Al2O3 Alumina ceramic

What is alumina ceramic material?

Alumina ceramics are a kind of alumina (Al₂O) as the main body of the ceramic material, according to its alumina purity can be divided into high purity type and common type two, the use is also different.

High purity alumina ceramics refer to those in which the content of

Al₂O₃ is more than 99.9%. Due to the sintering temperature of 1700℃ and

transmission wavelength of 1 ~ 6μm, they are generally made into molten

glass to replace the platinum crucible. Use its light transmission and

alkali metal corrosion resistance as sodium lamp tube; It can be used as

integrated circuit board and high frequency insulation material in the

electronics industry.

The common alumina ceramics are divided into 99 porcelain, 95 porcelain, 93 porcelain, 92 porcelain, 85 porcelain and other varieties according to the content of Al₂O₃, which is mainly used in the field of industrial anti-wear. Among them, 99 alumina porcelain materials are used to make high temperature crucible, refractory furnace pipe and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valves; 95 alumina porcelain is mainly used as corrosion resistance and wear resistance parts; The 85 porcelain is often mixed with talc to improve the electrical properties and mechanical strength, and can be sealed with molybdenum, niobium, tantalum and other metals, and some are used as electric vacuum devices.

Alumina ceramics are sintered by high-quality alumina powder, at 1700℃

high temperature, alumina will be converted into α alumina, forming a

special crystal structure, not only hardness exceeds RHA85, second only

to diamond, excellent wear resistance, far more than wear-resistant

steel, cast stone cast iron and so on. And the chemical properties of

αalumina are stable, can resist most acid and alkali corrosion, and its

high temperature resistance is also very strong, aluminum oxide ceramic

liner and aluminum oxide ceramic pipe are widely used in the field of

industrial anti-wear.

Physical parameter table of alumina Ceramics

The following table lists the common physical parameters of alumina ceramics:

