Ceramic Hardness

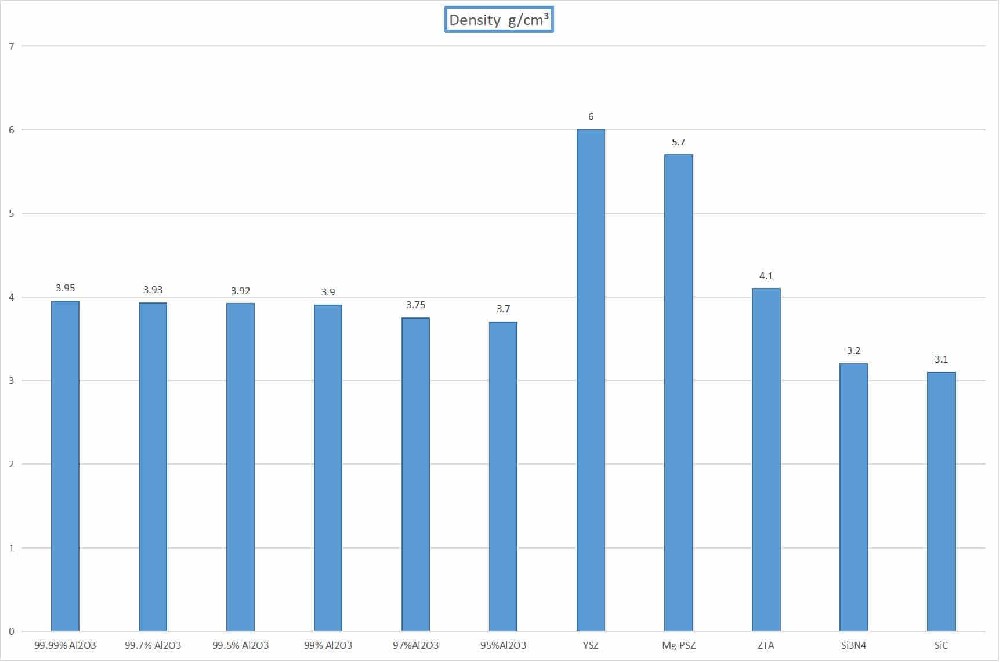

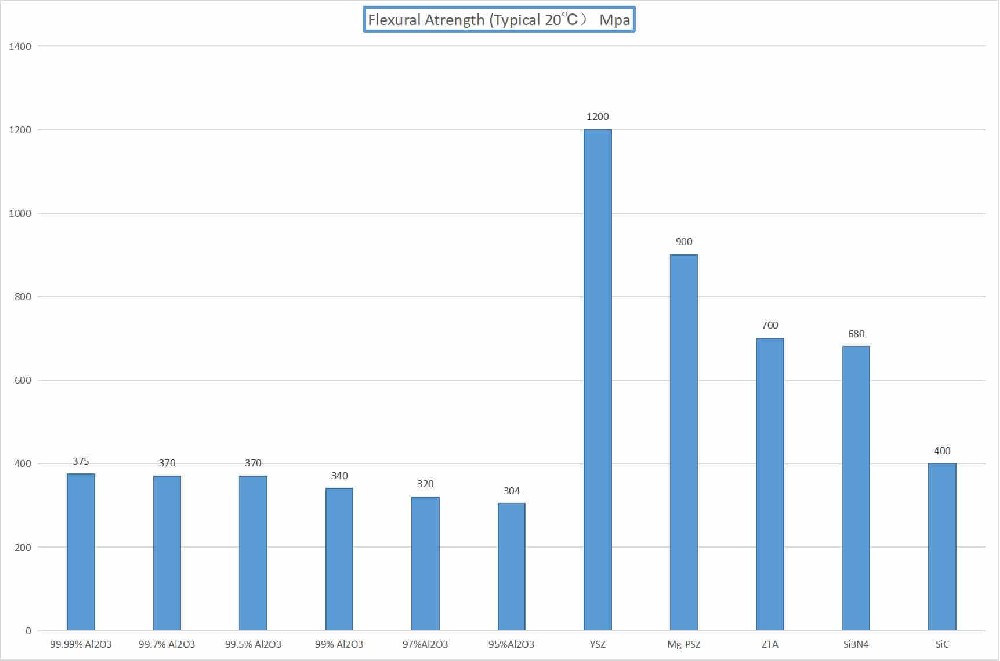

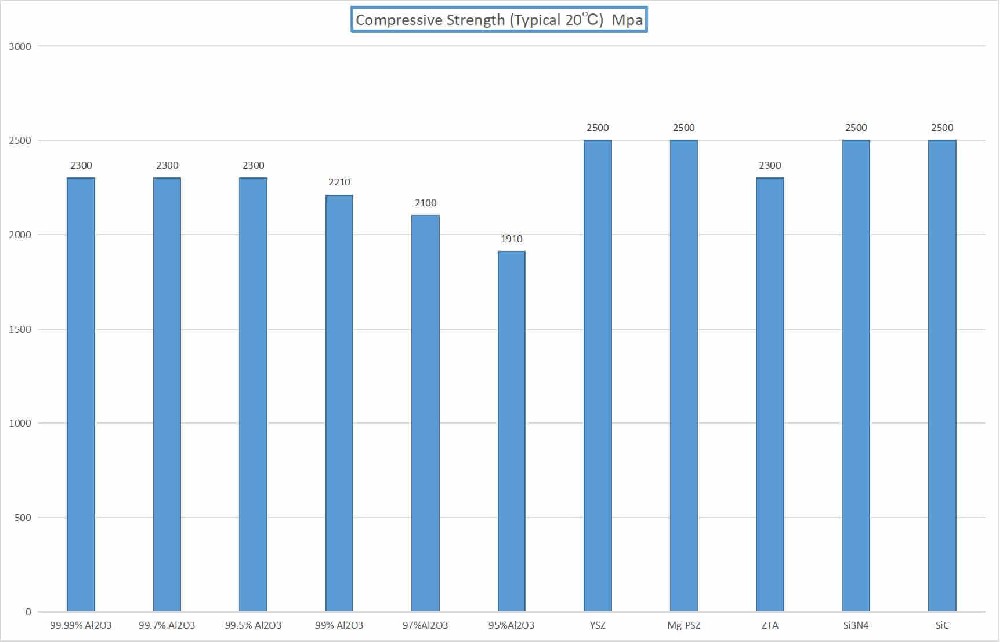

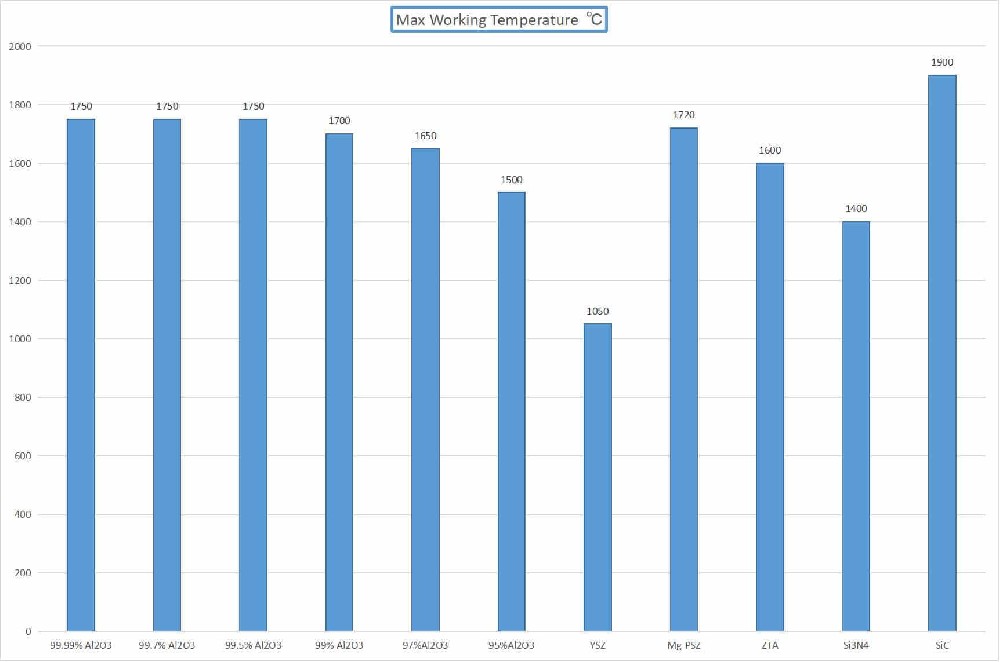

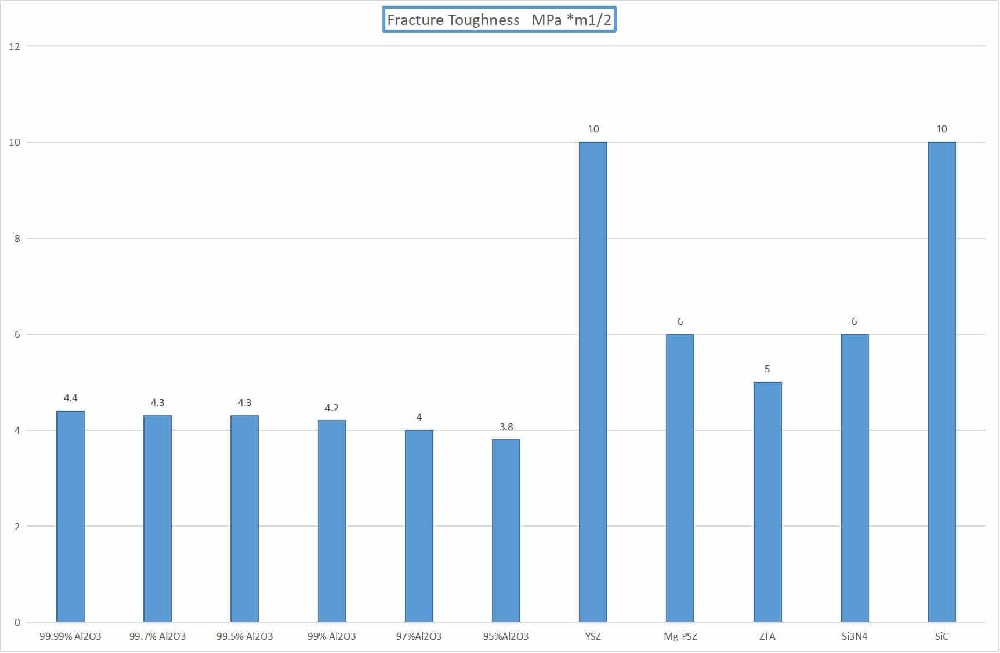

The hardness of industrial ceramics is generally between 5 and 8.5, and the hardness is mostly above 1500HV (Vickers hardness), depending on its material composition and optimization