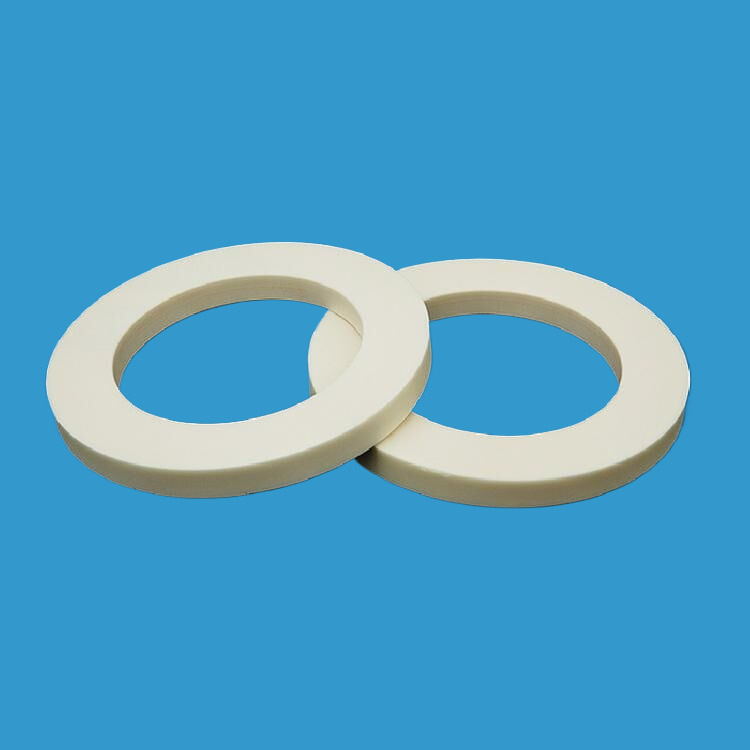

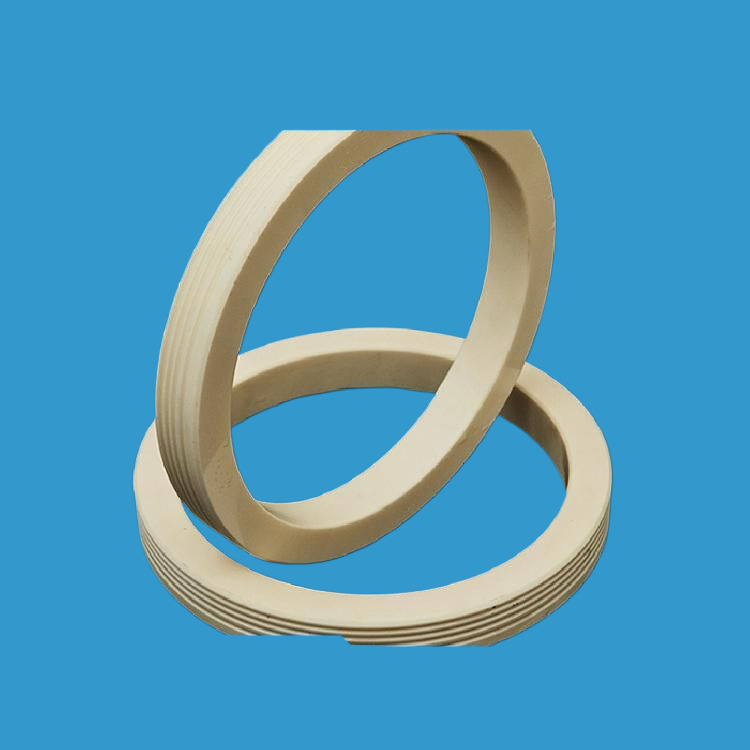

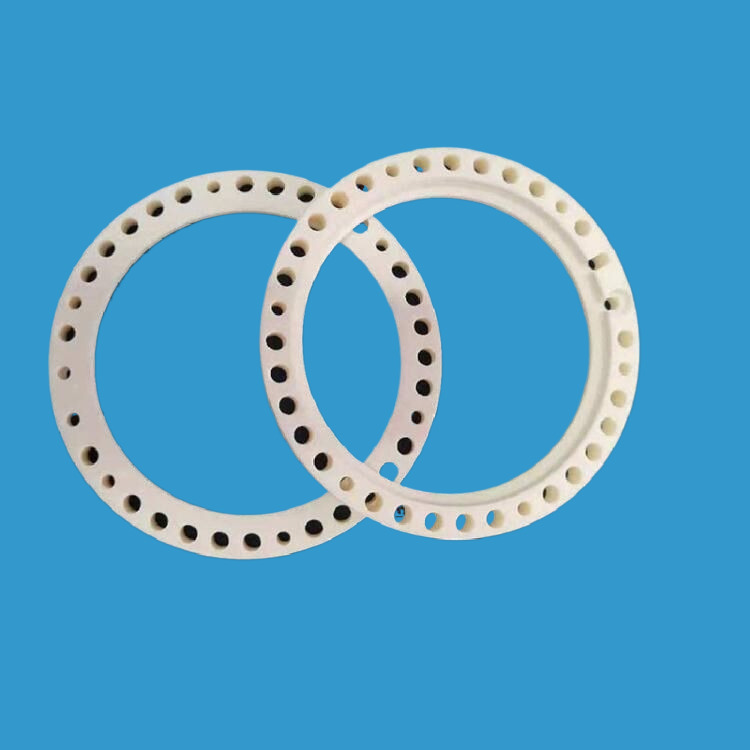

Semiconductor ceramic ring high purity al2o3 alumina ceramic seal rings in semiconductor equipment

