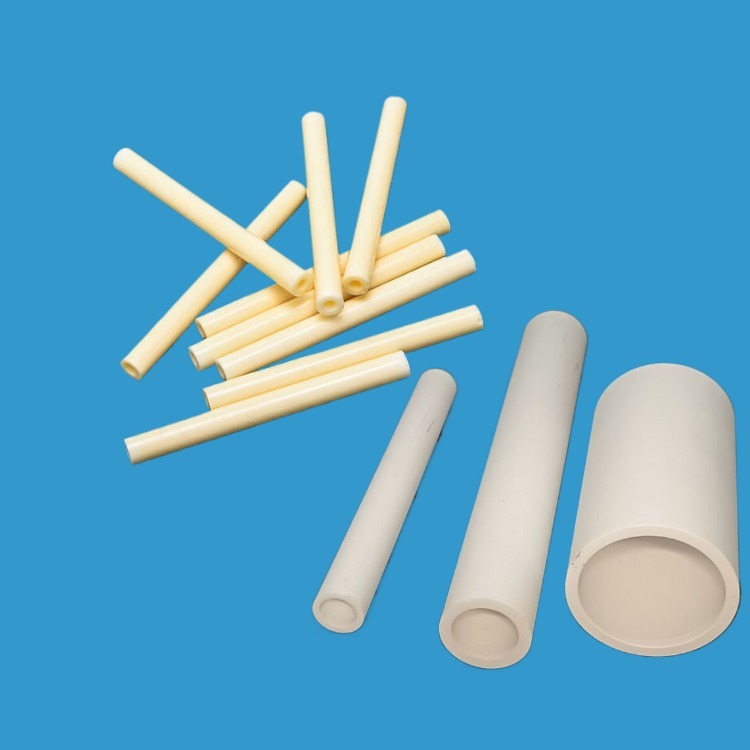

Small diameter ceramic tubes small holes types ceramic tube

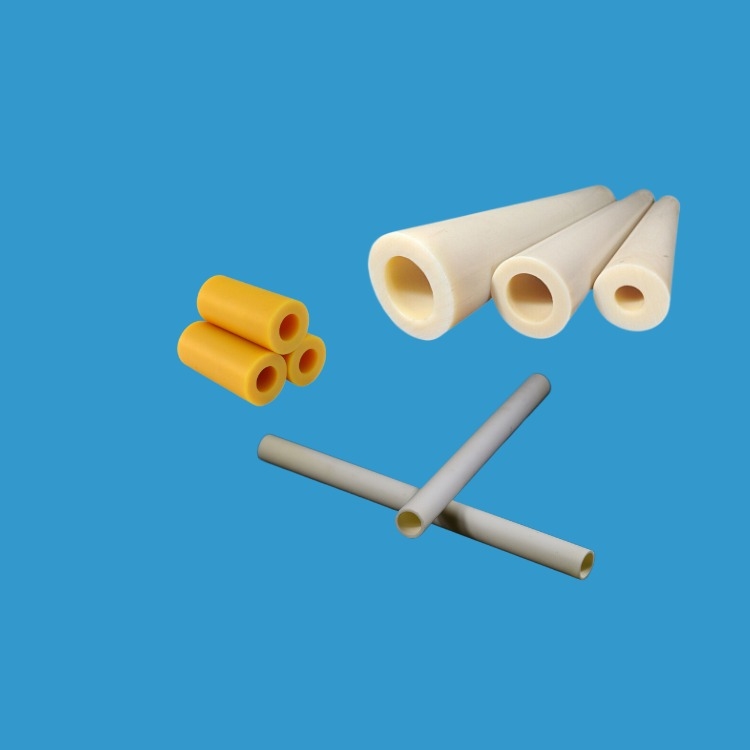

Ceramic materials are available:Alumina (Al2O3), zirconia (ZrO2), silicon oxide (SiO2) ...etc

General sizes:Outer diameter (mm) : 1.7-80

Precision:Ra 0.1um

Section shape: round tube, square tube

Features:High durability, strong corrosion resistance, long-term excellent performance....

Customized:Can be custom for special sizes and shapes

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Small diameter ceramic tube usually refers to the diameter or length of ceramic tube is very small, the length is usually in the range of 2mm - 100mm; Inner diameter in the range of 1mm-6mm; The outer diameter is in the range of 1.5mm - 8mm. Specific small parameters of the ceramic tube according to the actual use requirements.