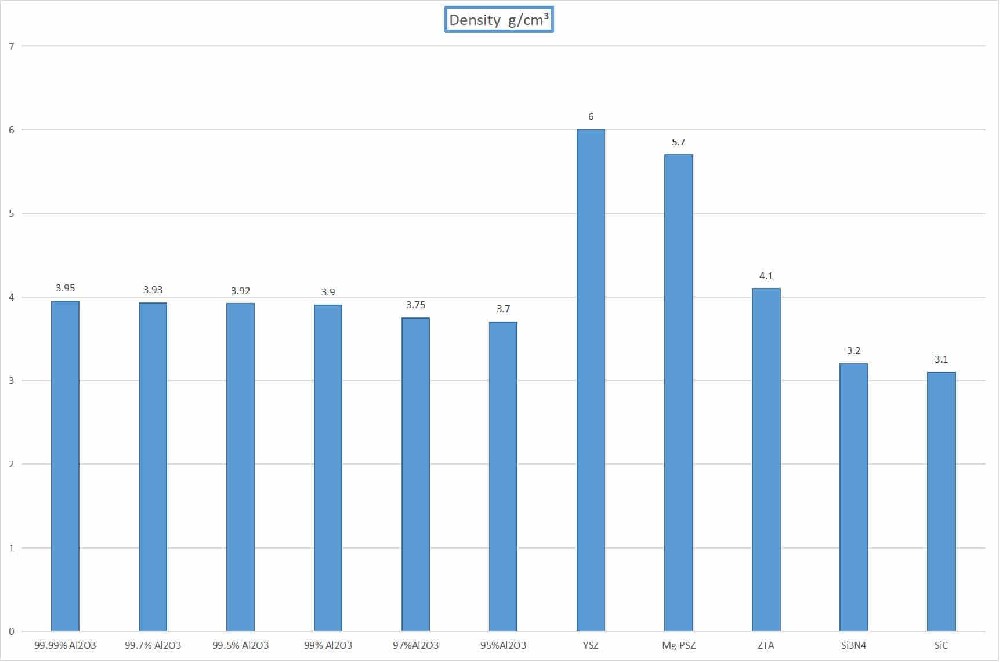

| Physical parameters | Numerical range |

| Density | 3.85 ~ 3.95 g/cm³ |

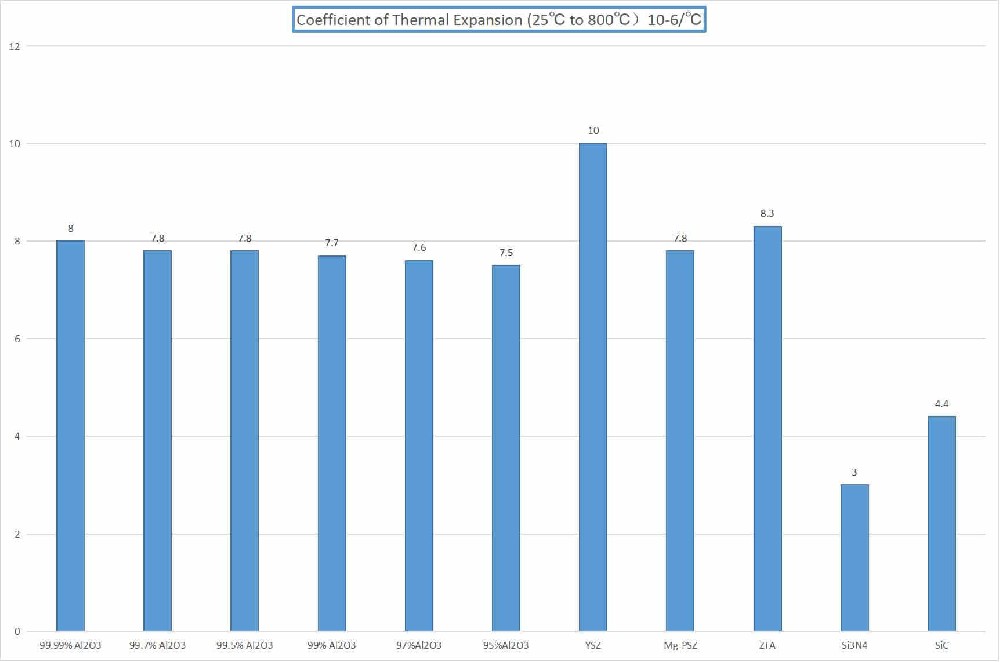

| Coefficient of thermal expansion | 7.0 ~ 8.3 × 10^-6/℃ |

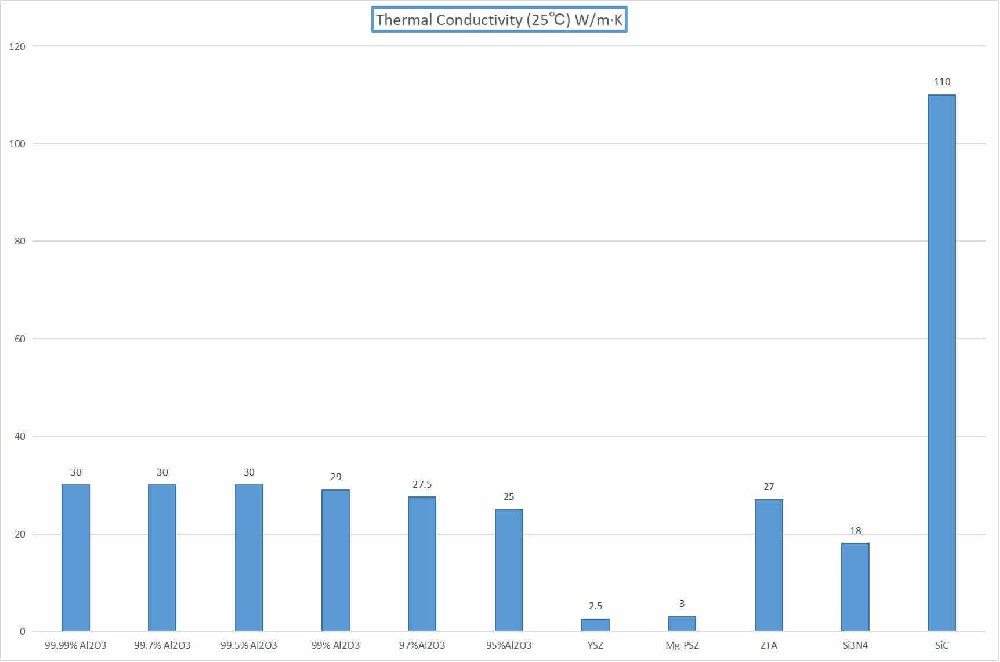

| Thermal conductivity | 25 ~ 30 W/(m·K) |

| Heat capacity | 0.75 ~ 1.3 J/(g·K) |

Alumina ceramics composition and classification

Alumina ceramics are classified into different types based on the content of alumina (Al₂O₃) :

0.75 porcelain (about 75% Al₂O₃).

0.85 porcelain (about 85% Al₂O₃).

0.95 porcelain (Al₂O₃ content ≥95%).

0.99 porcelain (Al₂O₃ content ≥99%).