Feature:High Hardness, High Strength,High Wear Resistance

Size:Conventional size Diameter 10 mm-350 mm Customizable

Application:Vacuum,Machinery, Electronic, Chemical,semiconductor equipment, NewEnergy

Surface Finish:Customizable

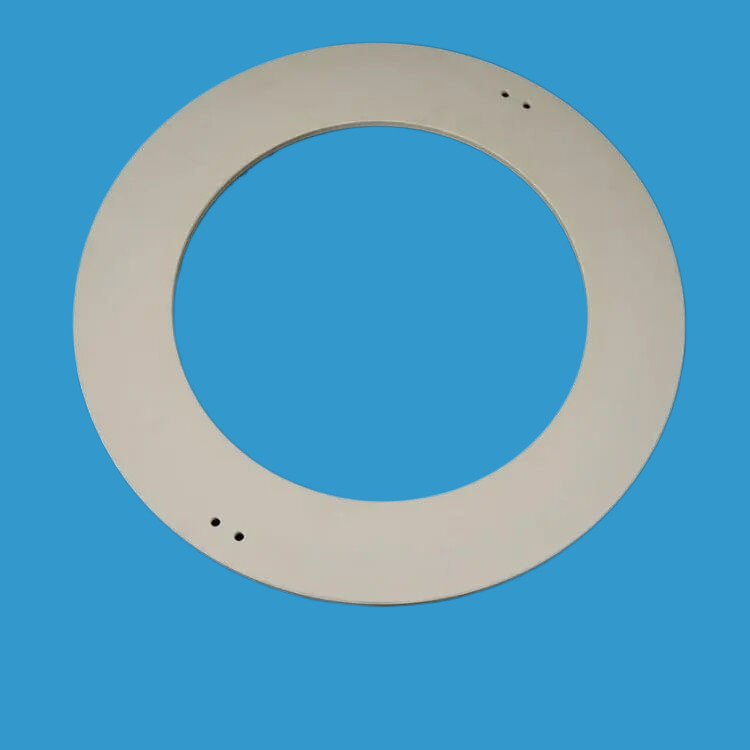

Size:8 inch

Inside diameter:250+0.5mm

Outer diamete:296+0.5mm

Thickness :1.2+0.1mm

Shape:Customized,Ring

Payment Term: PayPal; T/T; L/C etc.

Shipment: by sea by air by courier by post etc.

Because of its position and importance in semiconductor equipment, advanced ceramic ring parts must meet the comprehensive performance requirements of semiconductor equipment for materials in mechanical mechanics, heat, dielectric, acid and alkali resistance and plasma corrosion, and high precision requirements, because ceramic rings in semiconductor equipment are usually closely around the wafer, and some even directly contact the wafer. Therefore, the control of metal ions and particles on its surface is extremely strict. In addition, because the production of ceramic rings for semiconductor devices involves original equipment manufacturer certification, it is a high-threshold industry for exclusivity.

Features of alumina ceramic ring in semiconductor equipment

Purity:92%,95%,96%,99%,99.5%,99.7%,99.8%.

1. Good mechanical strength

2. Excellent electrical insulation

3. High-frequency loss

4. Good thermal conductivity

5. Heat,wear and corrosion resistance

Compressive Strength:2000Mpa/ 2091Mpa/ 2512Mpa/ 3500Mpa

Tensile Strength @ 25°C:140Mpa/150Mpa/200Mpa

Flexural Strength @ 25°C:331Mpa /276Mpa /324Mpa /500Mpa

Elastic Modulus:290GPa /331GPa /366GPa /380GPa

Maximum Working Temp:1650℃/1700℃

Thermal Conductivity @ 25°C :25 ,28.1, 30.7 ,33 (W/mK)

Item | Data |

Size | 8 inch |

Inside diameter | 250±0.5mm |

Outer diameter | 296±0.5mm |

Thickness | 1.2mm-1.5mm |

Color | Silver |

Packaging | PE bags , blister bags , Export cartons |

OEM/ODM | Available |

Precision machining ceramic video

Machining parameters of ceramic parts

The following are some of our ceramic parts processing parameters. For specific precision ceramic parts processing parameters and processing flow, please contact us.

- Dimensional accuracy: up to 0.001mm

- Surface finish: Up to Ra0 · 03

- Concentricity: up to 0.003mm

- Parallelism: up to 0.002mm

- Inner hole tolerance: minimum machined 0.005mm

- Straight groove: The narrowest machined groove is 0.1x100mm

- Cylindricity: up to 0.004mm

- Linear tolerance: up to 0.001mm

Our Services - Need any help!

Find the latest ceramic parts quotes, accurate ceramic parts parameters, comprehensive ceramic parameter performance? Please contact us.

Our ceramic parts engineers communicate directly with customers, quickly understand the parameters, customer requirements details, efficient and fast to give solutions and reply information, provide quick consulting quotes.

- Support sample manufacturing and testing

- Support drawing

- Multiple ways of communication

- Support customization

- Engineer direct communication

- On-time and fast shipment

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.