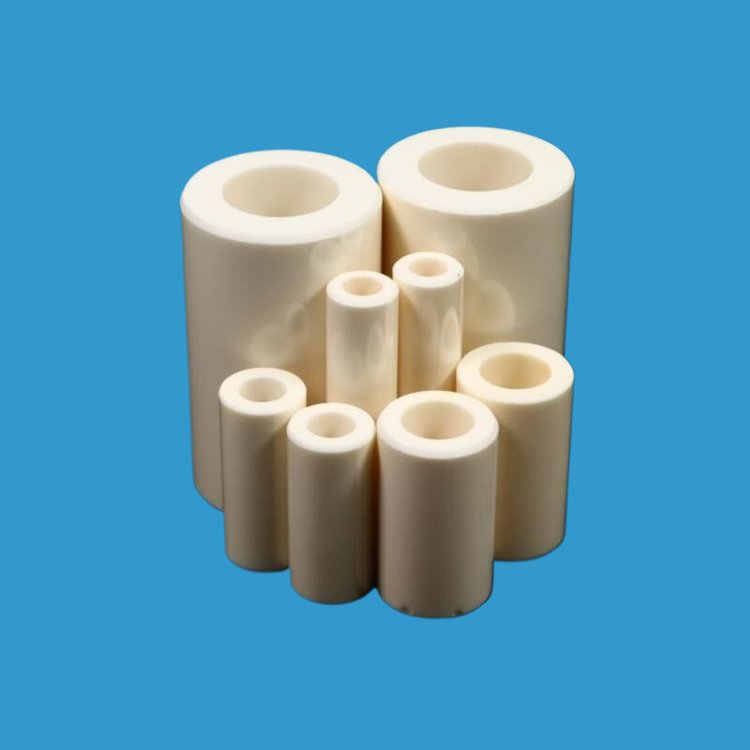

Ceramic lined tube wear and corrosion resistant al2o3 alumina tube high hardness zirconia tube

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

Alumina Ceramic: 96%, 99%, 99.5% Al2O3

Working temperature: 1300℃

Features: Excellent electrical insulation, good thermal conductivity, high hardness, good wear resistance

Uses: High voltage transmission, electric power

Finishing: can be machined inside and outside round grinding

Tolerance :±0.01

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic lined tube play a wear-resistant, corrosion-resistant role

Ceramic linings are usually made of high-performance ceramic materials such as alumina ceramics and silicon nitride ceramics, which have extremely high hardness and wear resistance and can effectively resist wear and erosion in the medium.

Ceramic lined pipe has semicircular ceramic lined pipe, flange ceramic lined pipe, ceramic lined elbow and ceramic lined composite pipe, because of its unique physical and chemical properties, is widely used in various industrial fields. These pipeline lining materials are usually made of alumina ceramics, silicon carbide ceramics, boron carbide ceramics, etc. has strong chemical stability and mechanical properties, can effectively resist the corrosion of various corrosive media, to ensure the long-term stable operation of the pipeline. In addition, ceramic lined pipe also has the characteristics of good wear resistance, low running resistance, corrosion resistance, wear resistance, high temperature, high pressure and so on, makes it an ideal choice for conveying corrosive media and abrasive granular materials.

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

Alumina Ceramic: 96%, 99%, 99.5% Al2O3

Working temperature: 1300℃

Features: Excellent electrical insulation, good thermal conductivity, high hardness, good wear resistance

