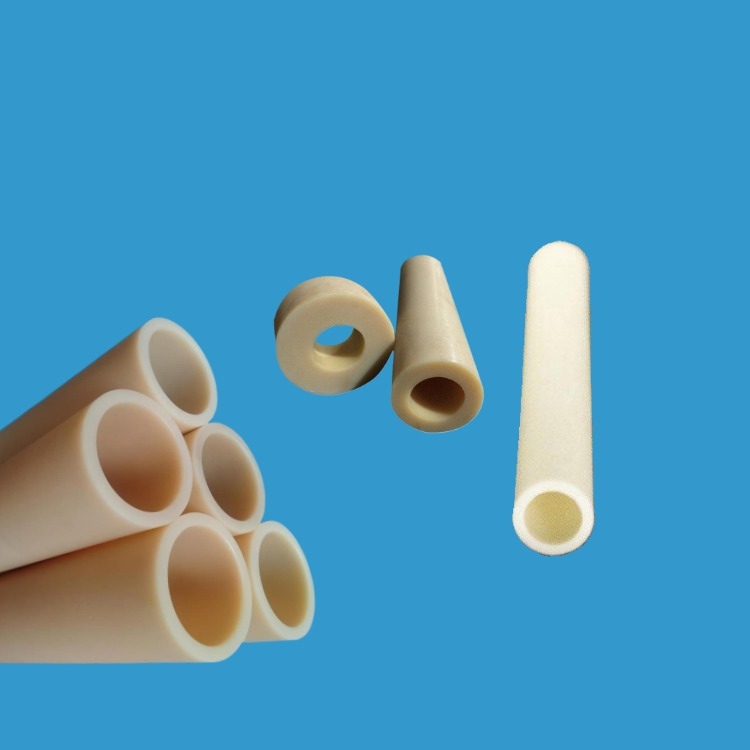

Metalization ceramic tube high mechanical strength and bonding strength ceramic tubes

Ceramic materials are available:metalization ceramic ...etc

General sizes:length max up to 600mm...

Delivery times:2 -25 days(depends on the quantity)

Hole position accuracy: 0.02mm;

Hole roughness: Ra3.2-0.8;

Features:High mechanical strength and bonding strength...

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

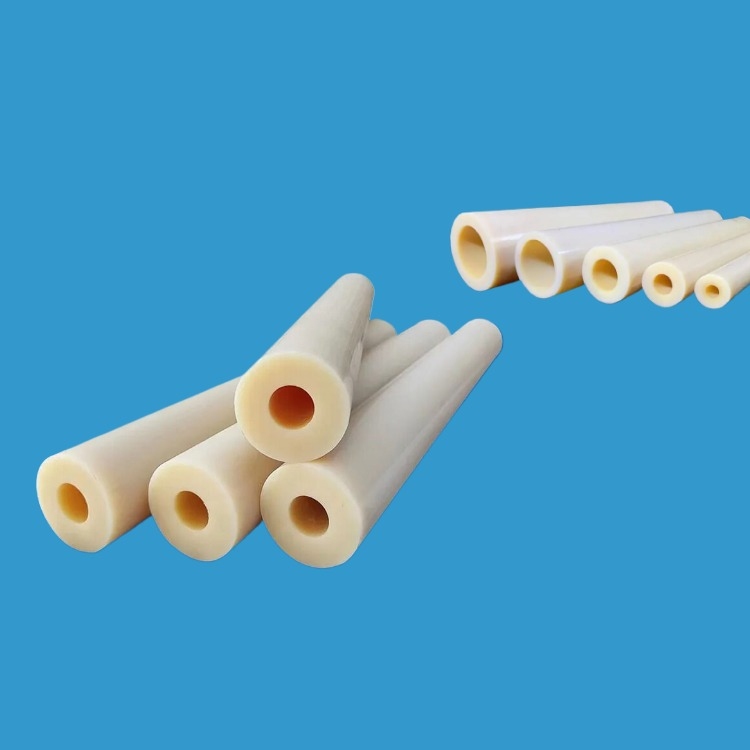

Metallized ceramic tube is a kind of tube made of ceramic tube coated with metal layer and then sintered at high temperature. The main principle is to combine the excellent electrical properties of ceramics with the excellent electrical conductivity of metals to achieve a material with superior performance. Metallized ceramic tube not only has excellent electrical insulation, capacitance and dielectric strength, but also has the advantages of high strength, wear resistance and corrosion resistance.

