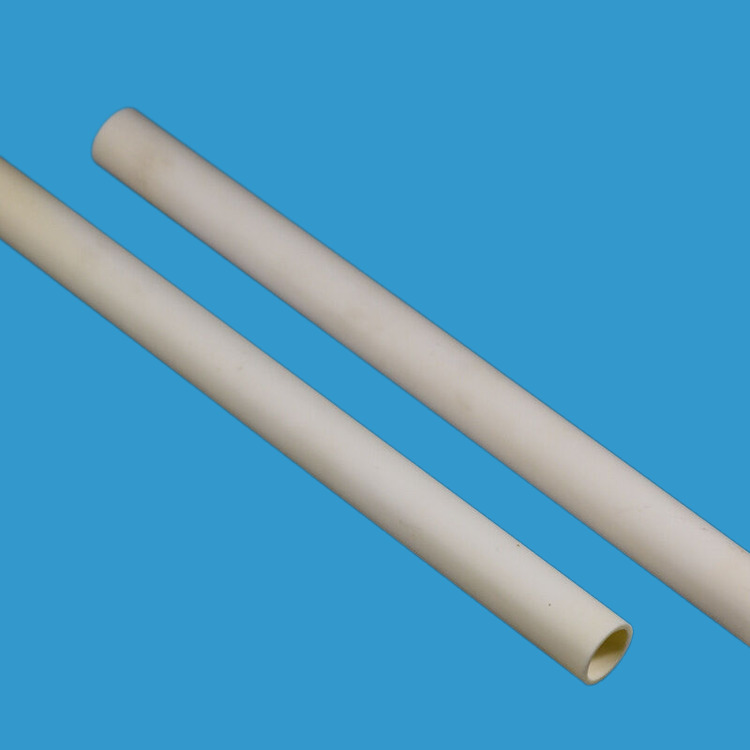

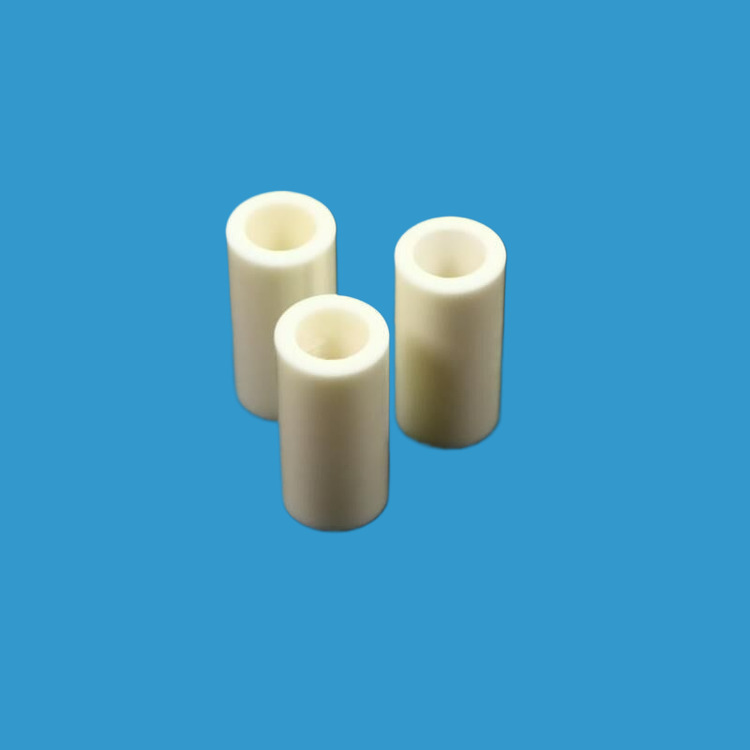

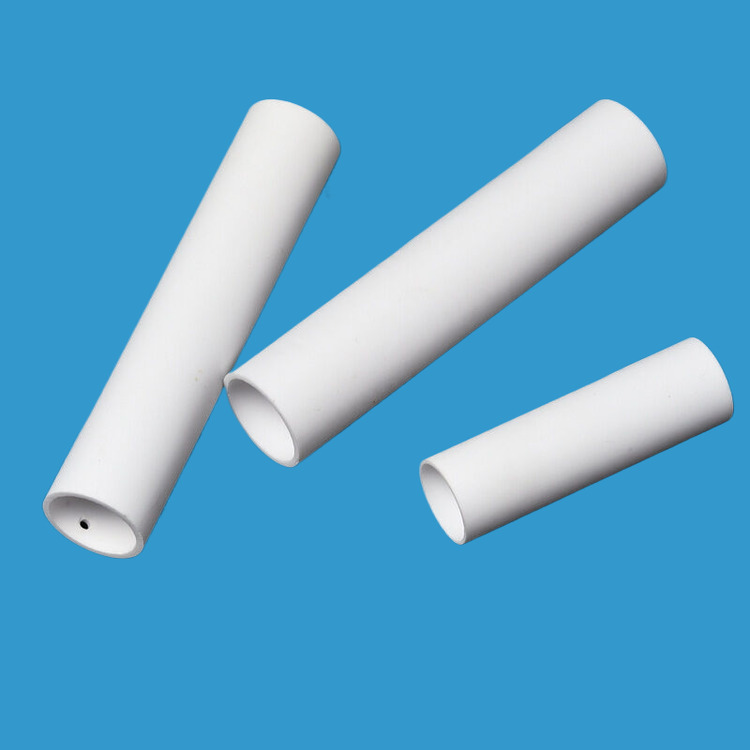

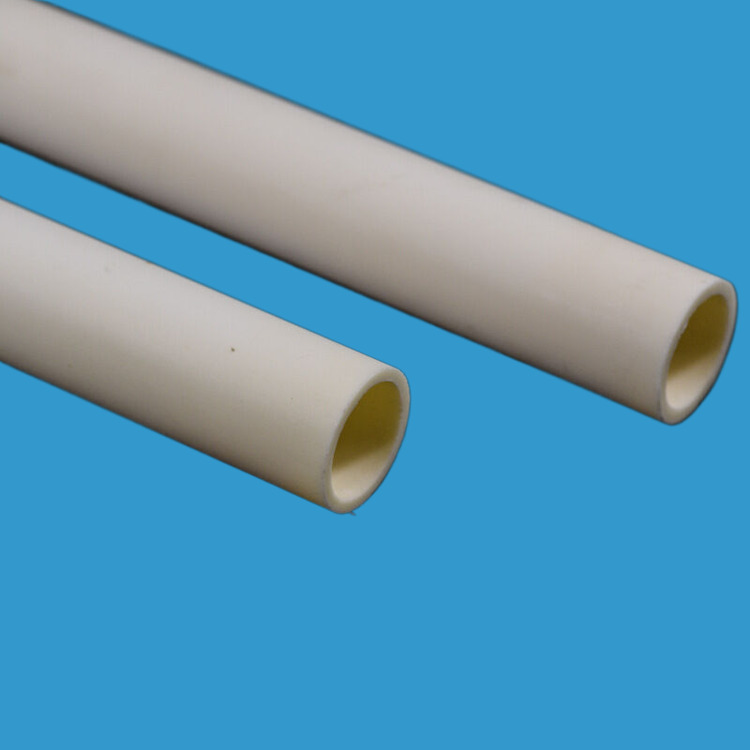

High temperature ceramic tube high heat anti al2o3 alumina insulation Low expansion zirconia tubes

Standard specification: Outer diameter is 3mm-120mm, wall thickness is 0.5mm-10mm.

Customized specifications: Customized according to customer

requirements, diameter, length, thickness and other parameters can be

customized according to different application scenarios and

requirements.

Factors to consider when purchasing

Temperature range: from 300 ° C to up to 2000 ° C.

Size: The appropriate size specifications should be selected according to the actual use needs, or customized.

Pressure resistance: Select ceramic tubes with appropriate pressure

resistance according to the specific application scenario.

Drilling

processing: accuracy 0.01-- 0.1mm; Surface machining: accuracy 0.002mm;

Cylindrical processing: accuracy 0.002mm; Inner circle processing:

accuracy 0.005mm; Polishing: Accuracy 0.005mm.

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

The high-temperature temperature range of ceramic tubes is generally between 1000 ° C and 1700 ° C, and the high-temperature ceramic tubes can be selected to be made of inorganic non-metallic materials with high melting point such as aluminum oxide, zirconia and silicon oxide.

High temperature resistance ceramic tube temperature

The temperature range of high temperature resistant ceramic tubes can be from 300 ° C to up to 2000 ° C.

The temperature range of high temperature resistant ceramic tubes varies with different materials and processes. Common ceramic materials such as alumina (Al2O3) ceramic tubes, can withstand temperatures up to 1700°C to 2000°C. This kind of ceramic tube is usually made by self-burning high temperature coupling synthesis method . The structure of the tube is composed of corundum ceramic, transition layer and steel layer from inside to outside respectively. has good wear resistance, heat resistance, corrosion resistance and mechanical and thermal shock resistance. In addition, sintering process also has remarkable effect on the temperature resistance of ceramic tube, generally, the temperature resistance of sintered ceramics is about 900℃.

