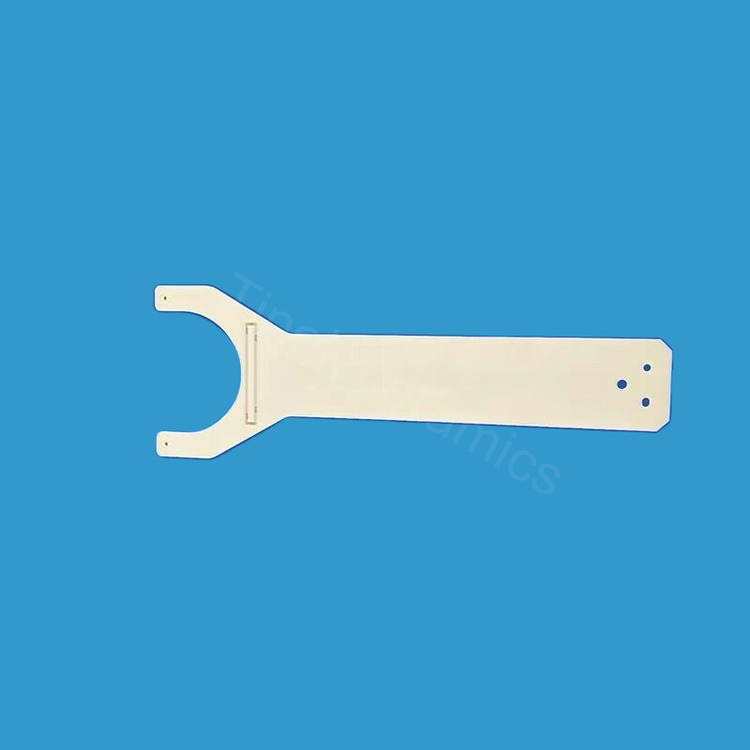

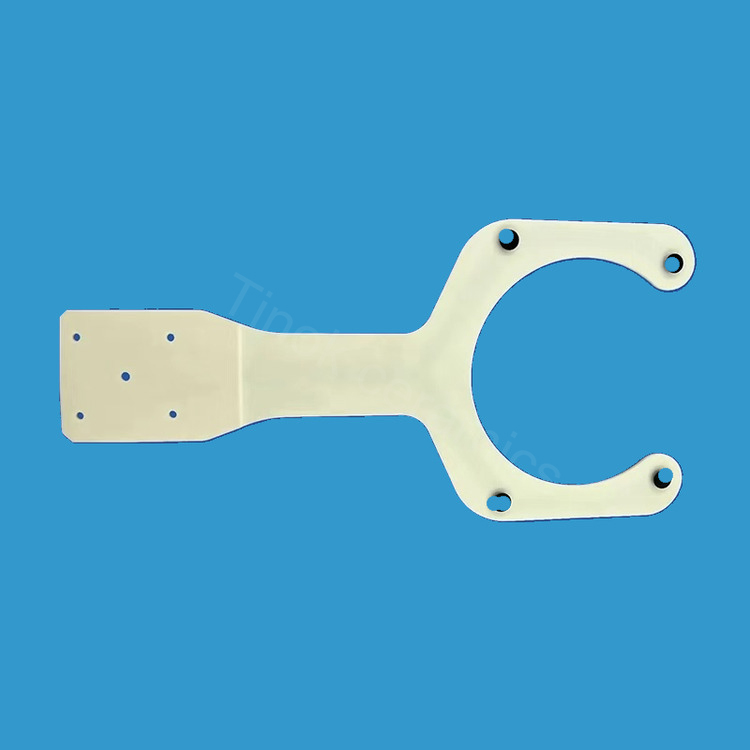

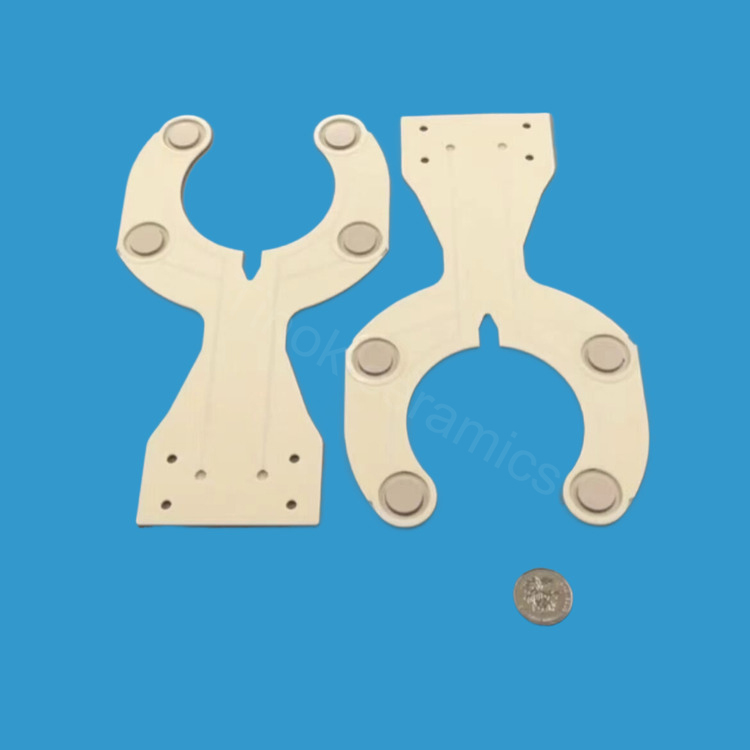

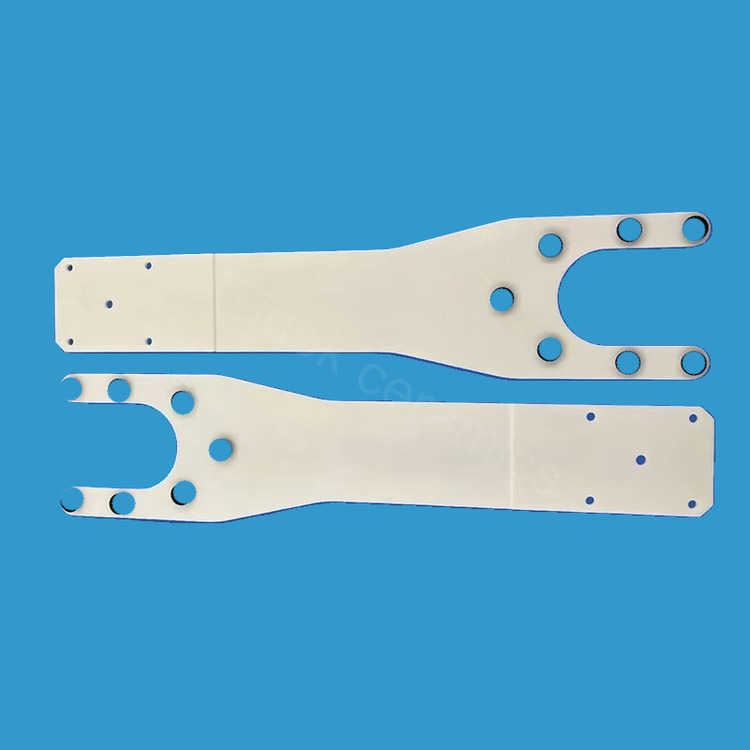

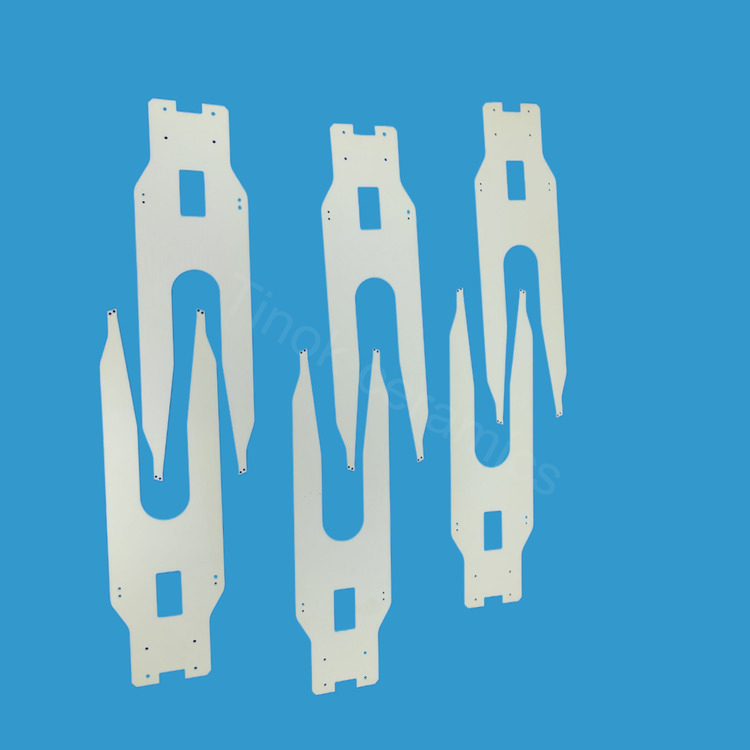

Semiconductor ceramic ceramic wafer handling al2o3 alumina ceramic semiconductor wafer arm end effector

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Material:Alumina ceramic 99%, 99.5%, 99.6%, 99.7%, 99.8%

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Semiconductor ceramic wafer handling is one of the important parts of semiconductor equipment, usually composed of controller, driver, arm and end actuator and other parts, with high cleanliness, high stability, high precision, high efficiency and high reliability. It is mainly used in the first step of semiconductor manufacturing, for moving, transporting and positioning semiconductor wafers.

Key Properties

• Hard, wear-resistant

• Excellent dielectric properties

• Good thermal conductivity

• Excellent size and shape capability

• High strength and stiffness

The ceramic wafer handling of the semiconductor equipment adopts the negative pressure suction method to take the chip, that is, the semiconductor wafer is adsorbed on the quartz or ceramic finger by the principle of the suction cup, and the semiconductor wafer is carried by the telescopic, rotating and lifting actions of the mechanical arm.