Metallized ceramic products, products are widely used in microwave porcelain control tube, gas discharge tube, electric vacuum device, etc., with good air tightness in high vacuum environment, high insulation strength, good mechanical strength and so on. Ceramic metallization can be carried out on flat, cylindrical or complex shaped ceramic products through processes such as jet, brush or screen printing. In metallized ceramics, alumina ceramics are usually used as the tube material, the ceramics are coated with molybdenum manganese or tungsten manganese bottom layer, and then coated with a layer of nickel layer, the metal layer and the ceramic layer are well combined together, so that the metallized ceramics can be welded, packaging and other processing.

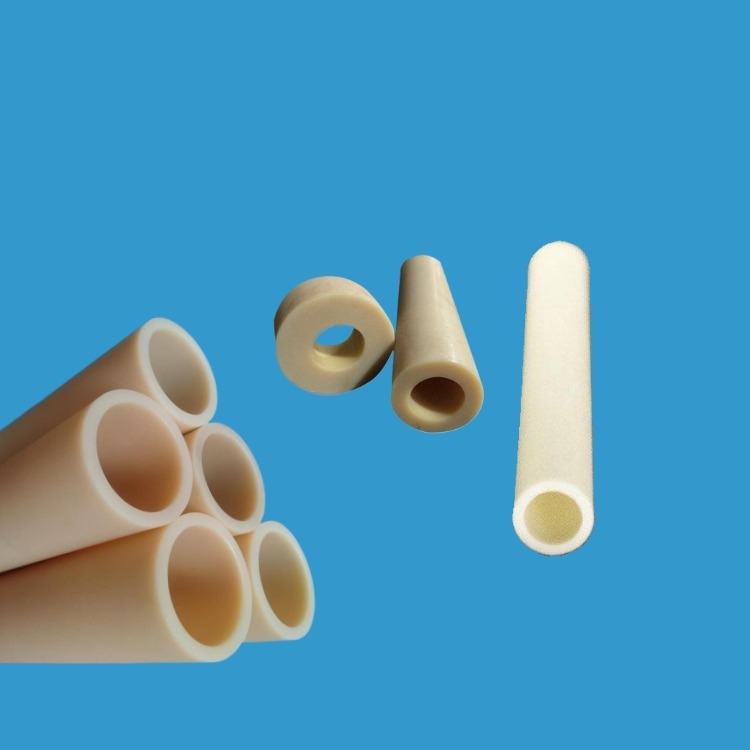

Features of metallized ceramic tubes

- High mechanical strength and bonding strength

- Good thermal stability

- High pressure resistance

- Vacuum seal is good

- Excellent weldability

Metallized layer

Bottom layer: tungsten or molybdenum layer

The ceramic tube material is first coated with a layer of tungsten or molybdenum, the coating thickness depends on the shape of the product and the brushing process, the general coating thickness can reach 6 μm, and then sintering curing.

Nickel layer

The bottom layer is generally coated with a 0.5-5μm thick layer of nickel, and other coatings such as gold, copper or tin are also feasible.

Advantages of metallized ceramic tubes

l 1.Excellent electrical properties

metallized ceramic tubes have excellent electrical insulation, capacitance and dielectric strength, which can effectively protect electronic equipment from electric shock and electromagnetic interference.

l 2. High strength, wear resistance and corrosion resistance

The metal layer of the metallized ceramic tube has the advantages of high strength, wear resistance and corrosion resistance, and can maintain stable performance in harsh environments.

l 3. Good electrical conductivity

The metal layer of the metallized ceramic tube has excellent electrical conductivity, which can improve the transmission efficiency and speed of the pipe.

l 4. Easy processing

metallized ceramic tubes can be customized according to user requirements and are easy to process and install.