Ultra-high purity type (Al₂O₃ content >99.9%)

Characteristics and advantages of alumina ceramics

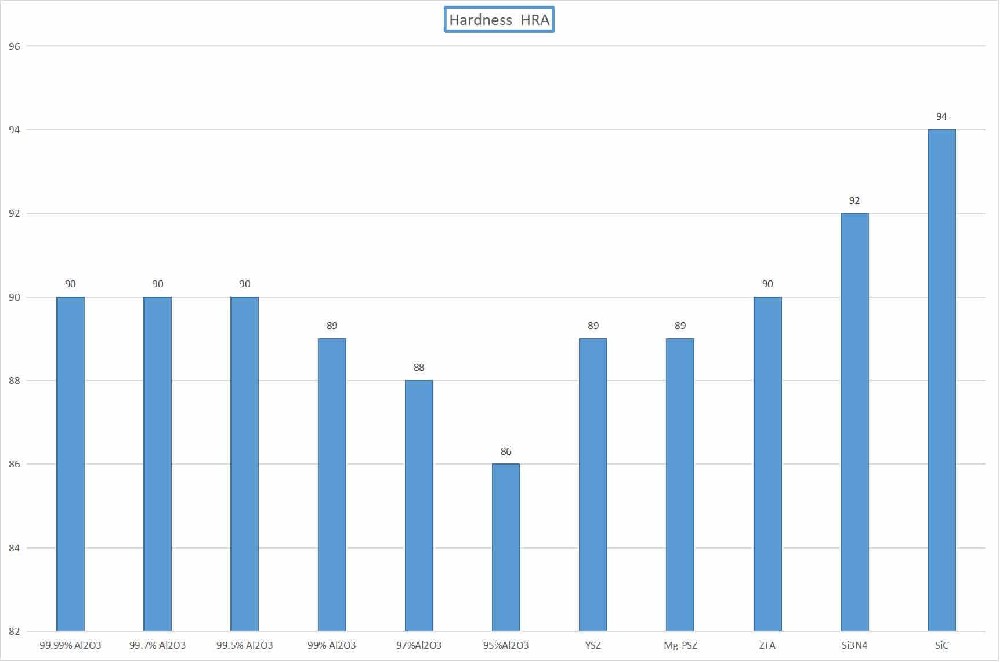

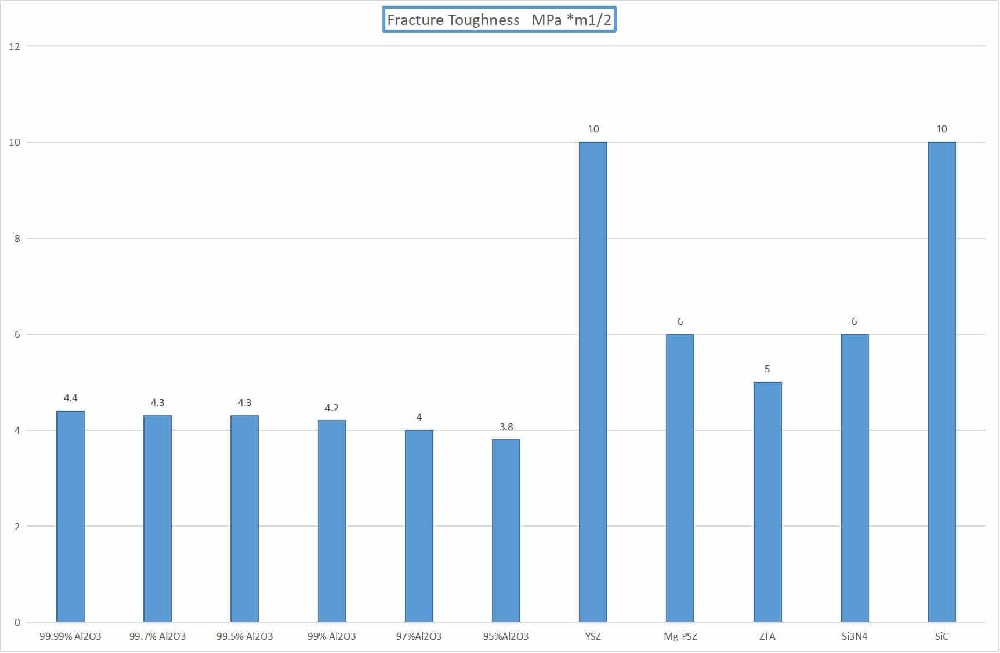

High hardness and wear resistance

According to the determination of the Shanghai Institute of Ceramics, Chinese Academy of Sciences, the Rockwell hardness of alumina ceramics reaches HRA80-90, second only to diamond in hardness.

Light in weight and a master at reducing load

Its density is only 3.5g/cm³, approximately half that of steel. In some equipment or structures with strict weight requirements, the use of alumina ceramic structural components can significantly reduce the load.

