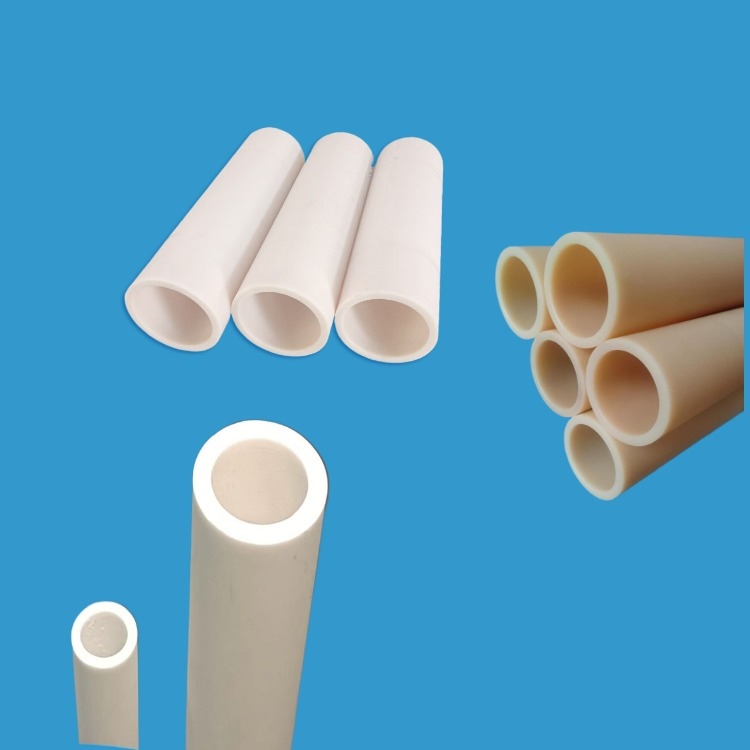

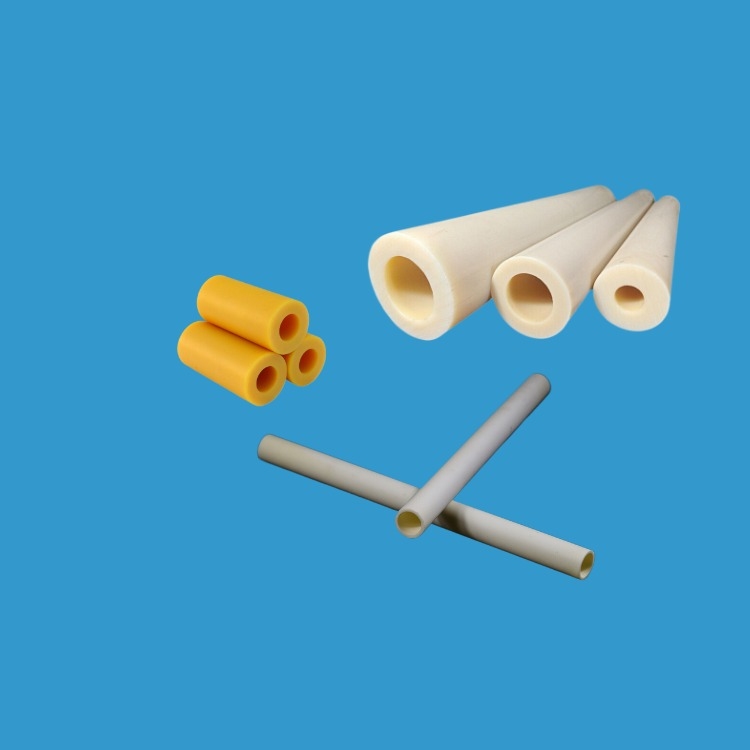

Ceramic protecting tubes high temperature resistant thermal protection alumina ceramic tubes

Ceramic materials are available:Alumina (Al2O3) 95% to 99.99% ...etc

General sizes:Diameter (520mm) Wall thickness (110mm) Length (500mm)

Temperature range: 0-1800℃

Application: vacuum furnace, industrial furnace, electromechanical equipment

Features:Can withstand 1800℃ high temperature, high insulation

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic protective tubes are widely used in situations where components such as heaters or thermocouples need to be isolated from high-temperature melt or corrosive gases or dust.

Alumina ceramic protection tube features:

High strength, corrosion resistance;

Good thermal conductivity;

In high temperature aluminum melt, it has a good non-sticking effect.

Long service life; The service life of pure silicon nitride material can be as long as several years;

Material: AL2O3

Temperature range: 0-1800℃

Application: vacuum furnace, industrial furnace, electromechanical equipment,electronic appliances, mechanical seals, insulation, etc

Why do thermocouples need ceramic tubes

Thermocouples are exposed to extremely harsh environments, sometimes to extremely hot fires, and sometimes to mechanical shock, moisture erosion, and other problems. In order to enhance the protection performance and prolong the service life of the thermocouple, ceramic tubes are usually used to protect the thermocouple.

Ceramic tube has high strength, high heat resistance, high corrosion resistance, high insulation and other outstanding properties, can protect the thermocouple from fire, mechanical impact, moisture and corrosion in harsh environments, reduce the failure rate of the thermocouple, so as to ensure the stability and accuracy of the measurement results.

In addition, the ceramic tube material itself has the characteristics of oxidation resistance, stability, high mechanical strength, can withstand high temperature, acid, humidity and other environments, maintain long-term stability, extend the service life of the thermocouple, and reduce maintenance costs.

Thermal protection ceramic tubes sizes charts

OD(mm) | ID(mm) | Length(mm) |

50 | 48 | 379 |

62 | 60 | 36 |

3 | 1 | 379 |

35 | 33 | 292 |

41 | 39 | 598 |

69 | 67 | 525 |

5 | 3 | 196 |

69 | 67 | 427 |

44 | 42 | 360 |

16 | 14 | 495 |

23 | 21 | 317 |

8 | 6 | 534 |

50 | 48 | 502 |

5 | 3 | 409 |

54 | 52 | 481 |

70 | 68 | 151 |

31 | 29 | 74 |

63 | 61 | 594 |

35 | 33 | 191 |

49 | 47 | 467 |

52 | 50 | 539 |

11 | 9 | 244 |

11 | 9 | 24 |

36 | 34 | 360 |

17 | 15 | 68 |

12 | 10 | 506 |

64 | 62 | 298 |

34 | 32 | 195 |

63 | 61 | 468 |

11 | 9 | 341 |

66 | 64 | 20 |

39 | 37 | 346 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.