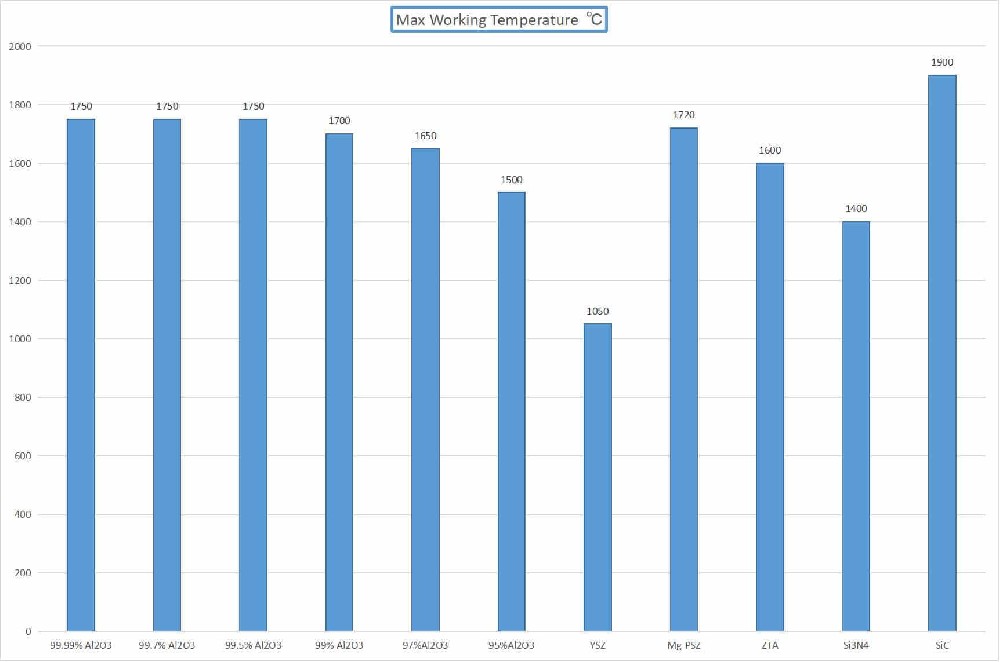

Ceramic Max Working Temperature

The thermal properties of ceramics can withstand how high the temperature.

