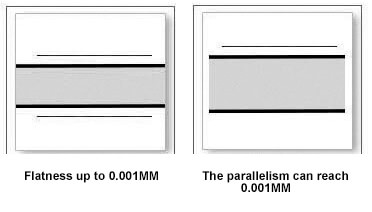

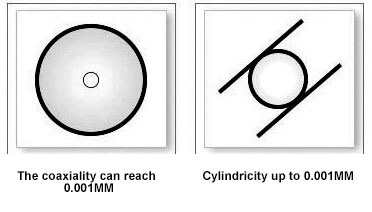

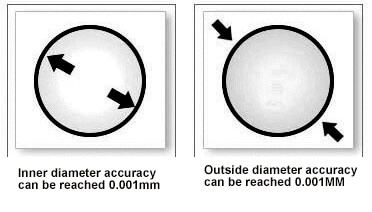

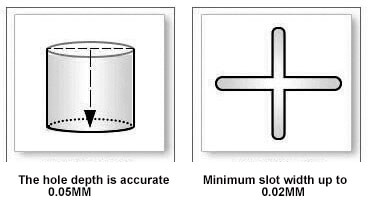

Manufacturing equipment and precision dimensions

We manufacture advanced precision ceramic products

The company offers one to stop service, from forming, sintering, processing and inspection,mainly accepting customization based on drawings and samples.

For example: zirconia, alumina, silicon nitride, aluminum nitride, silicon carbide ceramics and other precision parts, precision structural parts, petrochemical ceramic pump, ceramic rod/needle, ceramic tube/ring, ceramic plate/plate, ceramic bushing, ceramic plunger, medical/food ceramic pump and other products finishing.

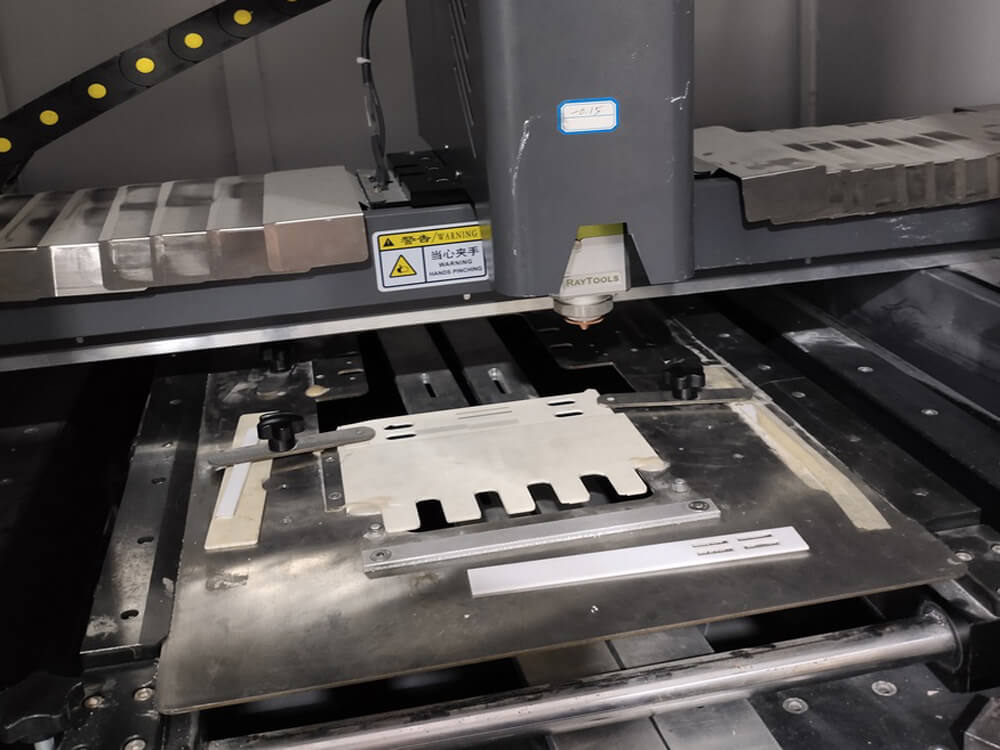

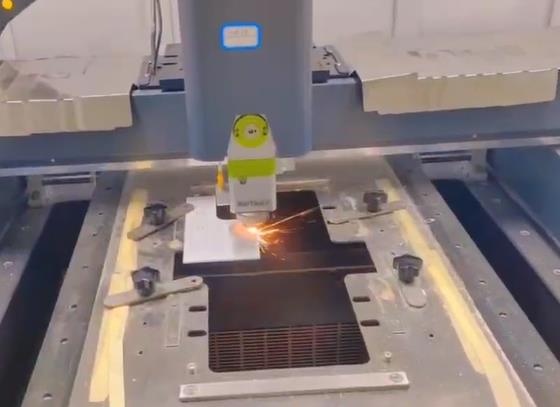

- Using high-precision ceramic engraving and milling machines and other machinery, the tolerance range can be provided is 1um

- According to the actual needs of customers, provide ceramic component design, and provide matching ceramic materials

- Provide the fastest delivery of expedited customized services to meet customer emergency proofing, production needs, design schedule.

Support custom precision ceramic parts and sample testing

General manufacturing process of ceramic parts

- 1. Material preparation: Select the appropriate ceramic material according to the design requirements, and pre-treatment such as cutting and polishing.

- 2. General processing: The use of grinding, EDM and other methods for preliminary processing of ceramic parts, remove excess materials, to achieve the design requirements of the approximate shape and size.

- 3. Precision machining: Using grinding, ultrasonic, laser and other methods to fine machining alumina ceramic parts, improve dimensional accuracy and surface quality.

- 4. Polishing: polishing the ceramic parts to improve the surface finish and reduce the surface roughness.

- 5. Inspection: The ceramic parts size, shape, surface quality and other aspects of the inspection, to ensure that product quality meets the design requirements.