Features of small ceramic tubes

Tolerance: 0.1mm

Customizable: Customizable

Processing method: mechanical processing

Outer diameter (mm) : 1.7-80

Wall thickness (mm) : 0.6-3

Length (mm) : 2-100

Section shape: round tube, square tube

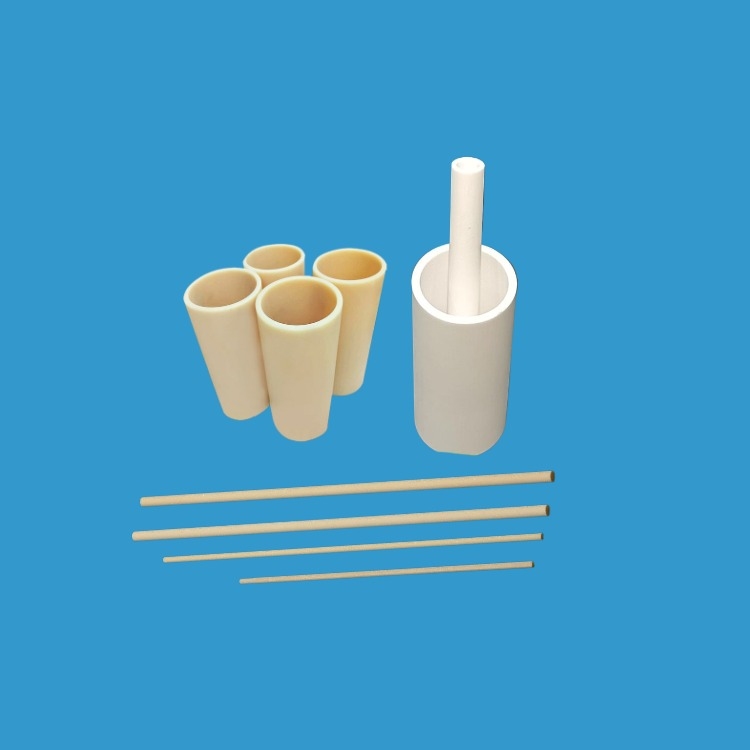

Small diameter ceramic tube is generally used for industrial sensors, electronic equipment line protection tube, automatic instrument signal tube, electrical line safety protection, automatic instrument wire protection tube, precision optical ruler line, thermal instrument capillary safety protection and hollow core high pressure optical cable internal support.

Properties of small diameter ceramic tube

+ High hardness

+ High mechanical strength

+ Superior wear resistance

+ Good chemical stability

+ High thermal conductivity

+ High temperature resistant

+ Good electrical insulation

+ Low dielectric constant

The specific applications of small diameter ceramic tubes

1, precision instrument: watch, tester.

2, temperature sensor probe shell: temperature sensor, infrared sensor, water level detector and so on.

3. Core tube, pen tube for pen making industry.

4, miniature antenna tube: laptop antenna stainless steel capillary, smart home antenna and so on.

5, all kinds of electronic micro, small diameter stainless steel capillary

6, also suitable for small freon refrigeration equipment below 10kW. After the installation of small diameter ceramic tube can not change with the load change, in order to make the refrigeration equipment in most of the time to operate efficiently, choose a representative design conditions is extremely important.

Small diameter ceramic tube sizes chart

OD(mm) | ID(mm) | Length(mm) |

10 | 8 | 33 |

22 | 20 | 14 |

6 | 4 | 59 |

2 | 1 | 33 |

45 | 43 | 59 |

52 | 50 | 89 |

37 | 35 | 75 |

4 | 2 | 39 |

18 | 16 | 70 |

39 | 37 | 60 |

5 | 3 | 22 |

20 | 18 | 24 |

11 | 9 | 29 |

14 | 12 | 79 |

47 | 45 | 54 |

37 | 35 | 2 |

8 | 6 | 75 |

33 | 31 | 29 |

28 | 26 | 22 |

47 | 45 | 42 |

28 | 26 | 21 |

46 | 44 | 86 |

9 | 7 | 74 |

55 | 53 | 2 |

57 | 55 | 98 |

13 | 11 | 94 |

31 | 29 | 41 |

56 | 54 | 46 |

56 | 54 | 95 |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.