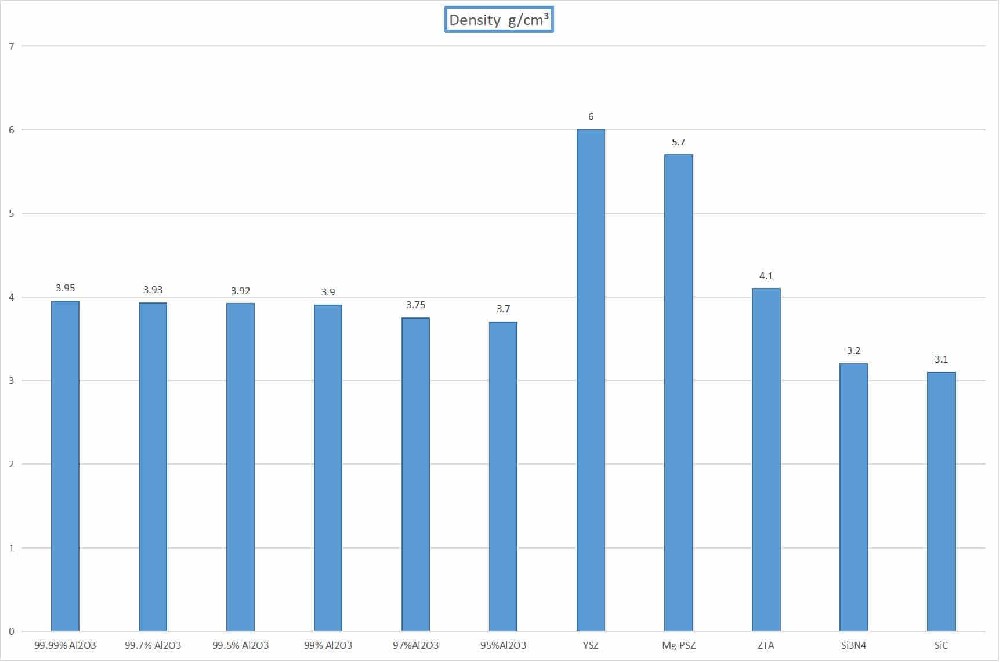

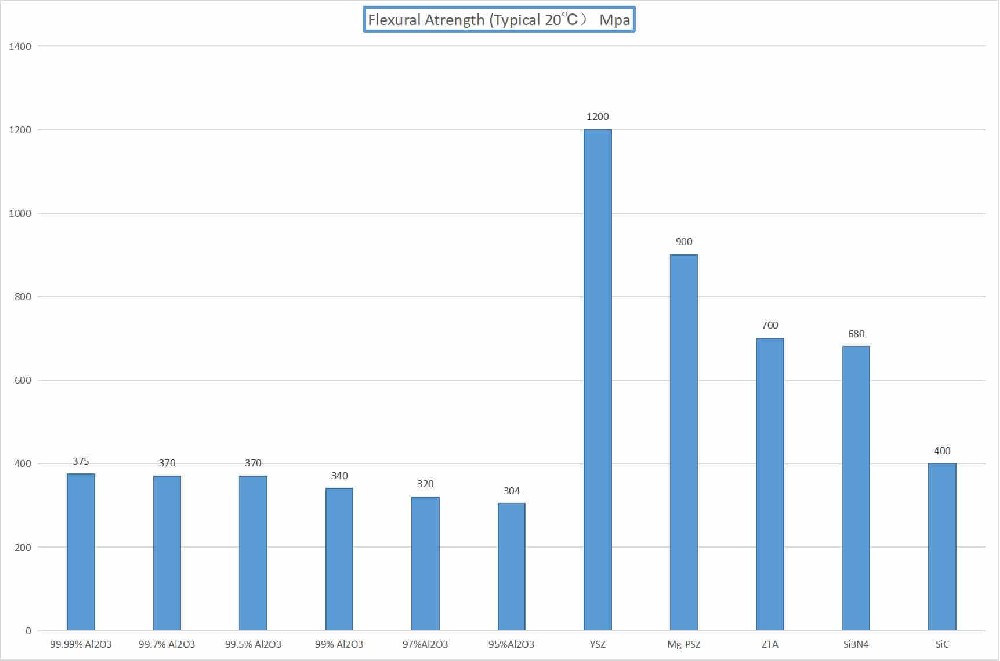

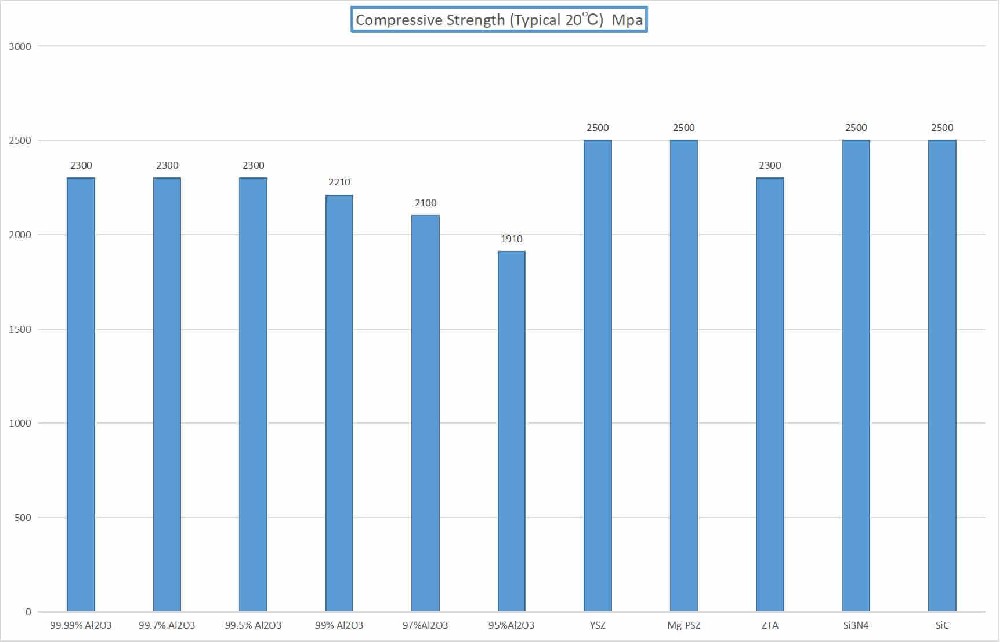

The temperature that ceramics can withstand varies according to their types, generally above 1000 degrees. For example, daily and art ceramics can withstand about 1100 degrees,industrial ceramics can reach 1280-1340 degrees, and some special products can even reach 1400 degrees. The heat resistance of industrial ceramics is more excellent, such as alumina ceramics can withstand about 2050 degrees, silicon nitride ceramics and silicon carbide ceramics can withstand high temperatures of about 2800 degrees and 2500 degrees, respectively.

