Alumina Ceramics(AL2O3)

Alumina ceramics are a kind of alumina (AL2O3) as the main body of the ceramic material, according to its alumina purity can be divided into high purity type and common type two, the use is also different.

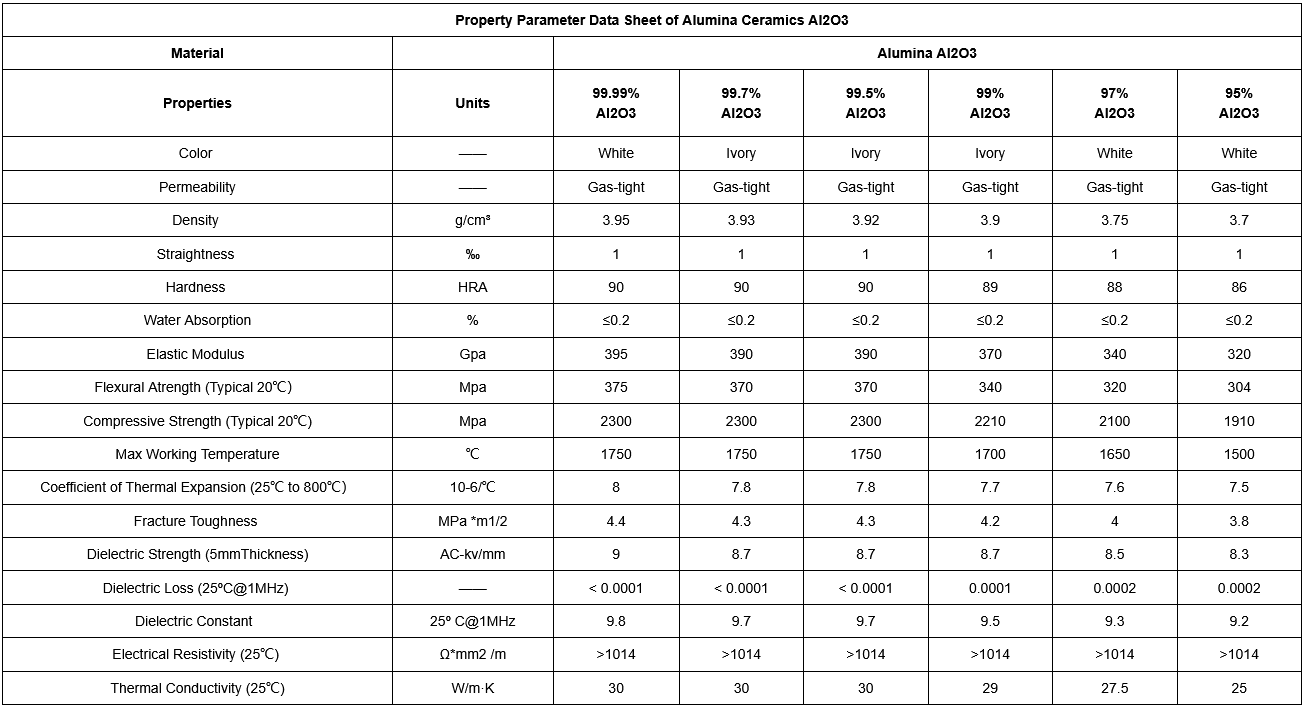

We can offer alumina ceramics products with different proportions(95%to99.99% Al2O3).99.99 Alumina ceramic/99.9 Alumina ceramic/99.7 Alumina ceramic/99.5 Alumina ceramic/99 Alumina ceramic/97 Alumina ceramic/95 Alumina ceramic

Alumina as a precision ceramic material has a number of excellent properties, including high hardness, excellent chemical stability, high temperature stability, good insulation properties and dimensional stability. This makes it an important application in a variety of fields such as wear-resistant parts, chemical utensils, high-temperature heating elements, electronic insulators and components with high precision dimensional control requirements.

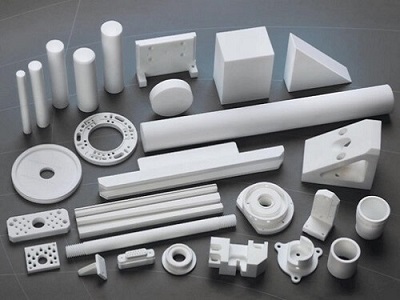

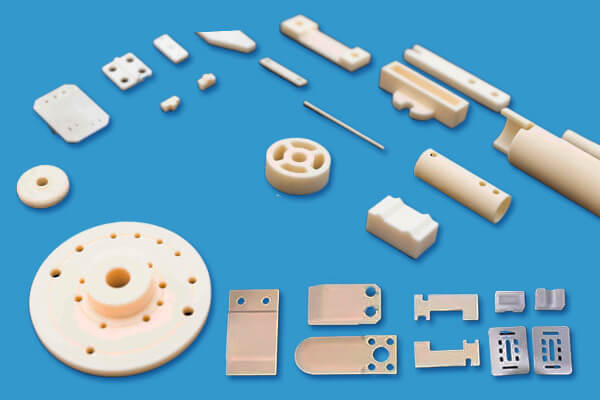

Related Alumina ceramic part products

Tinok Precision Ceramics offers high quality alumina ceramic accessories. A variety of alumina ceramic processing methods, including machining or net forming, can be applied to produce parts of various sizes and shapes. In addition, it can be easily attached to metals or other ceramics using metallization and brazing techniques...

Advantages

Alumina ceramics refers to alumina as the main raw material, through forming, sintering, grinding and other processes made with high strength and high hardness and other physical and chemical properties of industrial ceramic materials.

- Good strength and stiffness

- Good hardness and wear resistance

- Good corrosion resistance

- Good thermal stability

- Excellent dielectric properties (DC to GHz frequencies)

- Low dielectric constant

- Low loss Angle tangent

Applications

Alumina ceramics are the most widely used and widely used oxide ceramics. In the preparation process, we can adjust the raw materials and sintering conditions of alumina ceramics to achieve different performance characteristics, so that it has a wide range of applications in many fields.

- Industrial field: such as refractory materials, stoves, furnaces, grinding media, abrasives, etc.

- Electronic and electrical appliances: alumina ceramics have good insulation properties, and can be used for electronic components, electrical insulators, microwave components, etc.

- Chemical industry: alumina ceramics have excellent corrosion resistance and can be used for lining, pumps, valves, pipelines and so on.

- Environmental protection: Alumina ceramics can be used for environmental protection equipment, such as purifiers, filters, catalyst carriers, etc.

- Medical field: Alumina ceramics have good biocompatibility and can be used in medical implants, prostheses and so on.

- Other industries

Alumina Material Properties

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)