Since most processes are carried out in vacuum, high temperature and corrosive gas environment, the ceramic wafer handling arm used in the equipment should have excellent physical properties, such as: high mechanical strength, corrosion resistance, high temperature resistance, wear resistance, high hardness, insulation, etc., and advanced ceramic materials can just meet these conditions.

There are three main kinds of ceramic wafer handling arm, one is alumina ceramic wafer handling, and the other two are black ceramic and composite ceramic wafer handling. Among them, black alumina helps to absorb heat or provide better shading, which is particularly important for certain light-sensitive operations in the semiconductor industry. In short, these ceramic materials have the physical properties of high density, high hardness and high wear resistance, as well as good heat resistance, excellent mechanical strength, high temperature environment still has good insulation, good corrosion resistance and other physical properties, is an excellent material for the production of semiconductor equipment mechanical arm.

Ceramic wafer handling end effector ceramic wafer handling semiconductor wafer device

The ceramic wafer handling arm is made of high purity ceramic raw materials by cold isostatic pressing, high temperature sintering and precision machining. The dimensional accuracy can reach ±0.001mm, the finish can reach Ra0.1, and the use temperature can reach 1600℃. It uses a unique ceramic bonding technology, and the temperature of the hollow ceramic arm after bonding can reach up to 800℃.

Ceramic wafer handling arm application:

Semiconductor manufacturing: Ceramic wafer handling arms play an important role in the semiconductor manufacturing process and are often used to handle high-value materials such as silicon wafers to ensure the accuracy and stability of the process.

Machining industry: In processes requiring high precision machining, ceramic arms can be used as tools to ensure product accuracy and surface quality.

Medical devices: Ceramic arms are widely used in surgical robots and other medical devices, and their high accuracy and biocompatibility make them an ideal choice.

Chemical industry: Due to its excellent corrosion resistance, ceramic arms are also widely used in the chemical industry, especially in the environment with corrosive media.

Ceramic mechanical wafer handling arm features:

Wear resistance: Ceramic wafer handling arms have excellent wear resistance and can maintain a stable surface state for a long time.

Corrosion resistance: Ceramic handling arms can work in corrosive media and maintain stable performance.

High temperature resistance: The ceramic arm can work in a high temperature environment and is not easy to deform or melt, ensuring the stability of the process.

High precision: The ceramic handling arm has excellent dimensional stability and precision, enabling high precision operation.

Lightweight: Compared to metal arms, ceramic arms usually have a lower weight, reducing the load on the mechanical device.

Material | Alumina ceramic |

Size | According to drawings or samples |

Torlerance | +/- 0.01mm |

Lead time | 10-30 days |

Delivery | Air Express (DHL/UPS/TNT/ FedEx) |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.