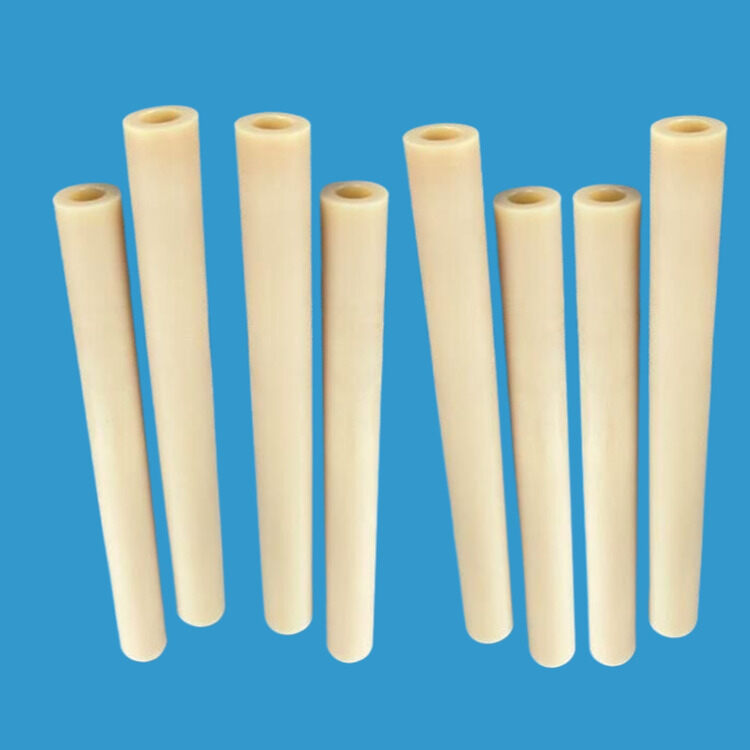

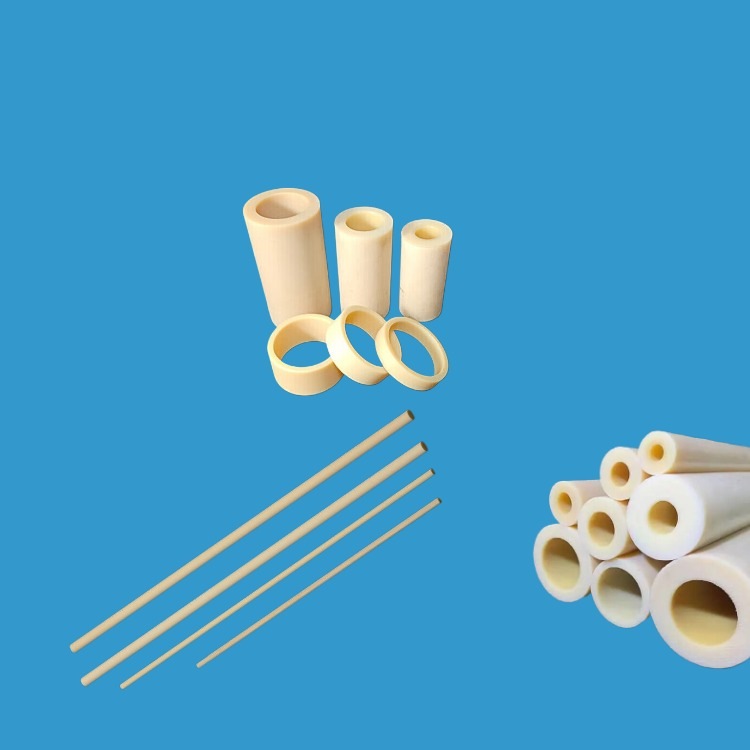

Customized alumina ceramic tube high purity al2o3 machinable aluminum oxide ceramic tubes

Ceramic materials are available:Alumina (Al2O3) 95% to 99.99% ...etc

General sizes:Outer diameter up to 60mm; The maximum length is 410mm...

