DONGGUAN TINOK PRECISION CERAMICS CO., LTD

TINOK Precision Ceramics is a professional factory of producing precision ceramic (Zirconia, Alumina, Si3N4, SiC) products that serving both domestic and overseas customers.The TINOK company offers one to stop service, from forming, sintering, processing and inspection, mainly accepting customization based on drawings and samples...

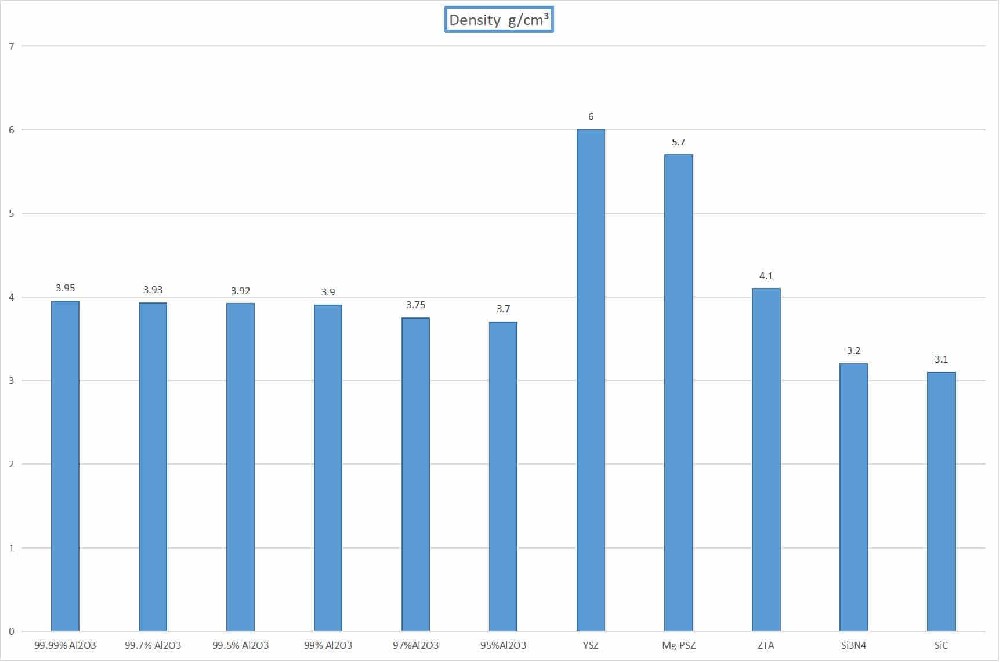

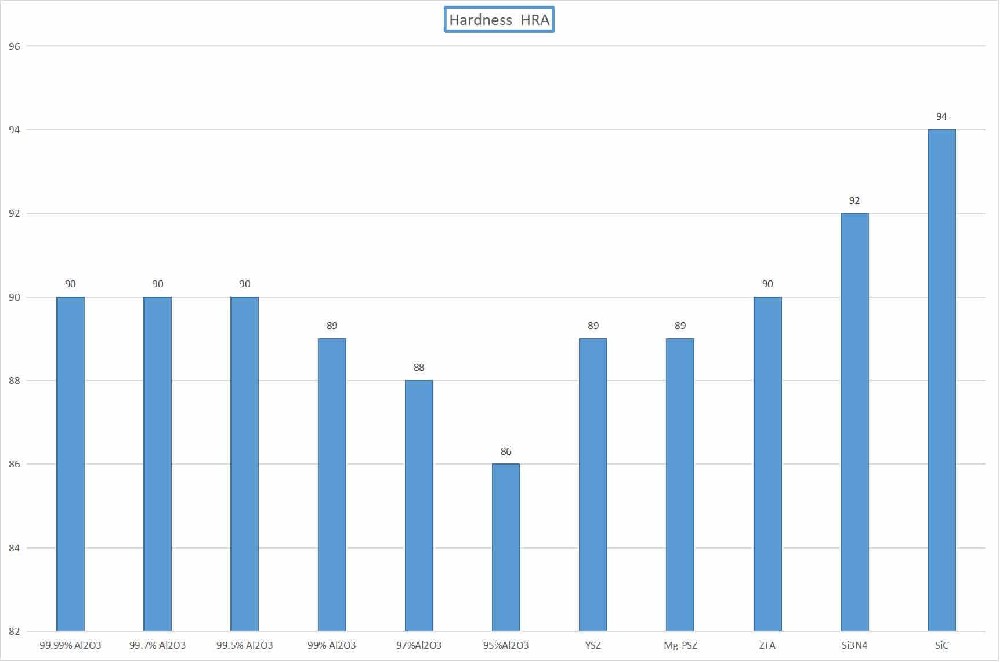

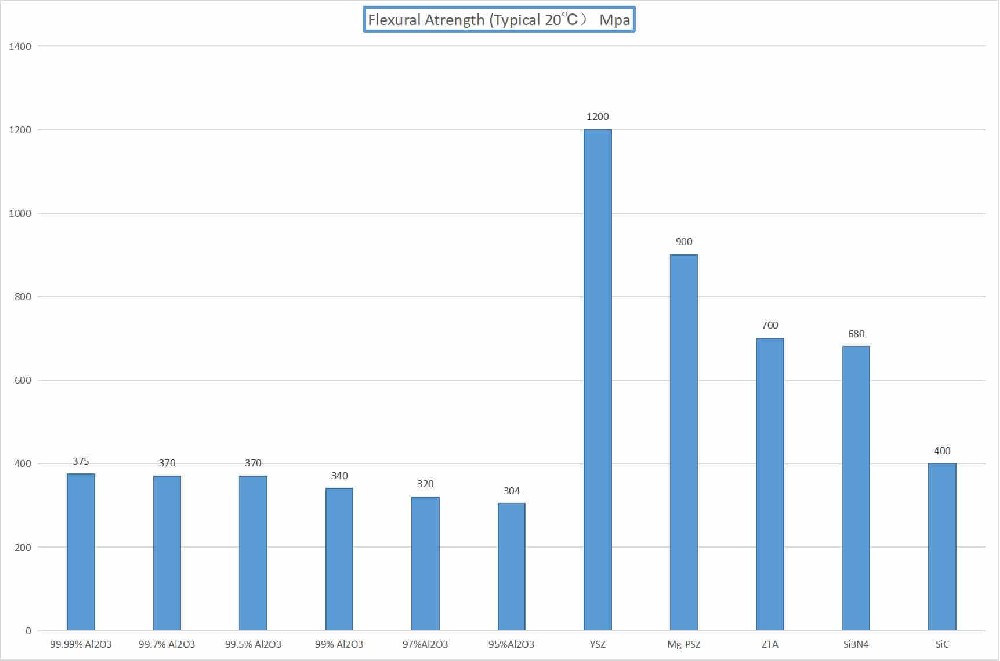

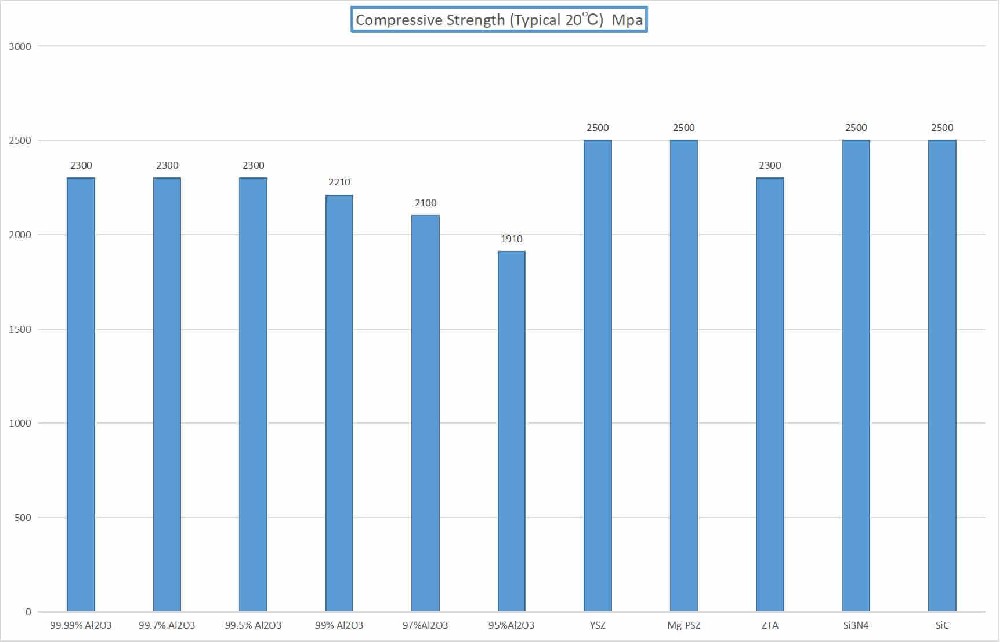

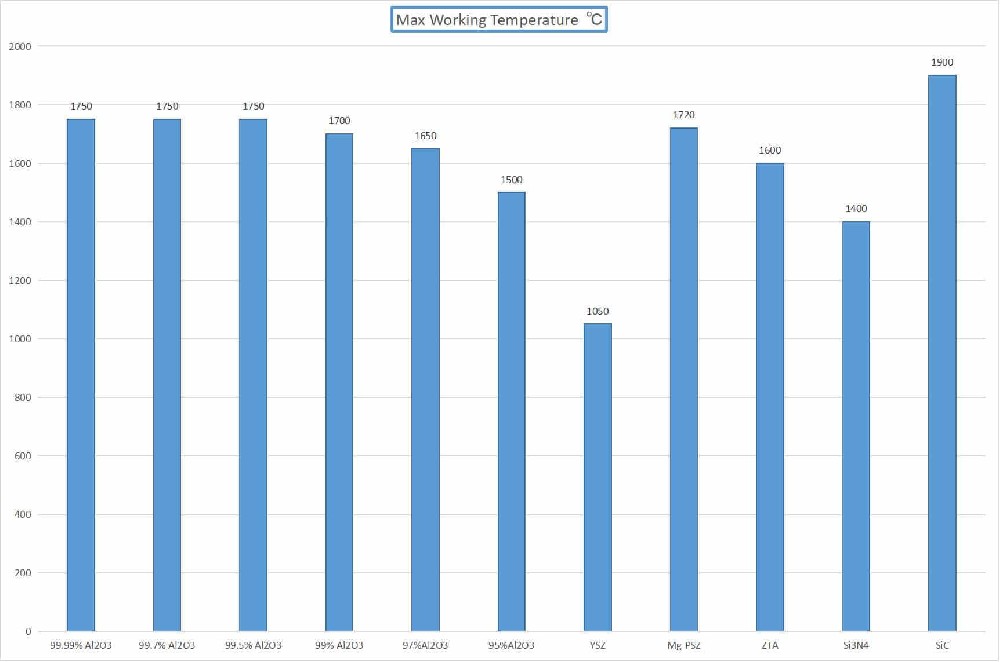

