Ceramic Fracture Toughness

Fracture toughness is a measure of the fracture strength of a material with a cracked surface or inside (cracked material). Fracture toughness is the ability of a material to resist crack propagation, is an intrinsic property, and has nothing to do with the size, shape and external force of the crack. Ceramic materials are very sensitive to cracks, fracture toughness is an important index to evaluate the mechanical properties of ceramic materials, and the problem of crack propagation and fracture is commonly studied in linear elasticity.

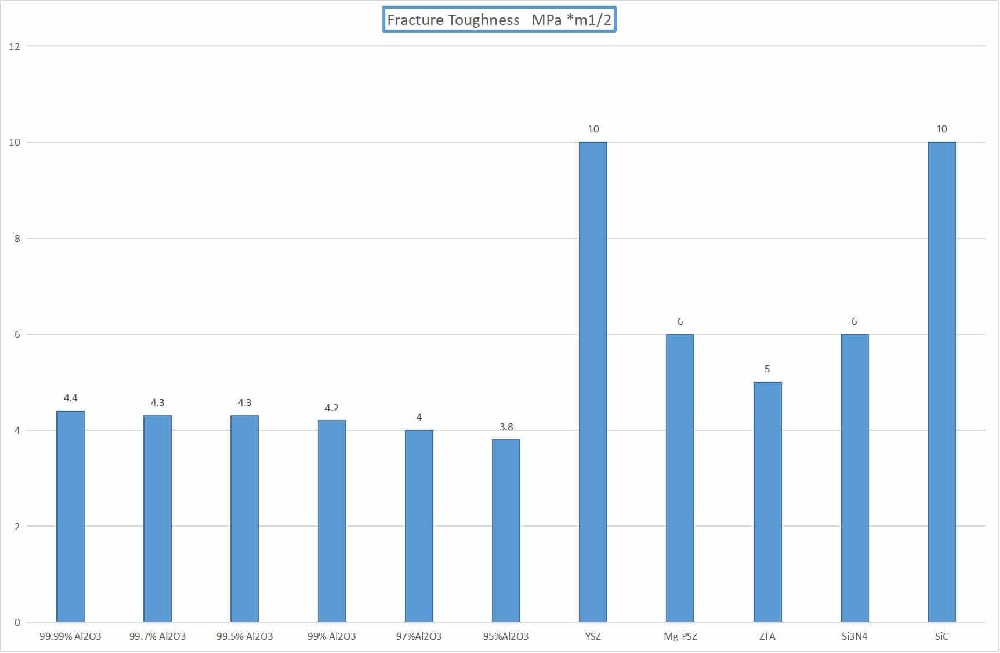

Fracture toughness range of ceramics

The fracture toughness of ceramics usually ranges from 1 to 10 MPa·m^0.5, but it can be improved by doping, improving the microstructure, or using new materials and technologies. For example, zirconia ceramics through phase change toughening technology, its fracture toughness can reach 10 ~ 30 MPa·m^0.5.

Ceramic materials are widely used in many fields because of their high hardness and good wear resistance. However, the brittleness of ceramics also limits its scope of use. Therefore, it is very important to understand and improve the fracture toughness of ceramics.

General range of fracture toughness of ceramics

The fracture toughness of ceramics is an important index to measure its ability to resist crack propagation. Generally speaking, the fracture toughness of ceramics ranges from 1 to 10 MPa·m^0.5. The values in this range show that the ceramic has a certain resistance to crack propagation when subjected to external forces, but it is relatively weak.

As a brittle material, ceramics are prone to crack and eventually fracture when subjected to external forces. Fracture toughness refers to the ability of a material to resist further expansion when it is subjected to external loads causing cracks, which is a measure of the energy that the material can absorb before it breaks. Therefore, fracture toughness is one of the important indexes to evaluate the tensile and bending resistance of ceramic materials.

1. Material composition: The composition of ceramics determines its performance indicators, including fracture toughness is no exception. For example, adding an appropriate amount of additives such as ZrO2 or Al2O3 can significantly improve the fracture toughness of ceramics.

2. Preparation process: The preparation process of ceramics also has a great impact on its fracture toughness. For example, the use of evenly distributed oxide particles to pre-add raw materials, strengthen sintering and other methods can improve the internal properties of ceramic materials.

3. Loading rate: Loading rate is also one of the factors affecting the fracture toughness of ceramics. Under fast loading, the ceramic will crack quickly, while under slow loading, the ceramic has more time to form cracks, resulting in a decrease in its fracture toughness.

Improvement method

1. Control material composition: By controlling the type and proportion of additives and optimizing the proportion of ceramic components, the fracture toughness of ceramics can be improved.

2. Improve processing technology: The use of new technology, new equipment and other methods can improve ceramic processing technology, improve ceramic performance, but also improve the fracture toughness of ceramics.

3. Heat treatment: Through high or low temperature heat treatment of ceramics, its microstructure can be changed to a certain extent, thereby improving the fracture toughness of ceramics.