process. Among them, the hardness of alumina ceramics (Al2O3) can reach 9 (Mohs hardness tester), so it is one of the most common industrial ceramic materials. In addition, silicon carbide ceramics, silicon nitride ceramics also have a high hardness. This high hardness makes industrial ceramics excellent in wear resistance and pressure resistance, and is widely used in various mechanical and industrial fields.

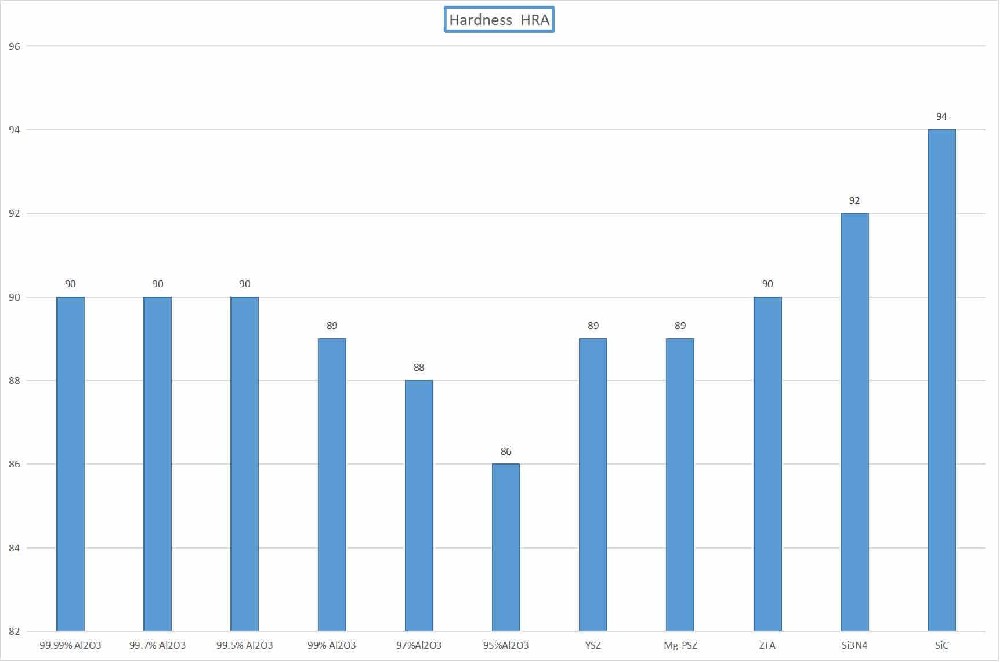

Hardness comparison of different types of industrial ceramics

Alumina ceramics : hardness up to 9, HRA80-9012.

Silicon carbide ceramics and silicon nitride ceramics : also have a higher hardness 1.

Zirconia ceramics : hardness varies with the composition, for example, the hardness of 95% zirconia ceramics is 9.0, the hardness of 80% is 8.0, and the hardness of 65% is 7.53.

