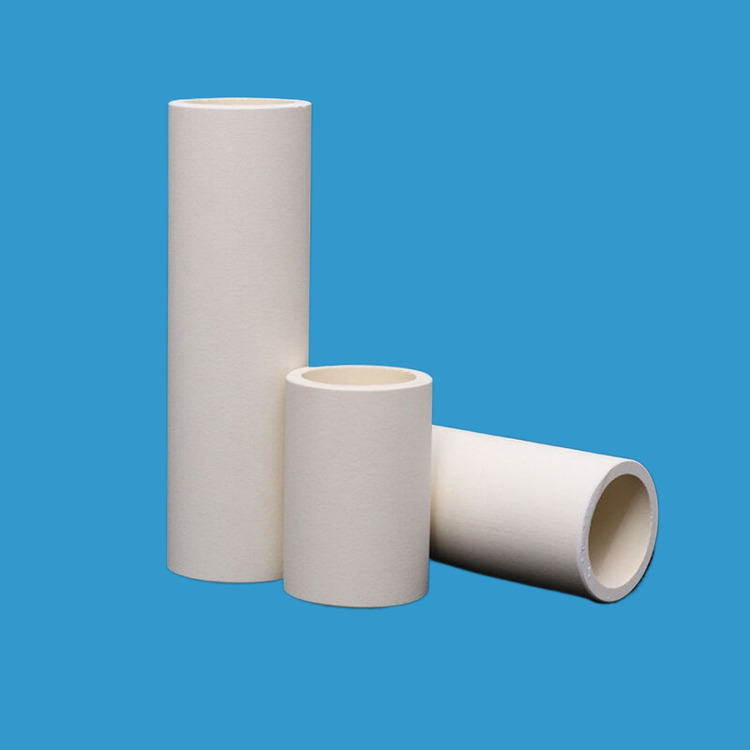

Zirconia ceramic tubes high mechanical strength and compression resistance zro2 ceramic tube

Material Service:

