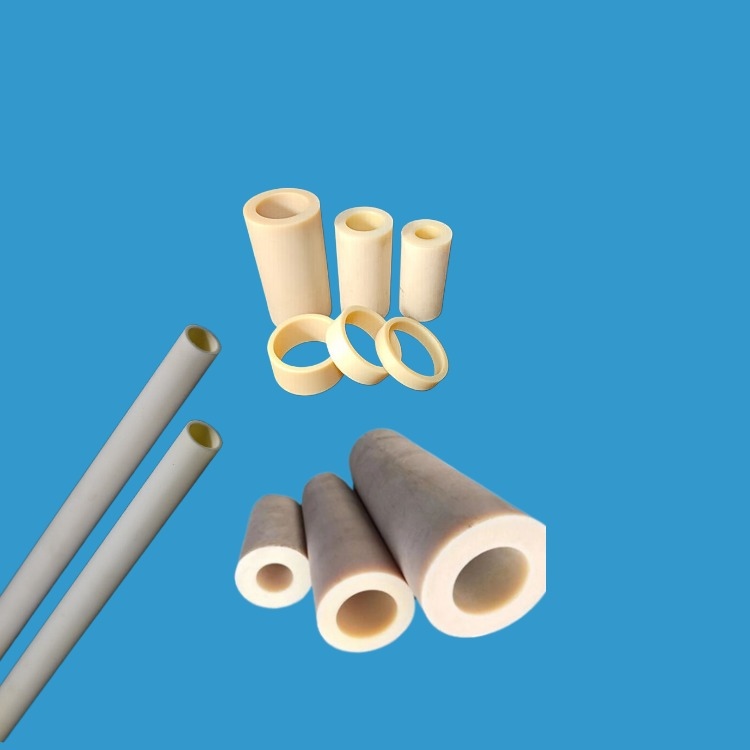

Industrial ceramic tube different types sizes of alumina zirconia ceramic tubes

Ceramic materials are available:alumina zirconia ceramic ...etc

Outer diameter :10-50mm

Wall thickness :1.0-20.0mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um

Thickness tolerance is ±0.02

Features:Wear resistance / High Corrosion / Good Insulation/Heat resistance...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Industrial ceramic tubes (also known as engineering ceramic tubes or high-performance ceramic tubes) often contain more complex compounds, including alumina ceramic tubes, carbide ceramic tubes, nitride ceramic tubes, boride ceramic tubes and zirconia ceramic tubes. Industrial ceramic tubes can obtain certain engineering characteristics or specific combinations of several characteristics under different formulations or processes, so that they can often replace metals, polymers and refractories in a variety of applications.

Because industrial ceramic tubes are usually exposed to harsh environments, such as high temperature, high pressure, corrosive substances, etc., their surface treatment needs to have higher corrosion resistance and wear resistance.

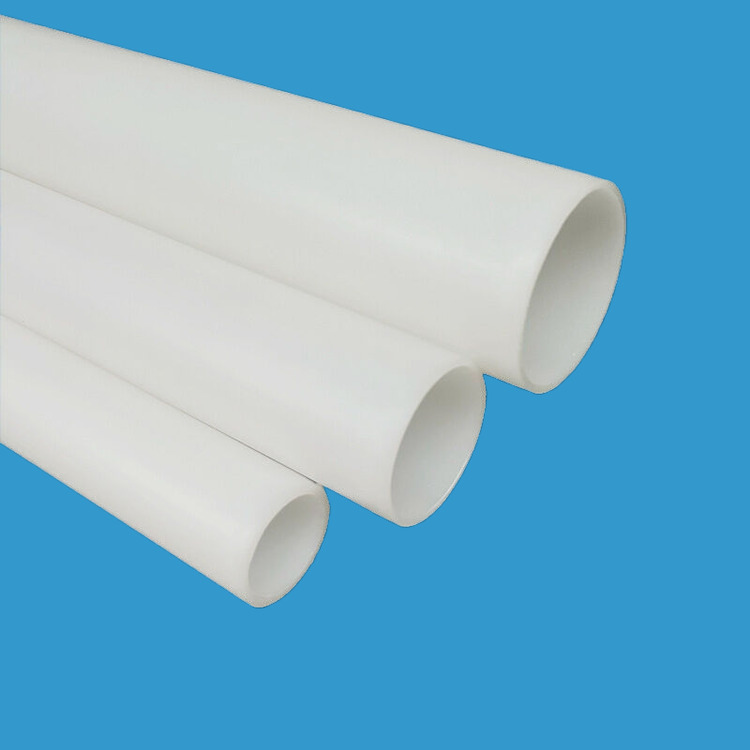

Industrial ceramic tubes are mainly used in factories, power stations, construction and agriculture and other places to transmit fluids such as water, gas, oil or chemicals. They need to withstand high pressure, high temperature and corrosive environments, so the material of industrial ceramic tubes is usually tougher and more durable.

General sizes of industrial ceramic tube

Outer diameter :10-50mm

Wall thickness :1.0-20.0mm

Other sizes available upon request. Other sizes available upon request.

Application: Structural industrial ceramic tube is widely used in chemical, petroleum, textile, medical, food, machinery and other industries of corrosion resistant tubes and structural parts and parts made of ceramic industrial ceramic tube.

Industrial ceramic tube tolerances

The outer diameter tolerance of the industrial ceramic tube can be controlled at +0.05, the thickness tolerance is ±0.02, and the length is +5mm: the outer diameter is accurate and the surface is smooth.

Industrial ceramic tube accuracy

Its features include high-precision tubes with an outer diameter limit deviation of ±0.02mm, an inner diameter limit deviation of ±0.025mm, and an inner hole circumference tolerance of 0.020mm. The outer diameter ranges from 8mm to 60mm, the wall thickness ranges from 0.4mm to 0.9mm, and the length of the steel tube ranges from 1.5mm to 6.0mm.

Characteristics of industrial ceramic tubes

The industrial ceramic tube is a kind of tubular material made by molding, sintering and other processes with clay as the main raw material. Its structural characteristics are as follows:

1. High wear resistance: The ceramic surface of the ceramic tube is very hard, so it has high wear resistance. Especially in the high-speed fluid environment, it has a longer service life than ordinary metal tubes.

2. High temperature corrosion resistance: Ceramic tubes can withstand the erosion of high temperature, high pressure and strong corrosive media, and its corrosion resistance can meet the needs of many special industrial conditions.

3. Excellent insulation performance: The insulation performance of ceramic tubes is very good, which can effectively isolate the electrodes between the medium and avoid the occurrence of leakage and fire.

Industrial ceramic tube sizes chart

OD(mm) | ID(mm) | Length(mm) |

67 | 65 | 84 |

67 | 65 | 75 |

46 | 44 | 55 |

54 | 52 | 56 |

72 | 70 | 89 |

18 | 16 | 61 |

49 | 47 | 82 |

58 | 56 | 86 |

9 | 7 | 91 |

60 | 58 | 52 |

40 | 38 | 67 |

37 | 35 | 89 |

37 | 35 | 61 |

13 | 11 | 473 |

61 | 59 | 232 |

70 | 68 | 372 |

52 | 50 | 542 |

72 | 70 | 285 |

57 | 55 | 543 |

23 | 21 | 189 |

20 | 18 | 149 |

78 | 76 | 383 |

50 | 48 | 307 |

52 | 50 | 644 |

37 | 35 | 159 |

58 | 56 | 294 |

55 | 53 | 119 |

9 | 7 | 48 |

47 | 45 | 97 |

23 | 21 | 343 |

47 | 45 | 22 |

11 | 9 | 348 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.