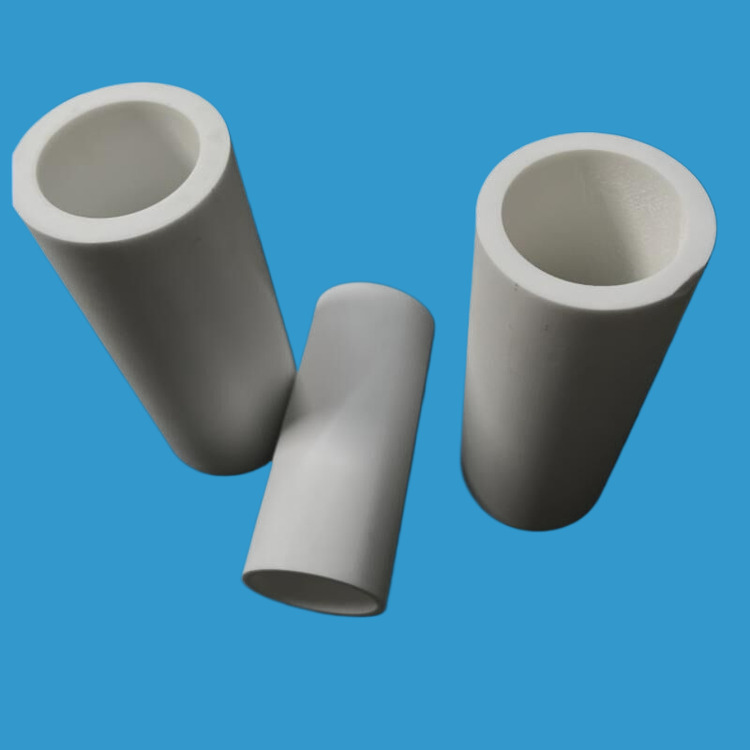

Custom ceramic tube customized high purity alumina tube High hardness zirconia tube

Processing customization: Yes

Specification size: Various specifications size mm

Material Service:

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

Alumina Ceramic: 96%, 99%, 99.5% Al2O3

Silicon Nitride: Si3N4, RBSN, SRBSN, GPSN

Machinable Ceramic: Macor Ceramic

Machining Service:

Laser Cutting

CNC Machining

Cernerless Grinding and Inside Hole Honing

Surface Grinding and Polishing

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Custom ceramic tube is a kind of tube material with wide application fields and excellent properties. It is mainly used in machinery, electronics, metallurgy and other industries, with high temperature resistance, corrosion resistance, wear resistance and good chemical stability. It can be sealed with molybdenum, niobium, tantalum and other metals, and some are used as electric vacuum devices.

Precision ceramic materials have different processing methods according to different performance requirements. At present, the main processing methods include mechanical processing, electrical processing, ultrasonic processing, laser processing and composite processing. The following is a brief introduction to the machining methods of precision ceramics.

Ceramic material machining mainly includes turning processing, grinding processing, drilling processing, grinding and polishing.

Custom ceramic tube order process including customer requirements analysis, design of , mold production, raw material preparation, molding and shaping, sintering, , , stripping surface treatment, quality inspection , packaging and shipment.

Processing Services:

Plane processing, plane dimensions; Accuracy: 0.01mm; Shape accuracy: 0.01mm; Roughness: Ra0.1 ~ 1.6mm;

Cylindrical machining; Outer dimension: 0.01mm; Shape accuracy: 0.01mm; Roughness: Ra0.1 ~ 1.6mm;

Custom ceramic tube polishing

The workpiece is weak cutting, polishing can not improve the dimensional accuracy, shape accuracy and position accuracy, but reduce the surface roughness of the workpiece, improve the brightness of the precision machining. Roughness: Ra0.1

Finishing and post-treatment

Finishing is a crucial step in the production process. The sintered ceramics can be further machined, ground or polished to obtain the desired surface finish and meet the most precise dimensional tolerances.

Equipment used in ceramic manufacturing

Typical ceramic manufacturing equipment includes storage containers, milling machines, industrial presses or casting machines, drying stations, glazers, sintering furnaces, and inspection stands.

Industrial ceramic tubes have the following advantages over traditional ceramics:

(1) Industrial ceramic tubes have phase change toughening and micro-crack toughening, so they have high strength and toughness, known as "ceramic steel", and its fracture toughness is the highest in all ceramics.

(2) Industrial ceramic tubes have excellent room temperature mechanical properties. On this basis, we optimize the formula and process of zirconia, and obtain high hardness, high strength and high toughness zirconia ceramics with fine crystal structure. High hardness, high strength and high toughness ensure that zirconia ceramics have incomparable wear resistance than other traditional structural ceramics.

(3) Industrial ceramic tube ceramics with fine crystal structure can obtain very low surface roughness through processing. Therefore, the friction coefficient of the ceramic surface is reduced, thus reducing the magic friction force and improving the quality of the drawing (the pulled silk is smooth and burr free, and it is not easy to break the wire).

Application fields and characteristics of ceramic tubes

Mechanical field

Ceramic tubes are used as pipes in the mechanical field and are commonly found in particle delivery and infusion systems. It has excellent hardness and wear resistance, can withstand the impact and wear of particles well, and can effectively reduce the friction loss of the pipeline. Therefore, in the field of strong wear and corrosion, ceramic tubes have replaced traditional metal tubes and are widely used in equipment for conveying wear materials.

Electronic field

Ceramic tubes are widely used in the field of electronics, especially in the manufacture of electronic components play an important role. Its chemical stability is high, it is not easy to be corroded by chemical substances, and can be used as the shell and bracket of electronic components. In addition, ceramic tubes can also be used for welding, packaging and support of high-frequency electronic components.

Chemical industry field

Ceramic pipe in the chemical industry is mainly used as corrosion resistance, high temperature resistant pipes, valves, pumps and other components, its advantages are able to withstand acid and alkali, high temperature and high pressure and other harsh environment, while with good sealing, wear resistance and other characteristics, is widely used in chemical industry, petroleum, fertilizer, metallurgy and other industries.

Precision of manufacture | |

Dimensional accuracy | Up to 0.001mm |

Smoothness | Highest possible mirror |

Concentricity | Up to 0.003mm |

Parallelism | Up to 0.002mm |

The inner hole tolerance | The minimum 0.005mm |

Straight flute | The narrowest 0.1x100mm |

The thickness of the size | Minimum to 0.02mm |

The screw thread | Minimum internal thread M2 |

Cylindricity | Up to 0.004mm |

The linear tolerance | Up to 0.001mm |

The smallest aperture | The minimum 0.07mm |

Precision process | CNC maching,grinding,lapping |

Surface finish | Glazed,polishing or metallized |

Visual quality: | |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.