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

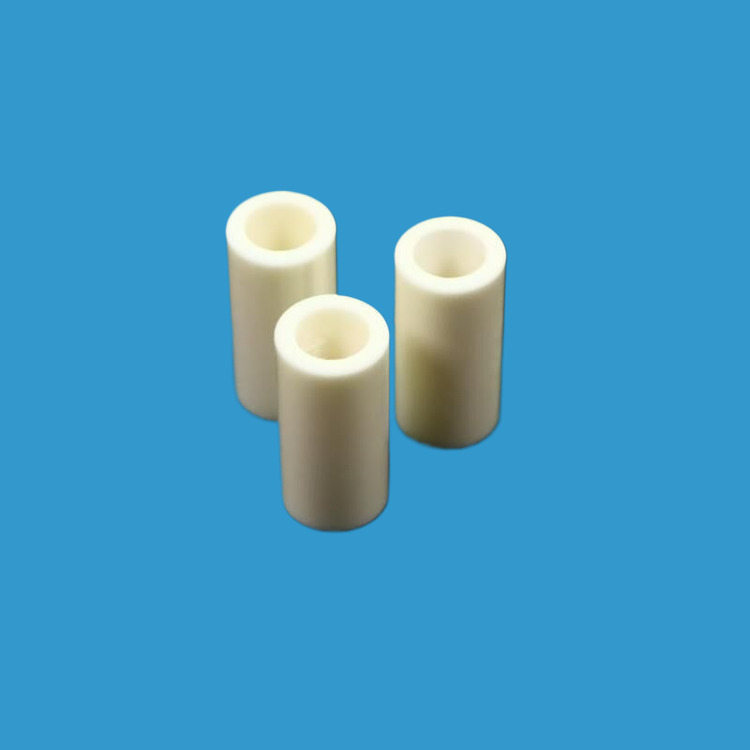

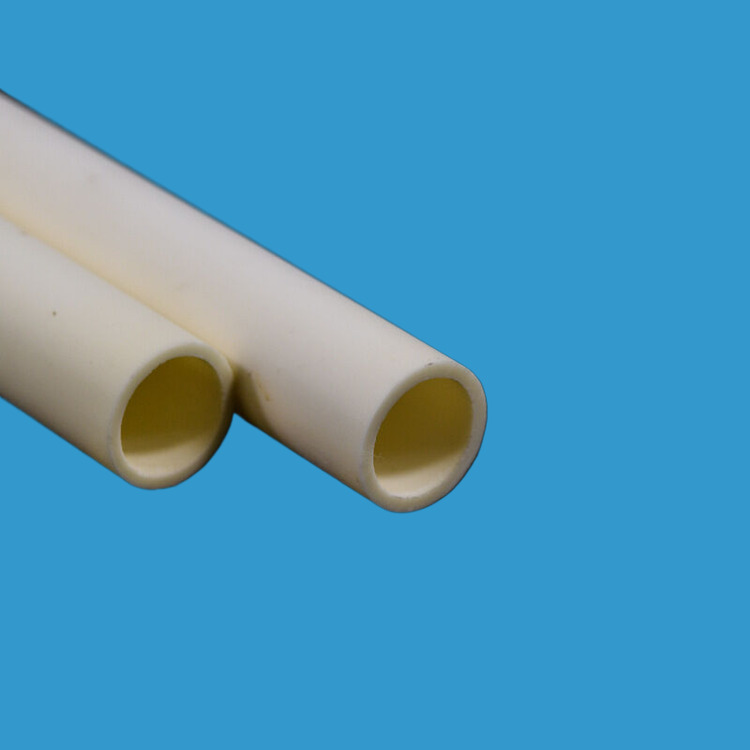

Zirconia ceramic tube cylindrical processing; Outer dimension: 0.01mm; Shape accuracy: 0.01mm; Roughness: Ra0.1 ~ 1.6;

Zirconia ceramic tube drilling processing

Material range: zirconia, hole size accuracy: 0.10mm;

Sizes:ID:0.5--145mm;OD:1--150mm;Length:3--500mm

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Zirconia ceramic is a new type of high tech ceramics, zirconia ceramic tube with phase change toughening and micro-crack toughening, zirconia ceramic tube has high strength and toughness, in all ceramics its fracture toughness is high.

Zirconia ceramic tubes have the advantages of high temperature stability, corrosion resistance, high hardness and wear resistance, good insulation, good biocompatibility, low thermal conductivity, high mechanical strength and environmental friendliness

Material Service:

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

Zirconia ceramic tube cylindrical processing; Outer dimension: 0.01mm; Shape accuracy: 0.01mm; Roughness: Ra0.1 ~ 1.6;

Zirconia ceramic tube drilling processing

Material range: zirconia, hole size accuracy: 0.10mm;

Advantages of zirconia ceramic tube:

High temperature stability: Zirconia ceramic tubes have excellent high temperature stability and can maintain the stability of their structure and performance at extremely high temperatures. This makes it ideal for use in high temperature environments, such as thermocouple protective tubes, molten metal filters, etc.

Corrosion resistance: Zirconia ceramic tubes have excellent corrosion resistance to most acids and bases. Even in highly corrosive environments, it maintains its performance and integrity, extending its service life.

High hardness and wear resistance: The hardness of zirconia ceramic tubes is very high, second only to diamond, so it is very wear-resistant. This characteristic makes it excellent in applications where wear resistance is required, such as as a grinding ball, dispersion and grinding medium.

Good insulation: Zirconia ceramic tube is an excellent electrical insulation material, its resistivity is very high. This allows it to have a wide range of applications in the electronics and electrical industry, such as as electronic components, sensors and semiconductor packaging materials.

Low thermal conductivity: Zirconia ceramic tubes have a low thermal conductivity, which means that it can be used as a thermal insulation material, reducing heat transfer and improving the thermal efficiency of the equipment.

High mechanical strength: Zirconia ceramic tubes have high mechanical strength and can withstand greater pressure and impact. This makes it excellent in applications where it is required to withstand mechanical stress, such as as a gas delivery pipe, filter, etc.

Inside diameter=ID Outside diameter=OD Length=L

ID 0.4mm*OD 1mm*L 100mm

ID 1mm*OD 2mm*L 100mm

ID 1.5mm*OD 3mm*L 100mm

ID 2mm*OD 3mm*L 100mm

ID 2mm*OD 4mm*L 100mm

ID 3mm*OD 5mm*L 100mm

ID 4mm*OD 6mm*L 100mm

ID 4mm*OD 8mm*L 100mm

ID 4mm*OD 10mm*L 100mm

ID 5mm*OD 7mm*L 100mm

ID 6mm*OD 8mm*L 100mm

ID 6mm*OD 9mm*L 100mm

ID 6mm*OD 10mm*L 100mm

ID 7mm*OD 11mm*L 100mm

ID 8mm*OD 12mm*L 100mm

ID 8mm*OD 16mm*L 100mm

ID 10mm*OD 13mm*L 100mm

ID 10mm*OD 14mm*L 100mm

ID 12mm*OD 16mm*L 100mm

ID 16mm*OD 20mm*L 100mm

ID 18mm*OD 25mm*L 100mm

ID 25mm*OD 32mm*L 100mm

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.