Uses: High voltage transmission, electric power

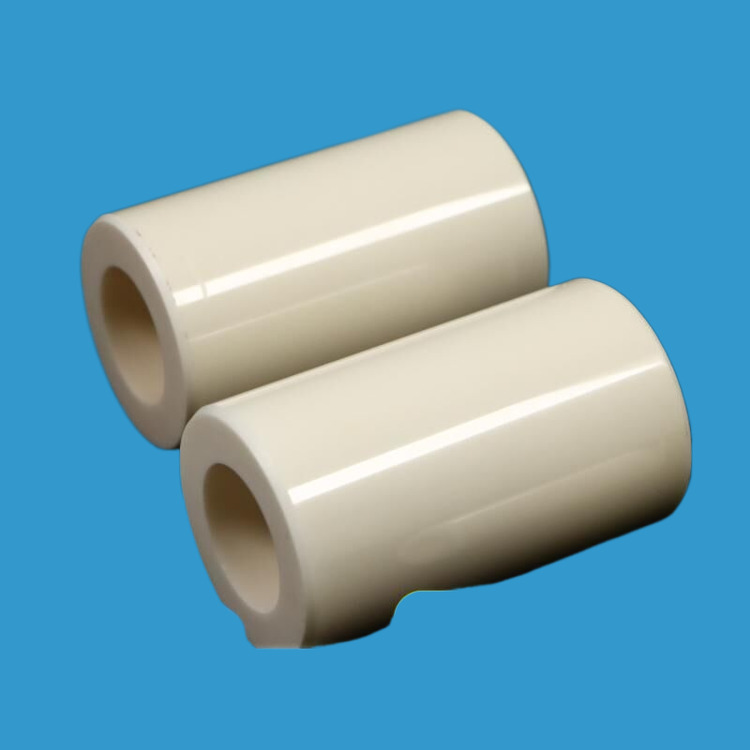

Finishing: can be machined inside and outside round grinding

Tolerance :±0.01

Dimension

The length used in industry is generally 1.2m long, and the test is generally 0.5m. The diameter is used in industry, from 10mm to 41mm. Generally use 10mm or 25mm diameter

Process

Accuracy 0.01-- 0.1mm; Surface machining: accuracy 0.002mm; Cylindrical processing: accuracy 0.002mm; Inner circle processing: accuracy 0.005mm; Polishing: Accuracy 0.005mm.

peculiarity

1. Strong wear resistance: ceramic lined wear-resistant pipes are lined with high-performance ceramic materials, which have strong wear resistance, can effectively resist wear and erosion in the medium, and extend the service life of the pipeline.

2. Excellent corrosion resistance: ceramic materials have excellent corrosion resistance, which can resist the erosion of various acids, alkalis, salts and other chemicals, and the stable operation of well-known pipelines in harsh environments.

3. Good high temperature performance: ceramic lined wear-resistant pipe can maintain stable performance in high temperature environment, will not be deformed or damaged because of high temperature, suitable for a variety of high temperature conveying occasions.

4. Low maintenance cost: Because the ceramic lined wear-resistant pipe has a long service life and a low wear rate, the replacement frequency and maintenance cost of the pipe can be reduced, saving costs for enterprises.

Use

Alumina ceramic tubes are widely used for fluid transportation and protection in harsh environments such as high temperature, high pressure and corrosion. Its main application areas include:

1. Power: alumina ceramic tubes are used for insulation protection and conductor support of power equipment.

2. Chemical industry: alumina ceramic tubes are used in reaction vessels, storage tanks, pipelines and other aspects of chemical equipment.

3. Metallurgy: alumina ceramic tubes are used in high-temperature furnaces, electric furnaces, converter and other aspects of the metallurgical industry.

4. Petroleum: alumina ceramic tubes are used in oil mining, storage and transportation, refining and other aspects.

5. Medical treatment: alumina ceramic tube is used for adsorption, filtration, separation and other aspects of medical equipment.

| Length Range | Length Range | Outside Diameter | Outside Diameter | Inside Diameter | Inside Diameter |

| 4.000-6.875 in | 102-174 mm | 0.031 in | 0.79 mm | 0.005 in | 0.13 mm |

| 4.000-6.875 in | 102-174 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.156 in | 3.96 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 6.876-12.875 in | 175-327 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.047 in | 1.19 mm |

| 4.000-6.875 in | 102-174 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 12.876-18.875in | 328-479 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.000-6.875 in | 102-174 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.