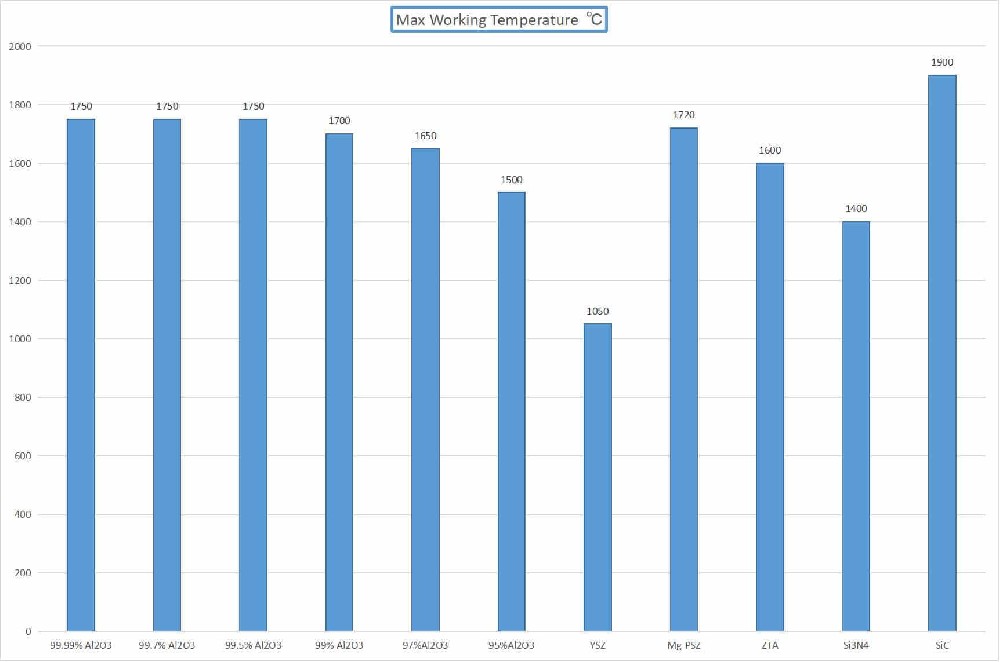

High temperature resistance

Alumina ceramics have excellent heat resistance, and the continuous service temperature can reach over 1000℃. In high-temperature industrial furnaces, metallurgy and other high-temperature environments, it can maintain a stable structure and performance without softening or deforming.

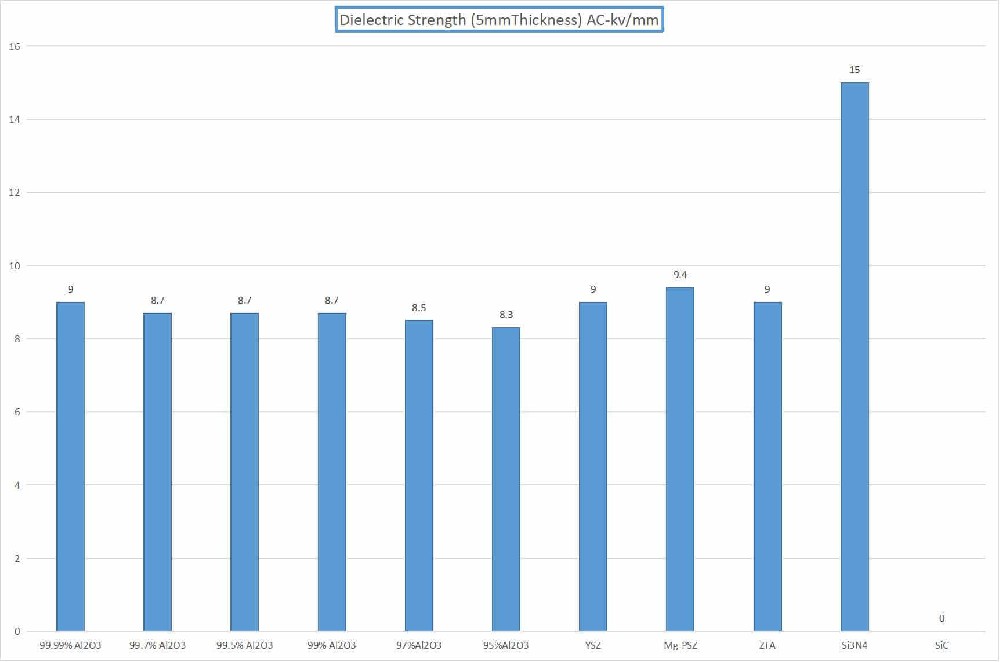

Excellent electrical insulation, current "insulator"

It has a high resistivity and outstanding electrical insulation performance. The resistivity at room temperature can reach 10¹⁵ω · cm, and the insulation strength is above 15kv/mm.

It has good chemical stability and is not afraid of acids and alkalis

common strong acids such as sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid do not react with Al₂O₃, and many complex sulfides, phosphides, chlorides, etc. are also difficult to affect it. In fields such as chemical engineering and environmental protection, when in contact with various corrosive media, alumina ceramic structural components can work stably for a long time, demonstrating strong corrosion resistance.