Overview of high temperature resistance of ceramics

As an inorganic non-metallic material, ceramics have excellent high temperature resistance. Different kinds of ceramics, due to their differences in material and production process, can withstand different temperatures. Generally speaking, the heat resistance temperature of ceramics is above 1000 degrees, which makes ceramics have a wide range of application prospects in high temperature environments.

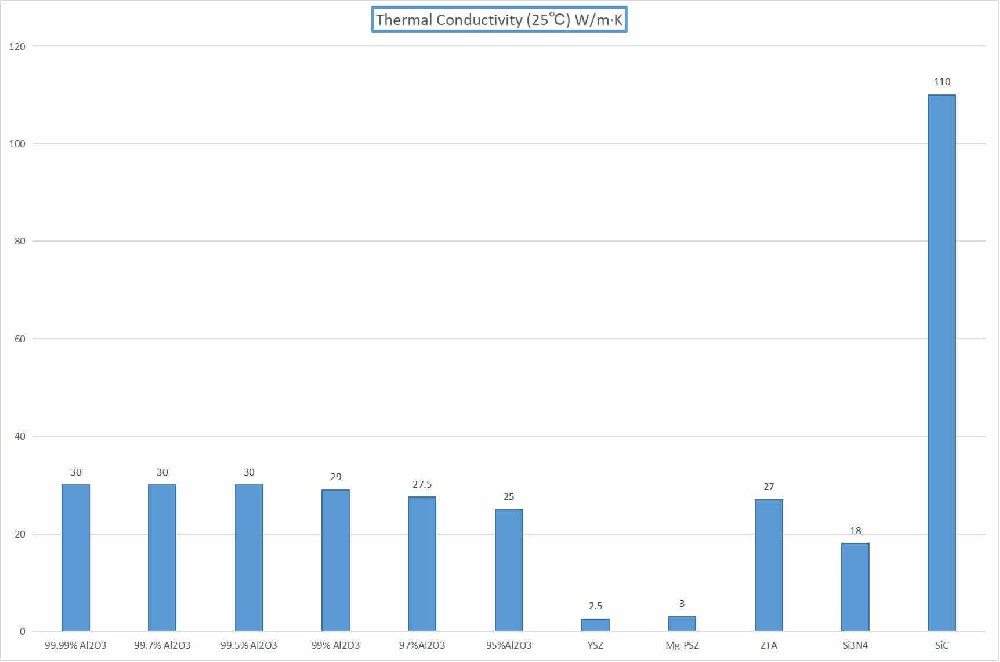

Industrial ceramics are mainly used for industrial production in harsh environments such as high temperature, high pressure and corrosion. The heat resistance of such ceramics is usually better. For example, alumina ceramics have excellent high temperature resistance and a melting point of about 2050 ° C, which can maintain stable performance at very high temperatures. The temperature resistance of silicon nitride ceramics and silicon carbide ceramics also reached about 2800 degrees and 2500 degrees, respectively.