High temperature insulating ceramic is a kind of high temperature resistant ceramic, because of its high temperature resistance and is widely used in mechanical equipment.

High temperature insulated ceramic tube beautiful

High temperature insulated ceramic tube after firing, can use the engraving machine ceramic processing shape, fine engraving pattern and not easy to be damaged, such a ceramic tube beautiful and generous.

high temperature insulation ceramic tube anti-static

High temperature insulated ceramic tubes are made of zirconia alumina, which is proven to be an anti-static material unless low electrical conductivity is achieved to a certain extent.

5, high temperature insulation ceramic tube resistance to scratch

The surface structure of the high temperature insulated ceramic tube is finished, so that the ceramic tube is not easy to be damaged under the action of external hard objects, and the ceramic tube has strong anti-beating ability.

Common specification

1. Standard specification: Outer diameter is 3mm-120mm, wall thickness is 0.5mm-10mm.

2. Customized specifications: Customized according to customer requirements, diameter, length, thickness and other parameters can be customized according to different application scenarios and requirements.

Factors to consider when purchasing

1. Temperature range: Select a ceramic tube with an appropriate temperature range based on the actual application scenario.

2. Size: The appropriate size specifications should be selected according to the actual use needs, or customized.

3. Pressure resistance: Select ceramic tubes with appropriate pressure resistance according to the specific application scenario.

Drilling processing: accuracy 0.01-- 0.1mm; Surface machining: accuracy 0.002mm; Cylindrical processing: accuracy 0.002mm; Inner circle processing: accuracy 0.005mm; Polishing: Accuracy 0.005mm.

| Length Range | Length Range | Outside Diameter | Outside Diameter | Inside Diameter | Inside Diameter |

| 6.876-12.875 in | 175-327 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.156 in | 3.96 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 6.876-12.875 in | 175-327 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.047 in | 1.19 mm |

| The size of the table above is the conventional ceramic tube parameters. We support the processing and customization of ceramic tubes with different parameters | |||||

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.