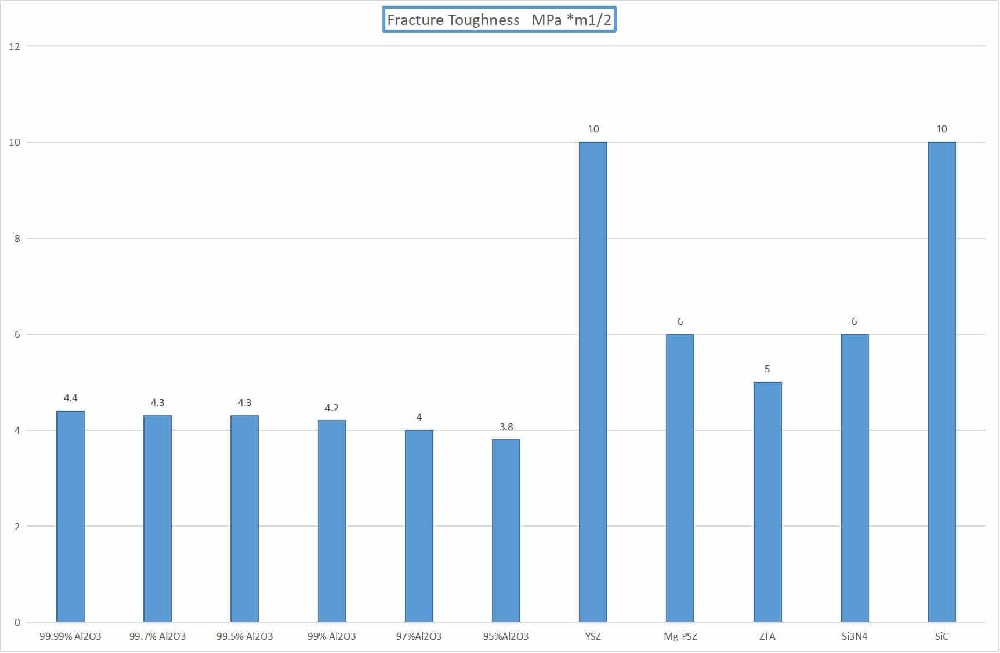

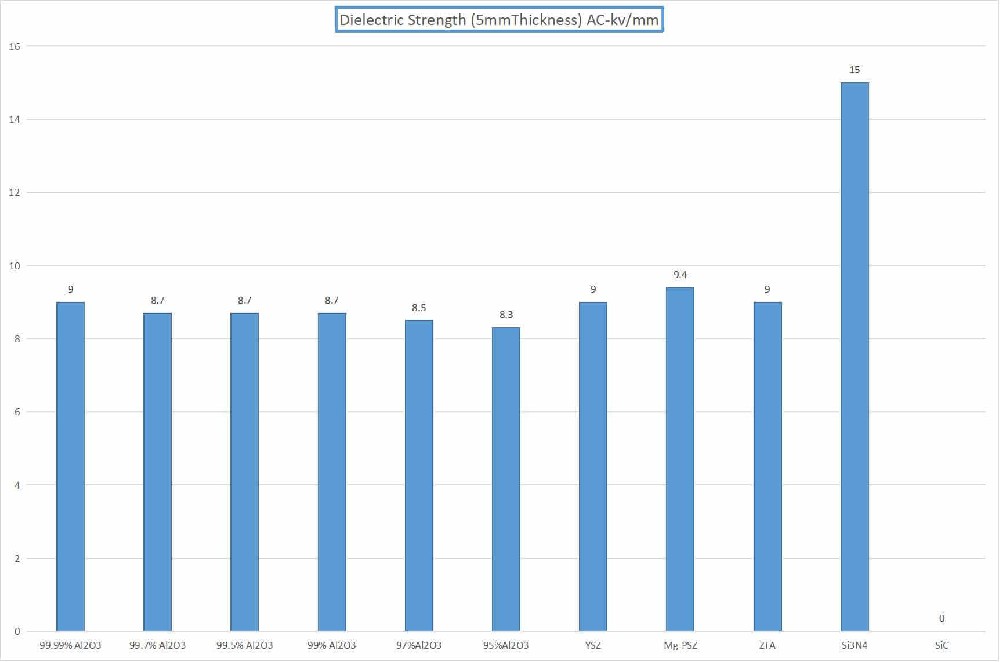

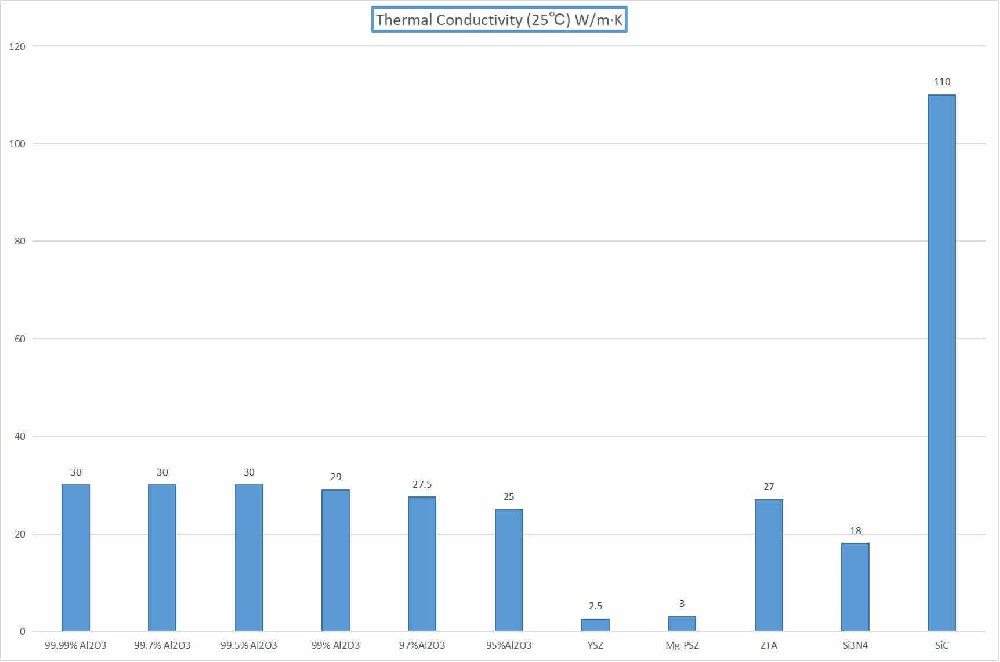

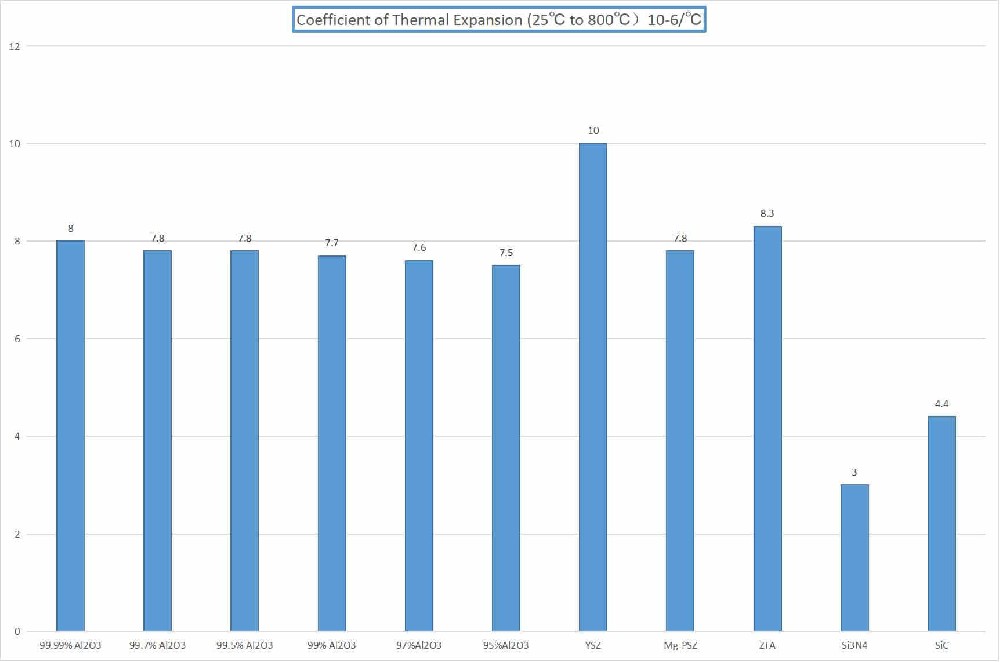

Our main raw materials for ceramics parts

Our some ceramics parts

| ceramic rod | ceramic tube | ceramic flange |

| ceramic ring | ceramic bushing | ceramic sleeve |

| ceramic pump | ceramic parts | ceramic plunger shaft |

Ceramic plunger rod high precision polishing ceramic piston tubes

More details

Water jet ceramic plunger high polished wearable waterjet parts ceramic plunger rod