Factors affecting high temperature resistance of ceramics

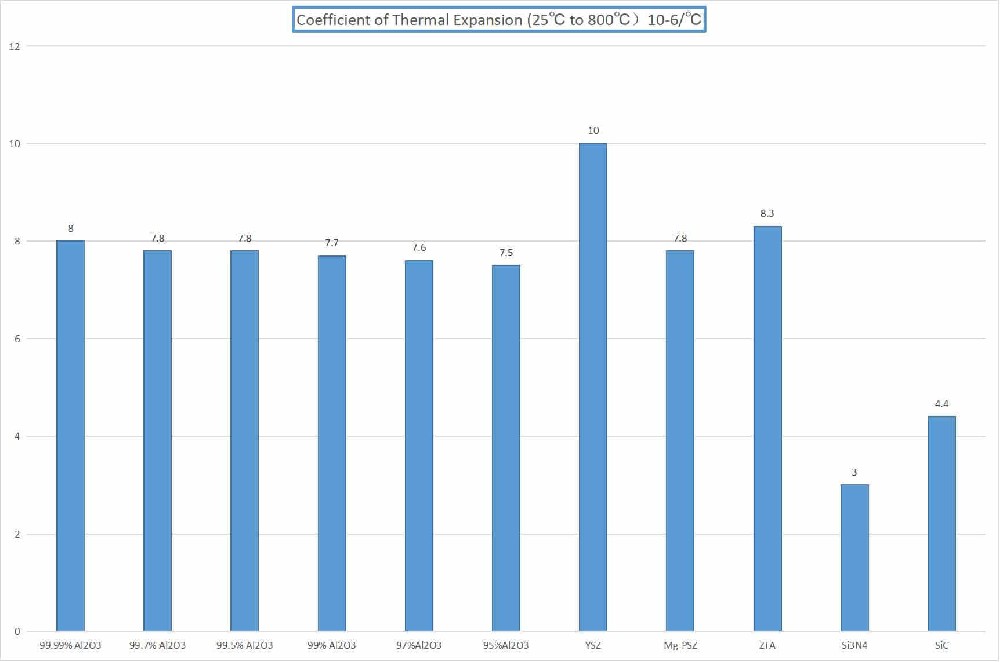

The high temperature resistance of ceramics is mainly affected by its material, production process and sintering temperature. In general, the higher the sintering temperature, the more complete the crystalline quality of the ceramic, the larger the size of the crystal, and the better its physical properties and high temperature resistance. In addition, the application field of ceramics will also have an impact on its high temperature resistance. For example, electronic ceramics need to have better insulation and electrical conductivity, so special attention needs to be paid to controlling these performance parameters during their production.

Thermal properties of ceramics

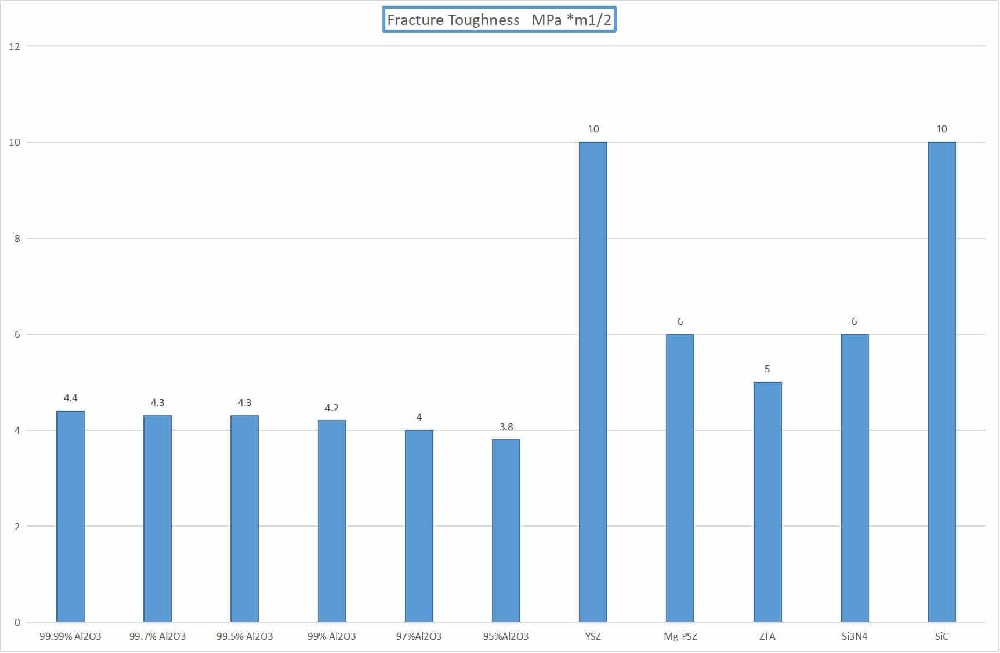

Ceramic has high insulation properties and stability, can withstand high temperature, impact resistance, not easy to deformation, its thermal expansion coefficient is low, not easy to be affected by thermal expansion and cold shrinkage changes.

Ceramics decompose, melt or sinter when heated, and different types of ceramics have different properties at high temperatures. Ordinary ceramic can withstand the temperature of about 700 ° C, while high temperature ceramics (alumina, zirconia, titanium oxide, etc.) can withstand high temperatures of up to 1700 ° C or more. Sapphire is a kind of high-temperature ceramic, its melting point is as high as 2050 ° C, which is widely used in high-temperature industrial environments and waterproof watch mirrors for divers.

