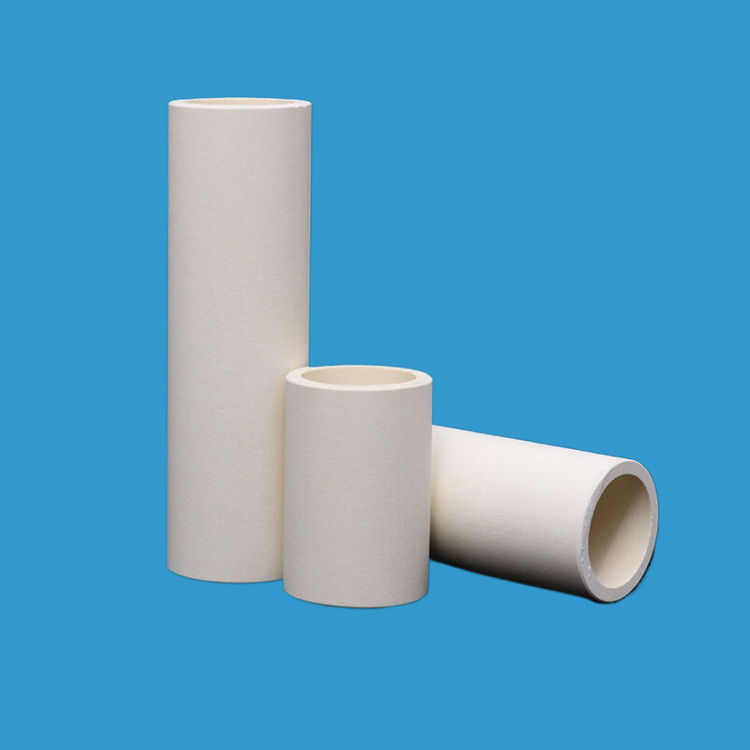

Alumina ceramic tubes high purity 95 97 98 99 al2o3 aluminum oxide ceramic tube

Name: Alumina ceramic tube

Content: 95%99% alumina

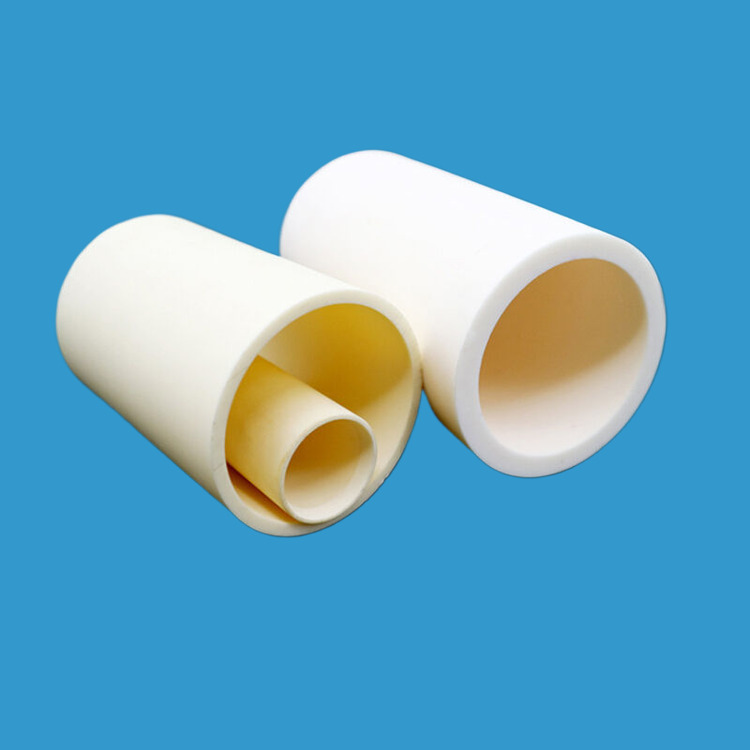

Color: White or ivory

Working temperature: 1300℃

Features: Excellent electrical insulation, good thermal conductivity, high hardness, good wear resistance

Uses: High voltage transmission, electric power

Finishing: can be machined inside and outside round grinding

Tolerance :±0.01

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Alumina ceramic tube is formed by isostatic pressing process, regular size, complete specifications, with high purity, good compactness, good wear resistance, corrosion resistance, high temperature resistance, low wear, not polluted by abrasive and so on.

