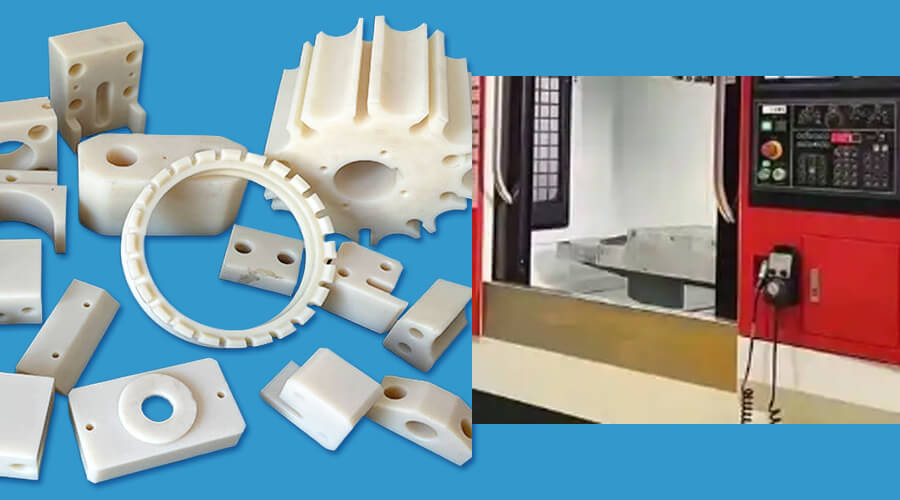

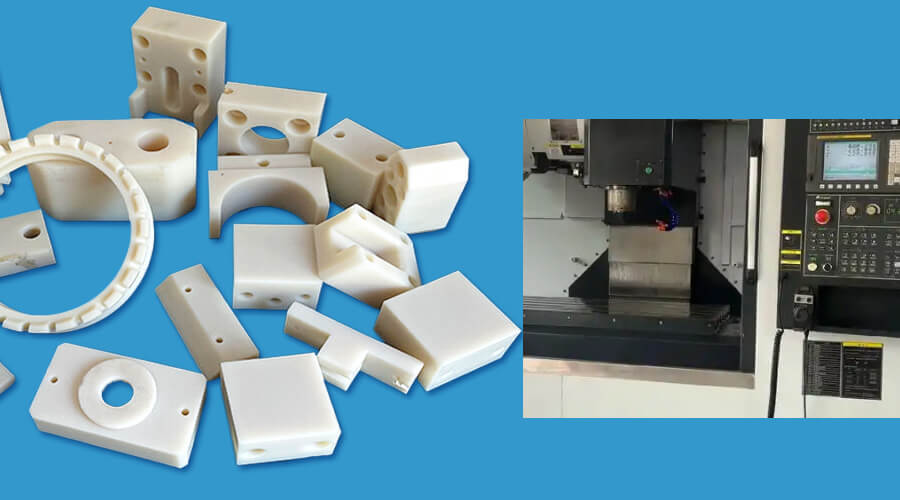

Ceramic plate cnc machining process

Cnc machining of ceramic plate is a method of precision machining of ceramic materials using computer digital control (CNC) machine tools, which is mainly used to produce parts or models with high precision, high hardness and wear resistance.

Because of its excellent mechanical properties and chemical stability, ceramic materials have been widely used in aerospace, medical equipment, electronics industry and high-performance cutting tools. However, due to the very high hardness of ceramics, its processing is relatively difficult. The following will be a detailed analysis of the main steps and technical points of cnc machining of ceramic plates.

Design and Programming:

First, a 3D model is created according to the design requirements of the product, and then a CNC machining program is written based on this model. This program will specifically guide the CNC machine to process according to the preset path and parameters, ensuring the accuracy of subsequent operations.

The physical properties of the ceramic, such as brittleness and hardness, should be considered in the design to optimize the processing path and reduce the risk of breakage during processing.

Equipment selection and preparation:

Choose a CNC machine tool suitable for ceramic processing, usually a high-precision, high-rigidity CNC machine tool, equipped with diamond or silicon nitride abrasive tools as cutting tools.

Before starting processing, it is necessary to properly debug and maintain the equipment to ensure that it is in the best working condition and avoid processing errors caused by equipment problems.

Material preparation and fixing:

Select the appropriate ceramic material according to the needs of the hand plate model, such as alumina, zirconia or silicon nitride. These materials should have good processing properties and adaptability to ensure the smooth processing process.

The material is fixed on the machine tool to ensure that the material will not shift or deform during the processing, ensuring the processing accuracy and quality.

Roughing and finishing:

Through roughing, the excess material is quickly removed and the required part shape is initially formed. This step focuses on processing efficiency and lays the foundation for subsequent finishing.

Using finishing technology, parts are finely ground and polished to ensure precise dimensions and ideal surface quality. This step requires special attention to processing details and quality control.

Post-processing and quality inspection:

After all processing steps are completed, the parts are cleaned to remove cutting fluid and debris from the surface. Then, the detailed quality inspection, including dimensional accuracy, appearance quality and functional testing, is carried out to ensure that the hand-plate model meets the design specification.

Surface treatment, such as coating or heat treatment, is performed as required to improve the corrosion resistance, wear resistance or service life of the part.

Technical advantages and challenges:

Ceramic CNC machining has the advantages of high precision, high hardness and long durability, and can manufacture extremely wear-resistant and high-temperature parts.

However, this technology also faces some challenges, such as difficult processing, rapid tool wear, and high cost. Therefore, it is necessary to continuously optimize the process and upgrade the skill level of the operators.

Industry application case:

In the field of medical devices, ceramic CNC machining can be used to manufacture high-precision parts such as artificial joints and dental implants, which require long-term stable performance and good biocompatibility.

In the electronics industry, ceramic CNC machining is used to produce high-performance electronic component bases and insulation parts that require high hardness and excellent thermal stability.

In summary, cnc machining of ceramic plates has been widely used in many high-end manufacturing fields because of its high precision and excellent material properties. Through strict control of each link, combined with advanced equipment and technology, efficient and high-quality parts processing can be achieved, thus promoting the progress and innovation of the industry.