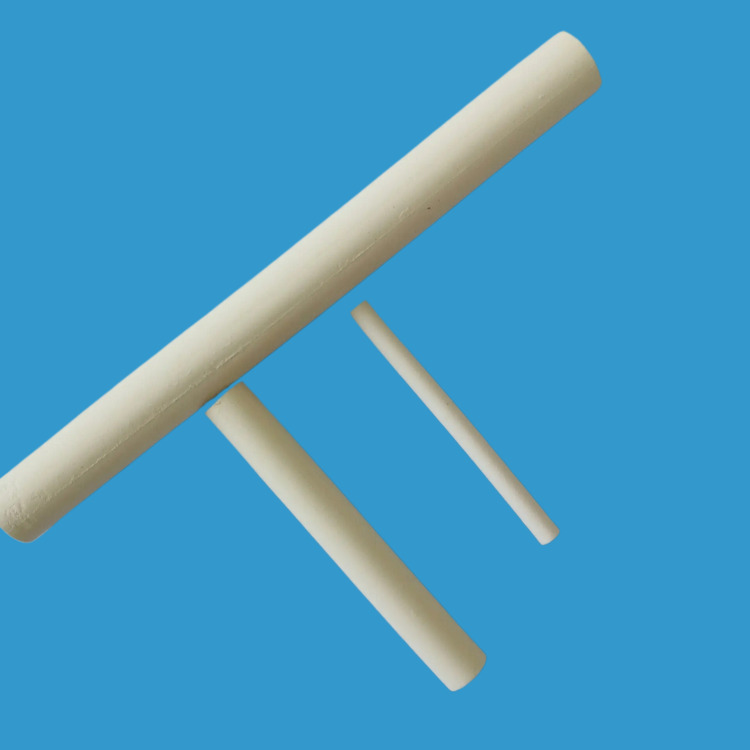

Color:Light Yellow/White

Shape:Custom-shaped

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

machinable ceramic rod can generally be secondary processing, such as processing into tubes, gaskets, rings and so on.

machinable ceramic rod generally uses zirconia ceramics or alumina ceramics as raw materials for turning, milling, planing, grinding, drilling, cutting, tapping and other processing to achieve high accuracy; Dimensional accuracy: up to 0.001; Finish: Up to mirror!

A machinable ceramic rod polished

After the machinable ceramic rod is sintered out, the surface is very rough, and it needs to be polished by centerless grinding and grinding equipment. Our polished ceramic rod can achieve the effect of atomizing mirror!

Machinable ceramic rod chamfer

machinable ceramic rod chamfer is 45 degrees, 60 degrees, 90 degrees, we have a ready-made grinding wheel, ceramic bar can pour different angles;

Machinable ceramic rod grooves

Ceramic rods can be slotted on one side or two sides! Slot can be opened according to different customer requirements;

Ceramic rods punched

Machinable ceramic rod straightness machining

The straightness of the Machinable ceramic rod is related to the length of the ceramic rod, the longer the easier to bend, generally 100mm long ceramic rod we can control the straightness of 0.1mm,300mm long straightness of 0.3mm;

Machinable ceramic rod cylindrical machining

The outer circle of the ceramic rod generally needs to be cylindrical grinding, and the roundness of the ceramic rod can reach 0.002mm

Material:ALUMINA

Tolerance:±0.01 mm or custom

Processing Service:Punching,Grinding,moulding

Application:Industrial Ceramic/Machinery/Refractory/Accessory

Pack:Carton or wooden case with pallets inside

Color:Light Yellow/White

Shape:Custom-shaped

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.