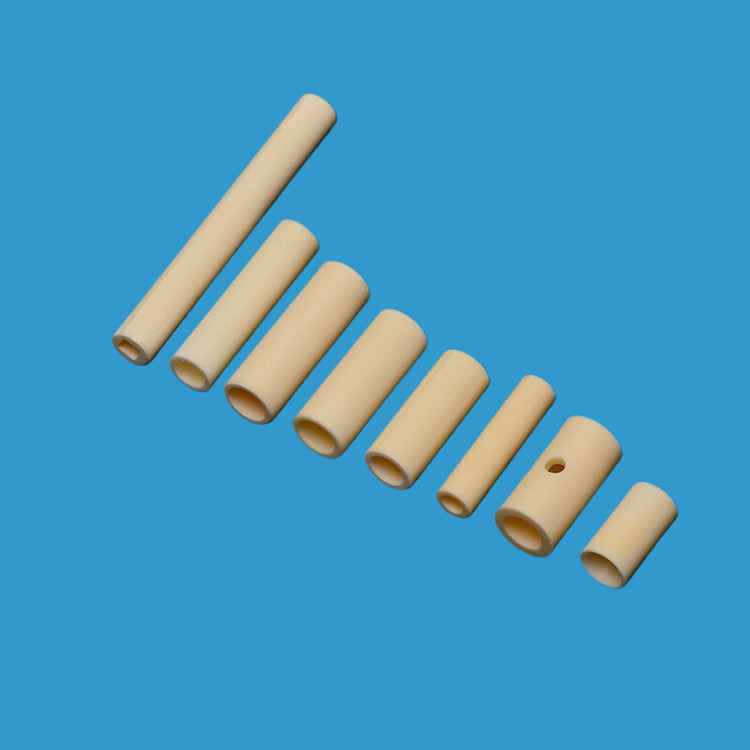

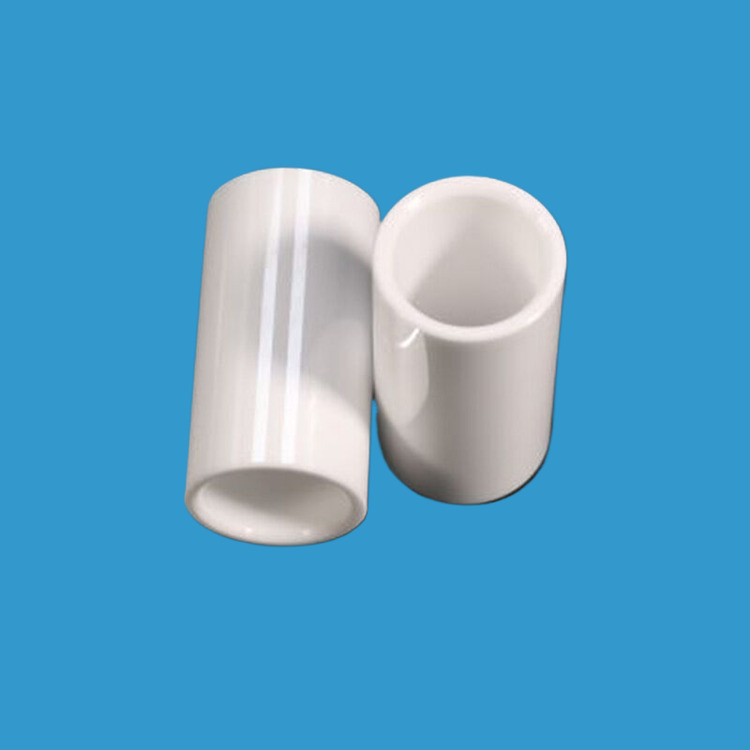

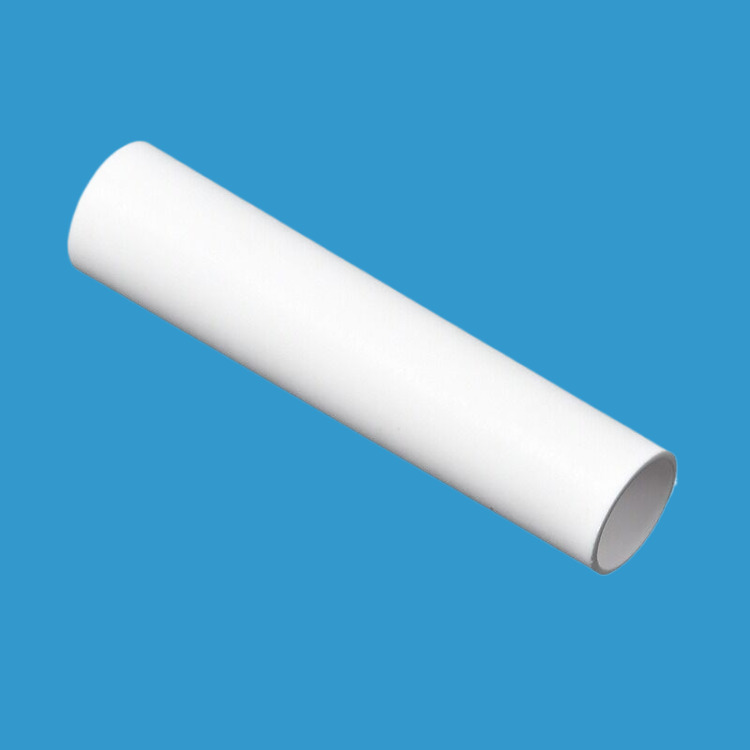

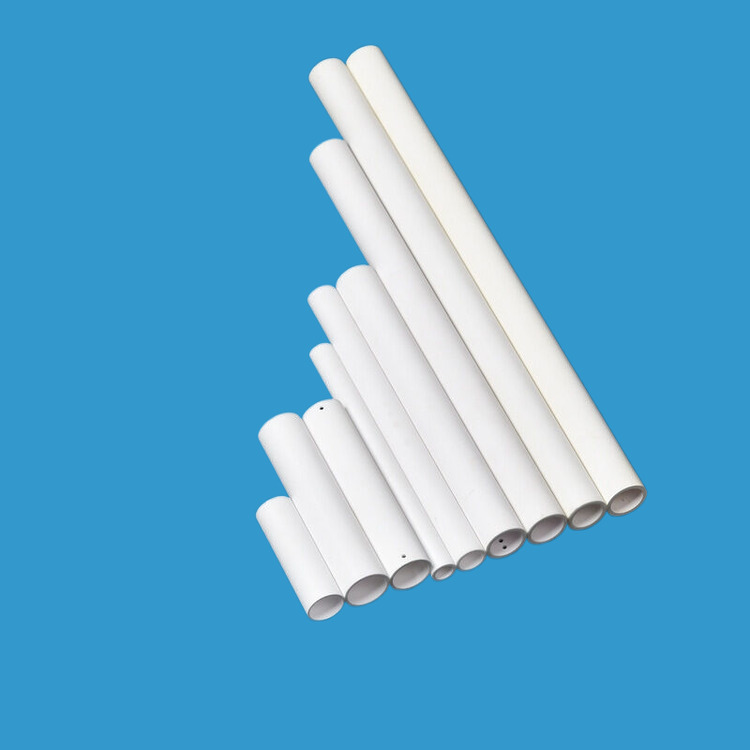

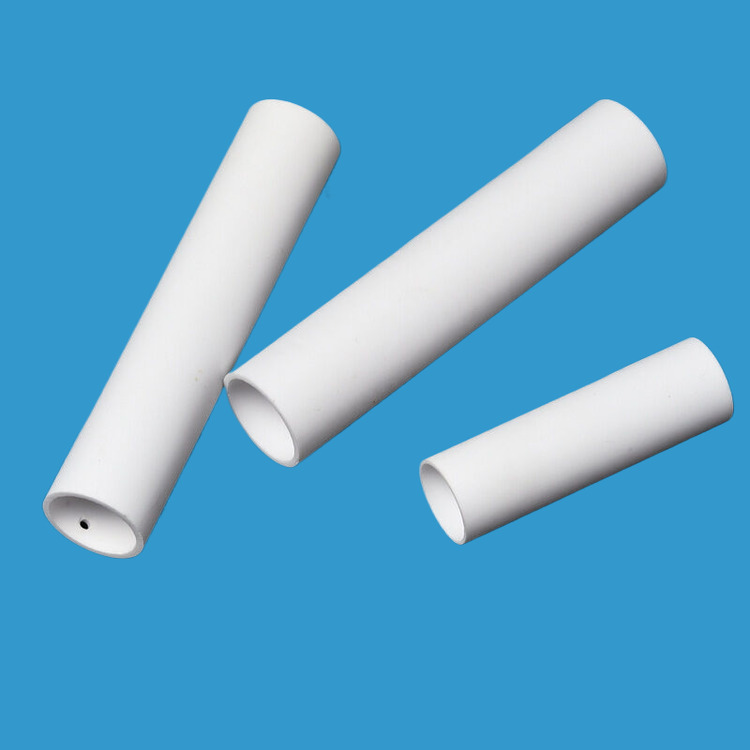

Wear resistant ceramic cone tube high hardness al2o3 alumina tube high strength zirconia tubes

Material range: zirconia, alumina material

Sizes: ID:0.5--145mm; OD:1--150mm; Length:3--500mm

Hole dimension accuracy: 0.10mm;

Hole shape accuracy: 0.05mm;

Hole position accuracy: 0.02mm;

Hole roughness: Ra3.2-0.8;

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

The wear resistance of the wear-resistant ceramic tube mainly depends on the wear resistance of the wear-resistant ceramic lining, and the wear resistance refers to the ability of the material to resist mechanical wear, mainly determined by the hardness, strength and roughness of the material.

1, hardness: the hardness of the material reflects the ability of the material to resist the material pressed into the surface, the higher the hardness of the material the shallower the depth of intrusion, the smaller the volume of wear, the higher the wear resistance. The alumina content of wear-resistant ceramics exceeds 92%, and the hardness reaches more than HRA85, which is the basis of wear-resistant ceramic tubes.

