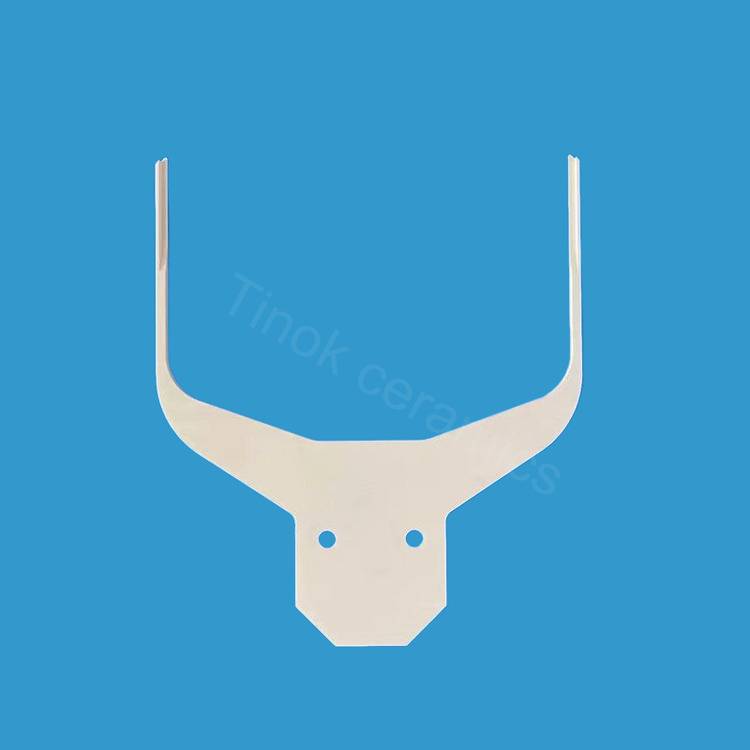

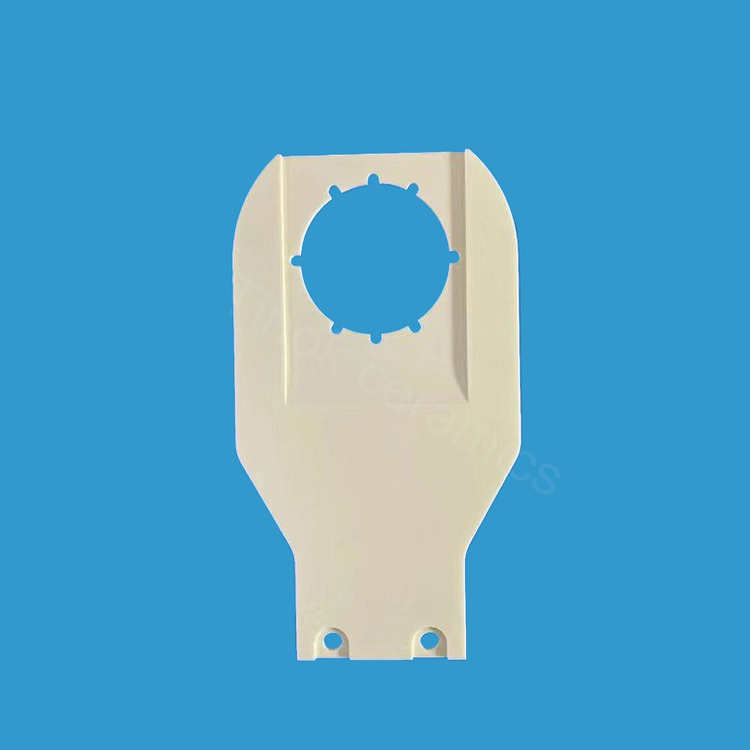

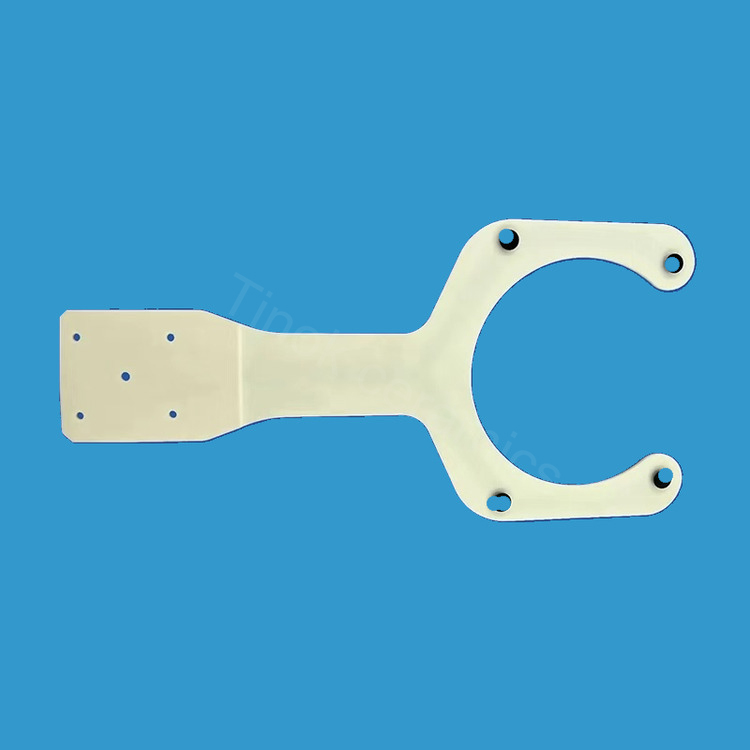

Custom semiconductor ceramic end effector high purity al2o3 alumina ceramic arm hand for semiconductor machine

Material:Alumina ceramic Purity

95%, 96%, 99%, 99.5%, 99.6%, 99.7%, 99.8%

Size:According to drawings or samples

Torlerance:+/- 0.01mm

Lead time:10-30 days

Delivery:Air Express (DHL/UPS/TNT/ FedEx)

Feature:High hardness, High strength, High temperacture

Max Working Temperature:1600℃

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Semiconductor ceramic end effector is used to grasp and clamp semiconductor parts, designed into a flat arm and palm, so as to absorb semiconductor parts, so as to achieve light contact, will not be hurt, will not hurt the semiconductor parts sheet, because of the ceramic end effector.

The semiconductor ceramic end effector,ceramic handling arm, ceramic handling manipulator arm has excellent mechanical properties at room temperature, such as high strength, high hardness, high elastic modulus, excellent high temperature stability, such as high thermal conductivity, low thermal expansion coefficient, and good specific stiffness and optical processing performance, especially suitable for the preparation of photolithography machine and other integrated circuit equipment for precision ceramic structural parts. For example, it is used in the precision moving workpiece table, skeleton, suction cup, water cooling plate and precision measurement mirror, grating and other ceramic structural parts

Compared with metal arms, the advantages of using ceramic end effector to mount semiconductor parts are:

1. Ceramic end effector is more acid-resistant and alkali-resistant than metal arm. Longer service life in semiconductor processing;

2, the ceramic end effector is not easy to react with other substances, will not leave small particles with pollution and charged charges on the contact items, will not produce metal ions, will not pollute semiconductor parts;

3, in the semiconductor heat treatment, the ceramic end effector is also less heated deformation, reducing the deformation of semiconductor parts during heat treatment.

Machining accuracy of end effector:

(1) Axis: roundness 0.002mm, concentricity 0.002mm, finish Ra0.1;

(2) Hole: minimum machining aperture 0.2mm, depth up to 6 mm (depending on the material);

(3) slot (slot) : The minimum can be processed 0.1mm narrow slot, as well as various shapes of the slot;

(4) Plane: the minimum machined thin sheet thickness of 0.1MM, parallelism of 0.001mm, measurement tolerance of 0.001mm, finish Ra0.1;

Thread: The minimum can be machined M2 internal thread, accuracy GB-7h, external thread size is not limited.

Process range | |||||

Inside Diameter | ≥0.2mm | Length | ≤750mm | Internal thread | ≥2mm |

Outside Diameter | ≤400mm | Thickness | ≤400mm | External thread | ≤400mm |

Machining accuracy | |||||

roundness | 0.002mm | Parallelism | 0.003mm | Verticality | 0.005mm |

concentricity | 0.002mm | Flatnes | 0.002mm | Straightness | 0.005mm |

clearance fit | 0.003mm | tolerance of dimension | 0.001mm | surface roughness | Ra0.1 |

Custom Vacuum Suction Alumina End Effectors for Semiconductor Wafer Ceramic Handling Arm

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.