More details

General pump ceramic plunger pump ceramic part plunger piston rod tubes

More details

Ceramic plunger rod high precision polishing Al2O3 and ZrO2 ceramic plunger rods

More details

Ceramic piston rod Al2O3 alumina ZrO2 zirconia ceramic piston rod

More details

Alumina ceramic plunger low thermal expansion Al2O3 Aluminium oxide ceramic plunger

More details

Zirconia ceramic plunger high hardness corrosion resistance ZrO2ceramic plunger

More details

Metalization ceramic tube high mechanical strength and bonding strength ceramic tubes

More details

Customized alumina ceramic tube high purity al2o3 machinable aluminum oxide ceramic tubes

More detailsWe can provide different types, different shapes, different size parameters, different ceramic materials, different processing methods of ceramic parts

More type ceramic parts Contact usCeramic parts video

Application of advanced ceramics

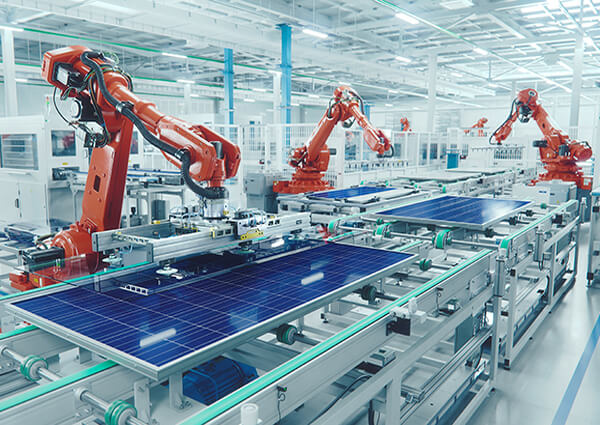

Advanced Ceramics, as a material type, has a wide range of applications in various fields due to its unique physical, chemical and mechanical properties. Ceramic parts are widely used in semiconductor industry, photovoltaic industry, new energy vehicles, mining, oil fields, electronics, machinery and so on

Motor transport

Alumina ceramics and aluminum nitride ceramics are used in transportation mainly because of their light weight, high temperature resistance, heat insulation, electrical insulation, wear resistance, corrosion resistance, safety and reliability.

Energy supply

In power plant engines and turbines or photovoltaic systems, solar thermal energy conversion, wind energy and hydroelectric power systems, alumina ceramics, silicon nitride ceramics, aluminum nitride ceramics can withstand extreme temperatures and mechanical stresses.

Equipment and engineering

Excellent wear resistance, high temperature resistance, chemical resistance and high corrosion resistance make alumina ceramics and silicon nitride ceramics a safe alternative to other materials in equipment, machinery and plant engineering.

Medical equipment

Zirconia ceramics and alumina ceramics are special materials for use in medical devices because of their wear resistance, long service life, and biocompatibility.