Delivery times:2 -25 days(depends on the quantity)

Hole dimension accuracy: 0.10mm;

Hole shape accuracy: 0.05mm;

Features:high strength and high hardness,Good wear-resistant, Good tensile strength...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

As a kind of high strength and high hardness ceramic material, alumina ceramic tube has been widely used in many fields. Due to its excellent performance and durability, alumina ceramic tubes can still maintain stable performance in harsh environments such as high temperature, high pressure and corrosion.

Customize processes of alumina ceramic tube

Demand confirmation

Design drawing

Material made

Processing and production

According to the drawing, CNC machining, stamping, polishing, grinding and other work can produce alumina ceramic tube with specific shape, size and performance. The processing and production links need to be managed and controlled on site to ensure the quality of alumina ceramic tube and avoid unnecessary loss and waste.

Quality inspection

Common machining for alumina ceramic tube

Grinding processing: Grinding processing is the most commonly used method in the processing of ceramic materials, mainly used to remove excess materials on the surface of ceramic, improve surface quality and accuracy. Grinding can be divided into cylindrical grinding, internal grinding, surface grinding, crankshaft grinding and so on.

Laser processing: Laser processing is a method of cutting, drilling, engraving and other processing of ceramic materials using the high energy density of laser beams. Laser processing has the advantages of fast processing speed, small heat affected zone and high processing accuracy.

CNC milling: CNC milling is a method of machining precision parts using CNC machine tools. CNC milling can be used to remove excess material from ceramic surfaces and can also be used to process complex shapes.

Customized service of alumina ceramic tube

Customized ceramic materials are: alumina ceramic al2o3 purity: 95%,97%,98%,99%

Customizable ceramic tube shapes are: concentric round; Oval shape; Square; Porous shape, etc.

Customizable machining types: drilling, threading, welding, pasting, inner teeth, flanges, etc.

Machining accuracy: accuracy ±0.005

Properties of alumina ceramic tubes

Alumina ceramic tube has the characteristics of high strength, high hardness, high temperature resistance, corrosion resistance and so on. Its bending strength and fracture toughness are better than metal materials, can work stably at high temperatures for a long time, and has excellent insulation and heat insulation properties. In addition, alumina ceramic tube also has good chemical stability, not easy to react with acid, alkali and other media, suitable for a variety of harsh environmental conditions.

Alumina ceramic tube application field

Alumina ceramic tube has a wide range of applications because of its excellent performance. In the chemical industry, it can be used to manufacture pipes, valves, reactors and other chemical equipment; In the field of power, it can be used to manufacture high temperature flue gas filters, thermocouple bushings, etc. In the aerospace field, it can be used to manufacture high temperature parts such as nozzles and combustion chambers; In the field of metallurgy, it can be used to manufacture high temperature furnace tubes. With the continuous development of science and technology, the application prospects of alumina ceramic tubes will be broader.

Alumina ceramic tube size specifications

ID(mm) | OD(mm) | Length(mm) |

5 | 7 | 55 |

53 | 55 | 152 |

36 | 38 | 28 |

54 | 56 | 103 |

4 | 6 | 118 |

56 | 58 | 45 |

46 | 48 | 109 |

23 | 25 | 100 |

31 | 33 | 107 |

32 | 34 | 86 |

53 | 55 | 140 |

24 | 26 | 130 |

24 | 26 | 142 |

7 | 9 | 187 |

54 | 56 | 140 |

25 | 27 | 190 |

11 | 13 | 185 |

20 | 22 | 134 |

25 | 27 | 67 |

41 | 43 | 81 |

58 | 60 | 43 |

22 | 24 | 176 |

8 | 10 | 120 |

60 | 62 | 73 |

44 | 46 | 191 |

58 | 60 | 113 |

59 | 61 | 141 |

14 | 16 | 202 |

58 | 60 | 128 |

13 | 15 | 64 |

51 | 53 | 184 |

46 | 48 | 36 |

16 | 18 | 33 |

4 | 6 | 147 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.