First, what is ceramic hardness?

Ceramic is a kind of non-metallic inorganic amorphous or crystalline material, because of its unique mechanical, electrical, optical and chemical properties, is widely used in manufacturing, construction, life science and other fields. Among them, the hardness of ceramics is one of its important mechanical properties. Hardness is a substance's ability to resist force, often used to indicate how easy it is to press into the surface of an object, it is widely used in the testing of metals, plastics, ceramics and other materials.

Hardness is a test method used to measure the hardness of a material, which calculates the hardness of the surface of a sample by applying pressure to it. The hardness measure is determined by a physical experiment measurement, and hardness is defined as the ratio between the pressure exerted by an object whose mass is increased during the test and the diameter of the impression created when a standard ball size passes through the specimen.

Ceramic hardness refers to the value obtained when the ceramic material is tested for hardness. Due to the high hardness of ceramic materials, large-size standard balls are usually used for testing to reduce measurement deviation.

Second, the application field of ceramic materials

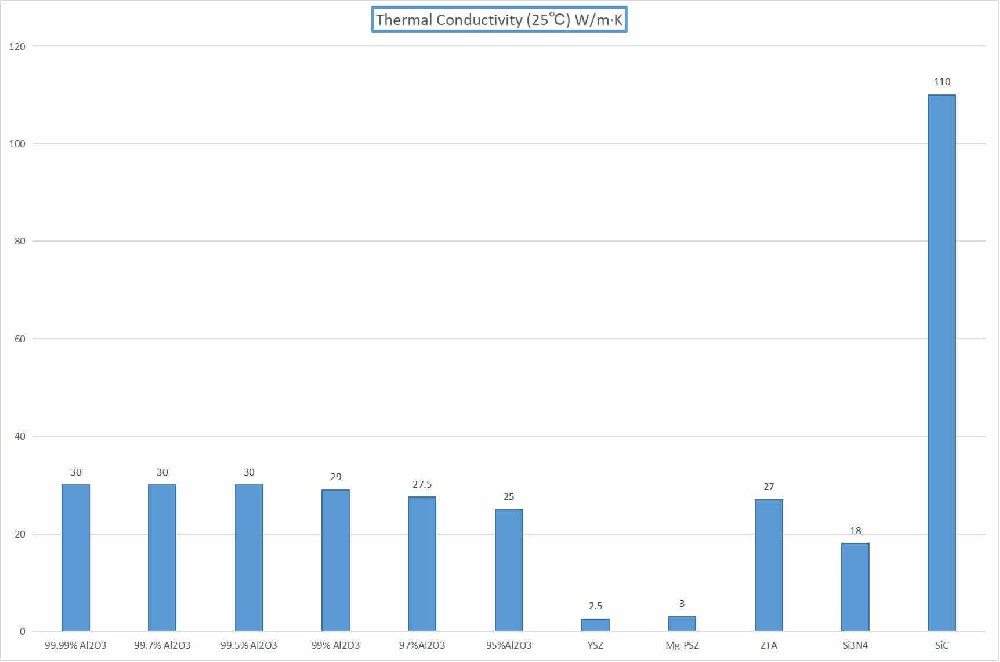

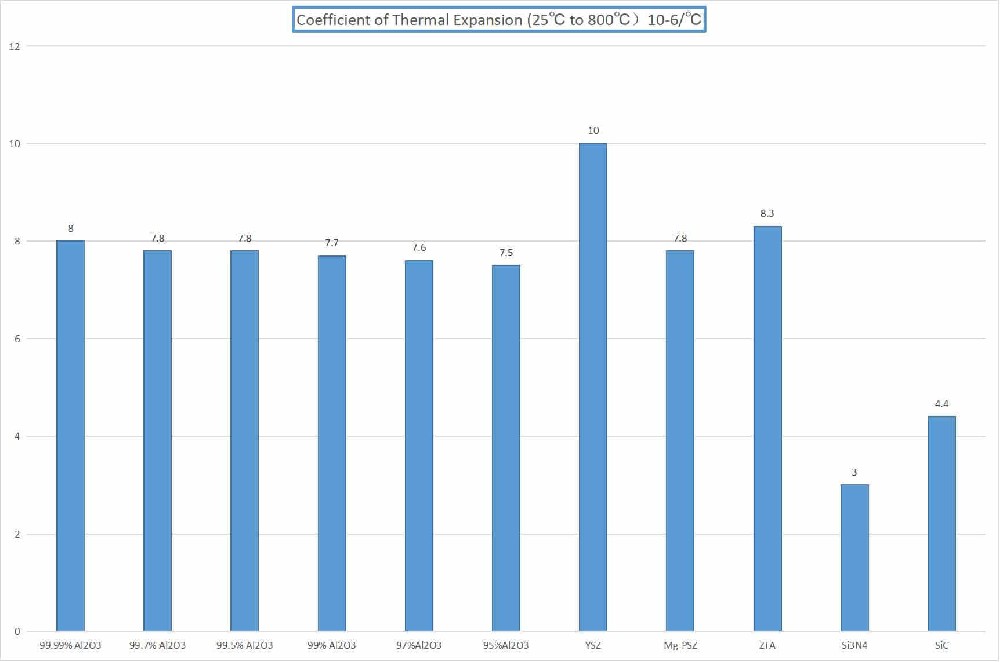

Ceramic materials have the characteristics of high hardness, wear resistance, corrosion resistance, insulation, thermal conductivity, etc., so they are widely used in manufacturing, engineering and life science fields.

1. Manufacturing field

Ceramic materials are widely used in the manufacturing industry to manufacture parts and devices with high density, high strength and high hardness. For example, they are used in the manufacture of grinding tools, high temperature stoves, bearings, synthetic tools, mechanical seals, etc.