DONGGUAN TINOK PRECISION CERAMICS CO., LTD

About tinok precision ceramics

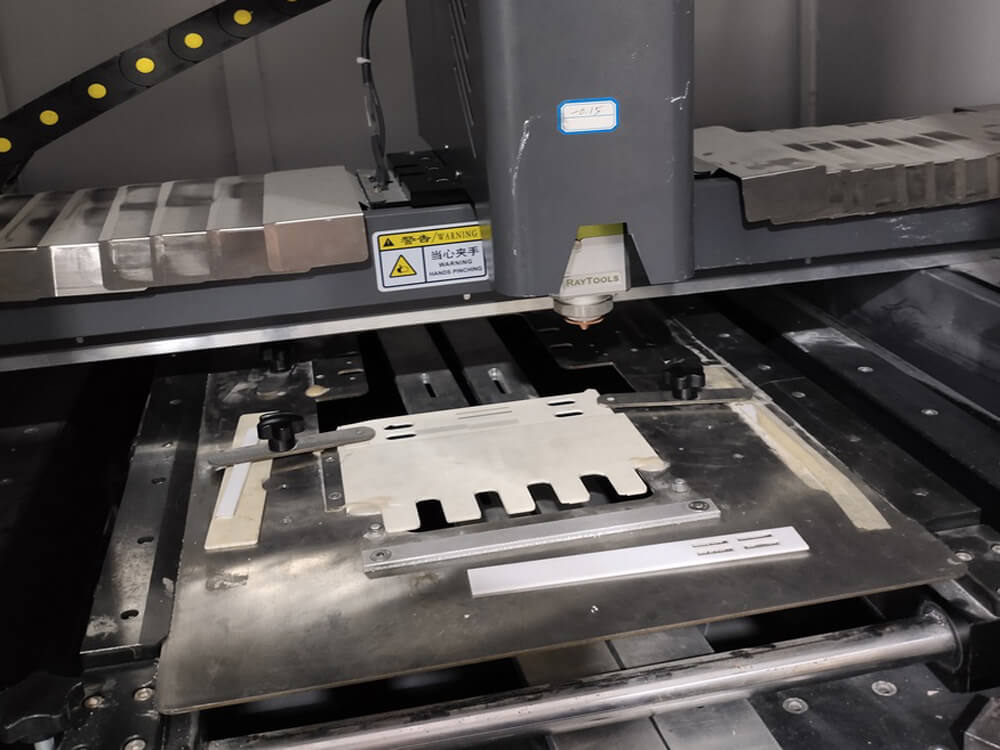

TINOK Precision Ceramics was established in 2016, located in Dongguan city, China. It’s a professional factory of producing precision ceramic (Zirconia, Alumina, Si3N4, SiC) products that serving both domestic and overseas customers. The company offers one to stop service, from forming, sintering, processing and inspection, mainly accepting customization based on drawings and samples. The precision ceramic products we produce are widely used in industries such as photovoltaic & new energy, semiconductors, medical & food, measuring tools, electronic appliances, petroleum & mining, military, aerospace, etc., to meet the diverse needs of customers. TINOK Ceramics has a complete set of production equipment, such as molding equipment: isostatic pressing molding machine, dry pressing molding machine, injection molding machine; Sintering furnace; Processing equipment: flat grinding, centerless grinding, internal cylindrical grinding, external cylindrical grinding, internal & external cylindrical grinding, honing, punching, CNC machining center, etc. In addition, the company obtained ISO 9001-2015 quality system certification and independent import-export license.

Related Ceramic Blogs

Ceramic related information, such as performance, application, advantages, dynamics and other information.

Ceramic plate cnc machining process

Cnc machining of ceramic plate is a method of precision machining of ceramic ···

More...Zirconia ceramic performance test method

As a special industrial ceramic, zirconia ceramics are used in various fields···

More...What is the thermal conductivity of alumina ceramics?

Analysis of thermal conductivity of alumina ceramicThe therm···

More...What is ceramic parts machining?

Ceramic parts machining is a complex and precise process that requires h···

More...Need any help!

Find answers to frequently asked questions about Tionk ceramic parts, contacts and general customer business information

Contact UsWe Provide Consulting for every ceramic parts

We can provide customers with material properties of ceramic parts, ceramic parts design, parameter modification, manufacturing samples and ceramic parts performance testing

Leave a Messages