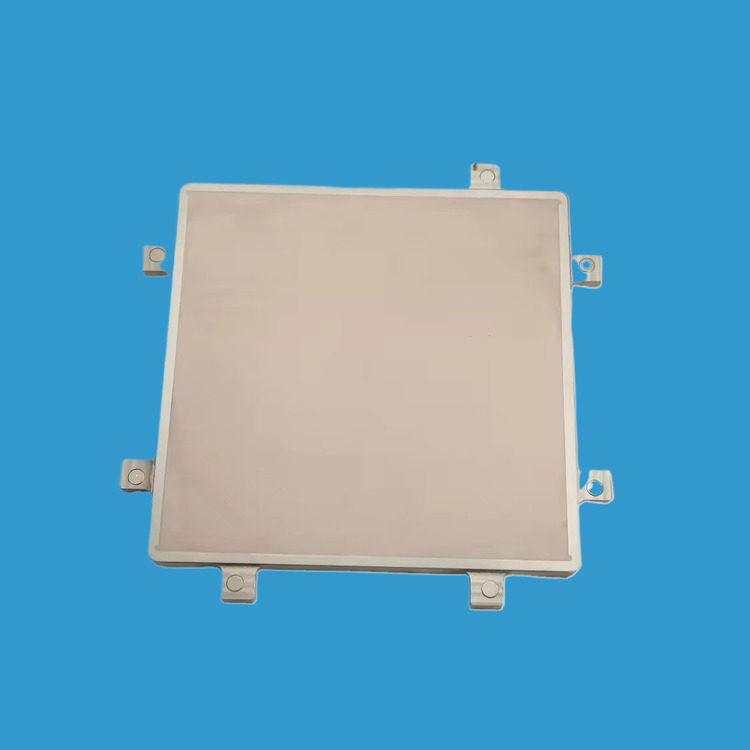

Custom semiconductor ceramic plate vacuum chucks semiconductor vacuum 99% alumina ceramic plate

Regular size:6, 8, 12 inches

Diameter Regular Tolerance:+/-0.10 mm

Regular Flatness:+/-0.10 mm

Regular Surface Roughness:Ra 0.8-1.6

4", 6", 8,” 12″are regular sizes, And pore size include 15um, 30um, 50um, 100um

Materials are alumina (Color: white, light brown, dark brown, blue-gray)

Custom size (like square, oval shape, or irregular shapes) is available for us

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Ceramic vacuum chucks with two features:

1, absorb the workpiece and paint it on the vacuum sucker.

2, the workpiece is floated and applied to the air float platform and non-contact transfer system.

Application principle:

When the air flow is set to enter the ceramic (vacuum pressure is negative pressure), the workpiece can be adsorbed.

When the airflow is set to flow out of the ceramic (vacuum pressure is positive), the part may puff up or not come into contact with the ceramic.Ceramic vacuum chucks application:

For the photoelectric industry, it can be used as:

1. Pick up and put the chuck

2. Combination stage

3. Air exposure

4. Non-contact transfer stage

For the semiconductor industry it can be used as:

1, the wafer heating

2. Wafer transfer

3, wafer cutting

4. Dicing machine

5, laser cutting

6, wafer grinding

7, wafer cleaning

6 ", 8 ", 12 "regular sizes, available in round, square, oval or irregular shapes and sizes.

Ceramic vacuum chucks have many pores through ceramic sintering technology and are used in semiconductor vacuum chucks. It can be used as an air float platform for a wide range of applications in semiconductors, panels, laser processes and non-contact linear sliding.

The application principle of Ceramic vacuum chucks:

By applying positive and negative pressure gas to absorb or float workpieces, including wafers, glass, PET films or other thin objects, the air flow of negative vacuum pressure is set to enter the ceramic, the workpiece can be adsorbed, the air flow of positive semiconductor vacuum pressure is set to flow out of the ceramic, the part can blow up or not touch the ceramic.

Regular size:6, 8, 12 inches

Diameter Regular Tolerance:+/-0.10 mm

Regular Flatness:+/-0.10 mm

Regular Surface Roughness:Ra 0.8-1.6

4", 6", 8,” 12″are regular sizes, And pore size include 15um, 30um, 50um, 100um

Materials are alumina (Color: white, light brown, dark brown, blue-gray)

Custom size (like square, oval shape, or irregular shapes) is available for us

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.