2. Engineering field

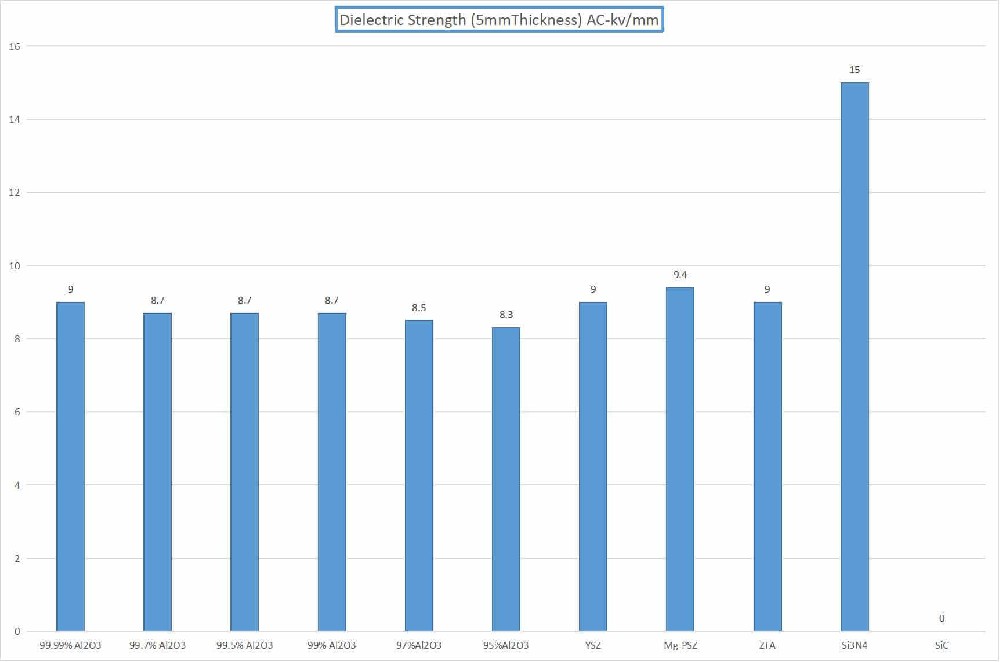

Ceramic materials are widely used in the engineering field to manufacture components and components with high strength, high hardness, high temperature stability and chemical stability. For example, they are used in the manufacture of aero engines, automotive engines, gas turbine blades, cylinder liners, valves, pipes and high voltage electrical insulation.

3. Life sciences

Ceramic materials are widely used in the field of life sciences, for example, they are used in the manufacture of artificial bones, artificial teeth, artificial heart valves and other medical devices, while they are also used in research fields, such as the manufacture of cell vectors and biosensors.

In the field of engineering, with the increasing development of hydrogen energy technology and clean energy technology, the application of ceramic materials in the field of new energy and environmental protection will also be further expanded. For example, ceramic materials are used in the manufacture of hydrogen batteries and clean energy devices.

Finally, in the field of life sciences, with the continuous development of gene editing and artificial intelligence technologies, ceramic materials will play a greater role in creating higher-level and more efficient life science laboratories and technical equipment.

Overall, ceramic hardness plays a key role in the application of ceramic materials. With the continuous development and progress of science and technology, the application of ceramic materials will continue to expand and improve. This shows that ceramic materials will play a more important role in the future development of science and technology.