Name: Alumina ceramic tube

Content: 95%99% alumina

Color: White or ivory

Working temperature: 1300℃

Features: Excellent electrical insulation, good thermal conductivity, high hardness, good wear resistance

Uses: High voltage transmission, electric power

Finishing: can be machined inside and outside round grinding

Tolerance :±0.01

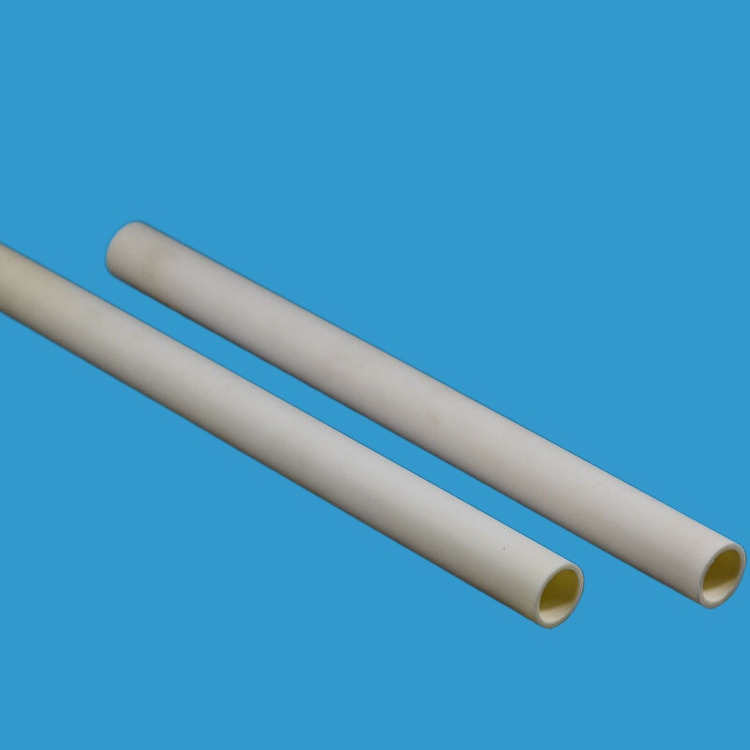

The length used in industry is generally 1.2m long, and the test is generally 0.5m. The diameter is used in industry, from 10mm to 41mm. Generally use 10mm or 25mm diameter

Alumina ceramic tube is an important industrial ceramic material, which has a wide range of applications in industry.

The following are its main uses and functions:

1. Corrosion resistance and high temperature resistance: alumina ceramic tubes have very high corrosion resistance and high temperature resistance, which makes it often used in the petroleum and chemical industry as corrosion and high temperature resistant pipes, valves, pumps and other various equipment parts. For example, in cracking furnaces operating at high temperatures, alumina ceramic tubes can be used as furnace body and insulation wall materials, effectively extending equipment life and improving production efficiency.

2. Applications in the electronic and electrical industry: Alumina ceramic tubes are also widely used in the electronic and electrical industry, such as high-voltage capacitors, IGBT modules, power electronics, highly ionized vacuum systems, semiconductor manufacturing equipment and other fields. Because of its excellent insulation, high frequency voltage resistance and heat resistance, it is widely used in the manufacture of a variety of high temperature, corrosion and pressure resistant electronic devices.

3. Industrial ovens and machines: alumina ceramic tubes have good electrical insulation, high chemical resistance and low thermal expansion, so these ceramic tubes are also widely used in industrial ovens and machines.

4. Semiconductor manufacturing: High purity alumina materials are ideal for manufacturing alumina components for CVD, ion implantation, lithography and semiconductor manufacturing.

5. Traditional industry: In traditional industry, alumina ceramics are the ideal choice for products such as spray tubes, gas nozzles and insulators. Because of its ability to retain hardness at high temperatures, it is also used as a material for industrial furnaces and as a protector for high-temperature thermocouples.

6. Heating industry: In industrial applications requiring high temperature resistance, the excellent durability of alumina ceramic tubes makes them the ideal material for the heating industry. Heaters made with it are safer than electric heaters because they reach a preset temperature and maintain it.

The advantages of high purity alumina ceramic tubes are mainly reflected in the following aspects. First of all, it has excellent high temperature resistance. High purity alumina ceramic tube can maintain stable physical and chemical properties in high temperature environment, and will not break due to thermal expansion. Secondly, it has a low thermal conductivity, which can effectively isolate heat transfer and protect the safety of surrounding equipment and personnel. In addition, the high-purity alumina ceramic tube also has excellent corrosion resistance and can be used stably in corrosive media such as acid and alkali for a long time.

Material | Alumina Machinable Ceramics |

Length | 10mm - 200mm |

OD | 0.3mm - 30mm |

Torlerance | +/- 0.001mm |

Surface Roughness | Ra 0.05 |

Shipping | Air Express (DHL/UPS/TNT/ FedEx) |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.