2, strength: high strength, can provide good support for the resistance to wear, give full play to the ability to wear hard resistance, that is to say, strength and hardness complement each other. The bending strength of grinding ceramics reaches 300-450mpa, and the compressive strength is as high as 1200-2500mpa, which further strengthens the wear resistance of wear-resistant ceramic tubes.

First, the use of wear-resistant ceramic tubes

1. Metallurgical industry

In the metallurgical industry, the gas, liquid and impurities under high temperature and pressure will cause greater wear and damage to the pipeline, and the wear-resistant ceramic pipe has high hardness, wear resistance, corrosion resistance and other characteristics, and is widely used in the metallurgical field to transport hot metal, molten steel, aluminum water, heavy oil and other high temperature fluid pipelines.

2. Power industry

Wear-resistant ceramic pipe in the power industry is mainly used to transport coal, ash, powder and other media, due to the high-speed flow and strong collision of the medium, easy to lead to wear and rupture of the pipeline, and wear-resistant ceramic pipe hardness and wear resistance are relatively high, can be a good protection from damage to the pipeline.

3. Chemical industry

Most of the media in the chemical industry are relatively acid, alkaline and corrosive, and ordinary metal pipes are easy to be corroded and worn in this case, affecting the stability and safety of transportation, so wear-resistant ceramic pipes are often used in the transportation of media in the chemical industry.

Second, the advantages of wear-resistant ceramic tubes

1. Excellent wear resistance: wear-resistant ceramic pipe has high hardness, which can not only effectively prevent and delay wear, but also self-healing and self-healing ability when subjected to severe impact or multiple wear.

2. Excellent corrosion resistance: wear-resistant ceramic pipe has good chemical stability, and can withstand most acid, alkali, salt and other corrosive media, with excellent chemical stability.

Material range: zirconia, alumina material

Sizes: ID:0.5--145mm; OD:1--150mm; Length:3--500mm

Hole dimension accuracy: 0.10mm;

Hole shape accuracy: 0.05mm;

Hole position accuracy: 0.02mm;

Hole roughness: Ra3.2-0.8;

| Length Range | Length Range | Outside Diameter | Outside Diameter | Inside Diameter | Inside Diameter |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.047 in | 1.19 mm |

| 4.000-6.875 in | 102-174 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 12.876-18.875in | 328-479 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.000-6.875 in | 102-174 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.331-13.858 in | 110-352 mm | 0.205 in | 5.21 mm | 0.031 in | 0.79 mm |

| The size of the table above is the conventional ceramic tube parameters. We support the processing and customization of ceramic tubes with different parameters | |||||

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.