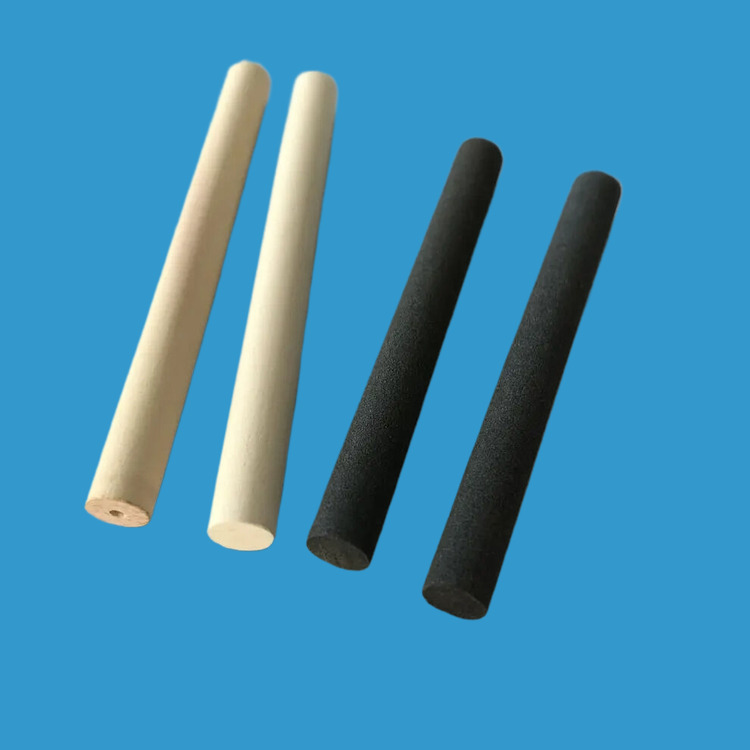

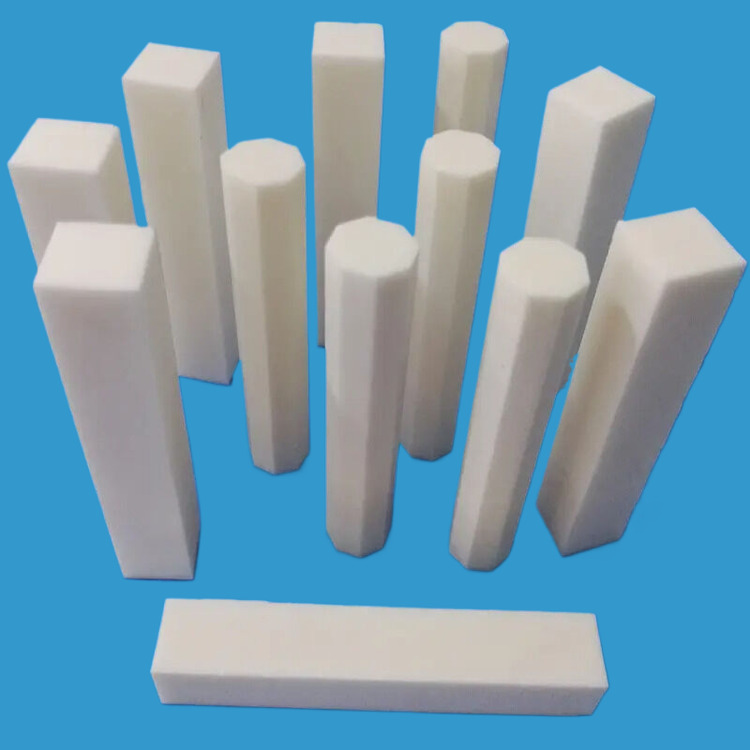

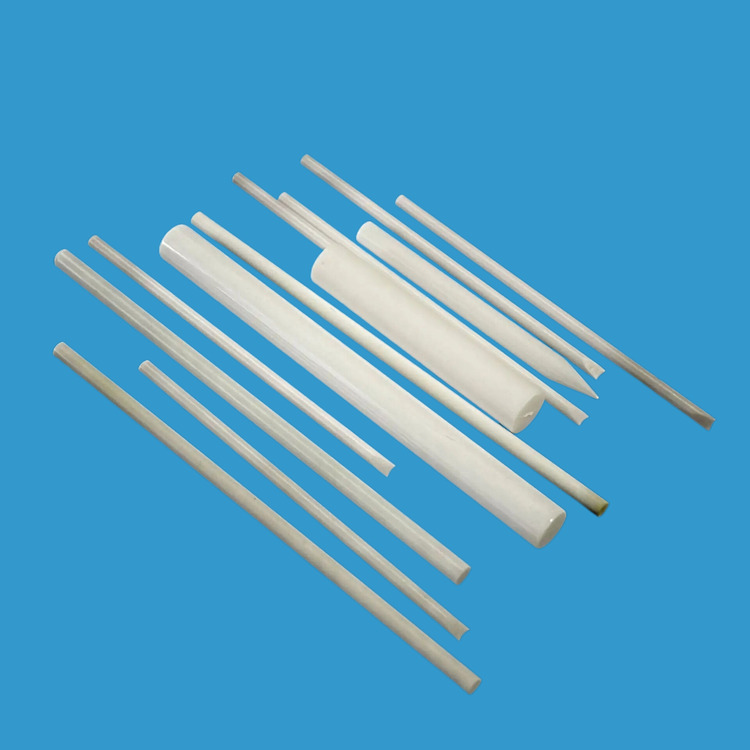

Wear resistance ceramic rod hardness and fracture toughness al2o3 alumina zro2 zirconia ceramic rod

The smallest diameter of the ceramic rod is 0.2mm, the largest is 150mm, the length can reach 480mm, and the tolerance can be customized according to the requirements.

Materials:al2o3 alumina OR zro2 zirconia ceramic

MOQ:1qtyPayment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

The hardness and fracture toughness of ceramic materials are the key factors affecting the wear rate, and the wear rate of ceramic materials with high hardness and fracture toughness is lower. In view of the goal of improving the hardness and fracture toughness of ceramic materials, compared with ordinary metals or plastics, wear-resistant ceramic rod have the following advantages: high hardness, high strength, good wear resistance, more than 100 times more than manganese steel, high temperature resistance, acid and alkali corrosion resistance, light weight, only half of steel, can greatly reduce the load of equipment.

Application fields of wear resistance ceramic rod

Ultrafine grinding equipment, fine chemicals, electronic paste, semiconductors, new energy, medical devices, precision casting, structural ceramics, refractory materials, electronic communications, petrochemical, aerospace, mechanical manufacturing, optical fiber connectors, battery materials and other high-precision fields.

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.