Application fields of metallized ceramic tubes

1. Power field: metallized ceramic tubes are widely used in high-voltage power equipment such as transformers, fuses, circuit breakers to protect electronic equipment from electric shock and electromagnetic interference.

2. Mechanical field: metallized ceramic tubes can be applied to the transmission system, bearings and other parts of mechanical equipment to improve the transmission efficiency and speed of mechanical equipment.

3. Chemical industry: metallized ceramic tubes can be used in reactors, storage tanks, pipelines and other parts of chemical equipment to improve the corrosion resistance and stability of chemical equipment.

4. Metallurgical field: metallized ceramic tube can be applied to the converter, blast furnace, hot metal pot and other parts of metallurgical equipment to improve the high temperature and high pressure resistance of metallurgical equipment.

In summary, metallized ceramic pipe is a kind of pipe with excellent electrical properties, high strength and wear resistance, which is widely used in electric power, machinery, chemical industry, metallurgy and other fields.

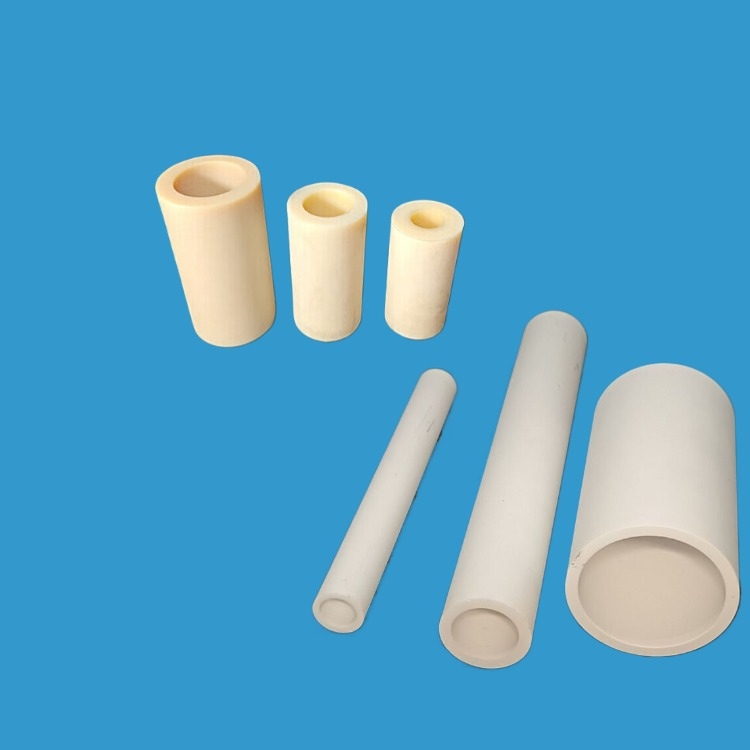

Metalization ceramic tube sizes chart

ID(mm) | OD(mm) | Length(mm) |

44 | 46 | 172 |

29 | 31 | 38 |

7 | 9 | 45 |

21 | 23 | 22 |

33 | 35 | 35 |

29 | 31 | 34 |

43 | 45 | 22 |

26 | 28 | 25 |

26 | 28 | 43 |

25 | 27 | 46 |

29 | 31 | 43 |

43 | 45 | 8 |

42 | 44 | 33 |

26 | 28 | 49 |

49 | 51 | 16 |

50 | 52 | 9 |

40 | 42 | 39 |

44 | 46 | 28 |

19 | 21 | 34 |

38 | 40 | 11 |

13 | 15 | 7 |

33 | 35 | 13 |

46 | 48 | 30 |

41 | 43 | 26 |

31 | 33 | 33 |

24 | 26 | 41 |

50 | 52 | 19 |

32 | 34 | 22 |

24 | 26 | 47 |

14 | 16 | 7 |

51 | 53 | 184 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.