Application areas of thermal properties of ceramics

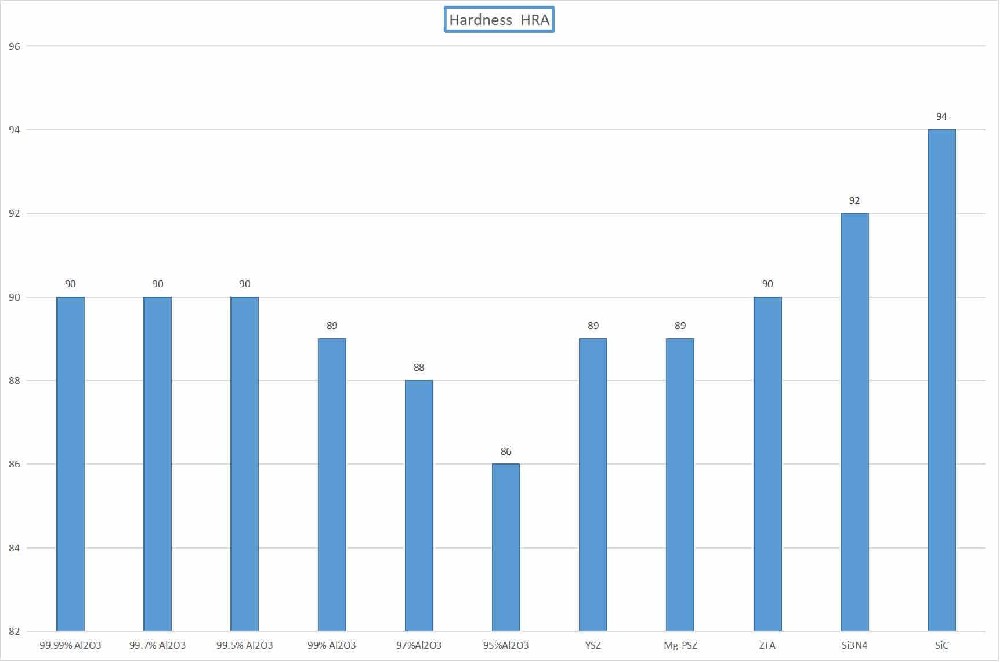

1. Machining field: Ceramic materials are widely used in artificial joints, pneumatic valves, high-speed bearings, grinding wheels and other machine parts because of their high hardness, no deformation and high straightness, which improves mechanical accuracy and service life.

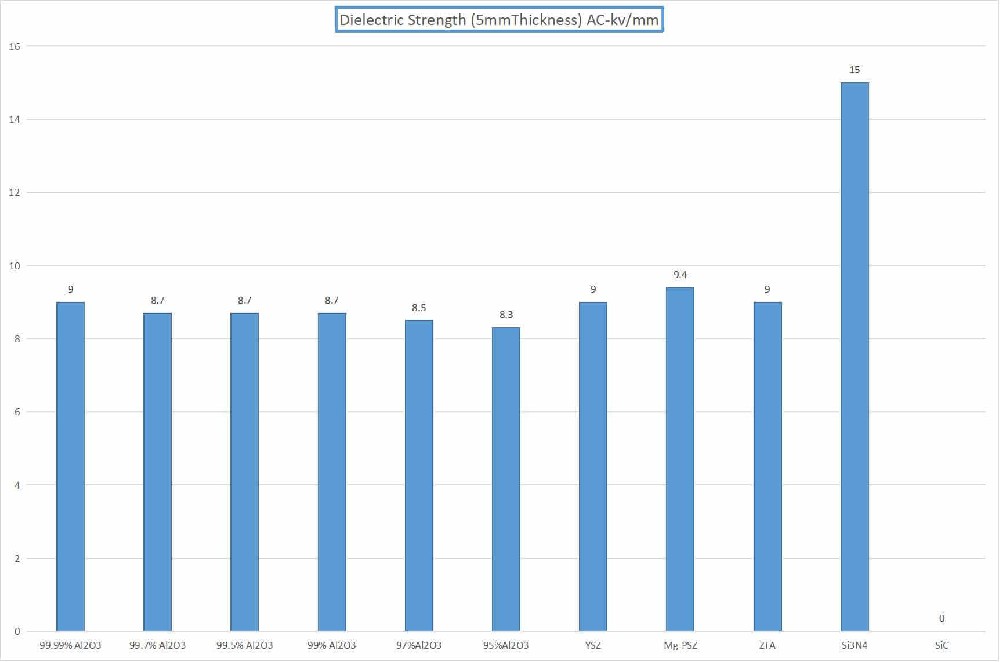

2. Electronic field: ceramics have good insulation properties, excellent electrical properties and stable dielectric constant, and are often used in the manufacture of capacitors, thermistors, insulating materials, etc.

3. Medical field: Ceramics are widely used in medical instruments such as artificial bones, artificial joints, artificial teeth and so on due to their biological inertia, corrosion resistance, wear resistance, and not easy to produce heat sensitivity and hot ice, improving many problems in the field of modern medicine.

In general, ceramics decompose, melt or sinter when exposed to heat, but different types of ceramics have different thermal properties. With the development of advanced production technology, ceramic products have a wide range of application prospects in the fields of electronics, medicine, machinery, etc., and the improvement of its thermal properties will further increase the scope of application of ceramics.